Mounting and Installation Notes D661/2/3/4/5 (B97072-660-001; Version G, 02/15) Page 3/3

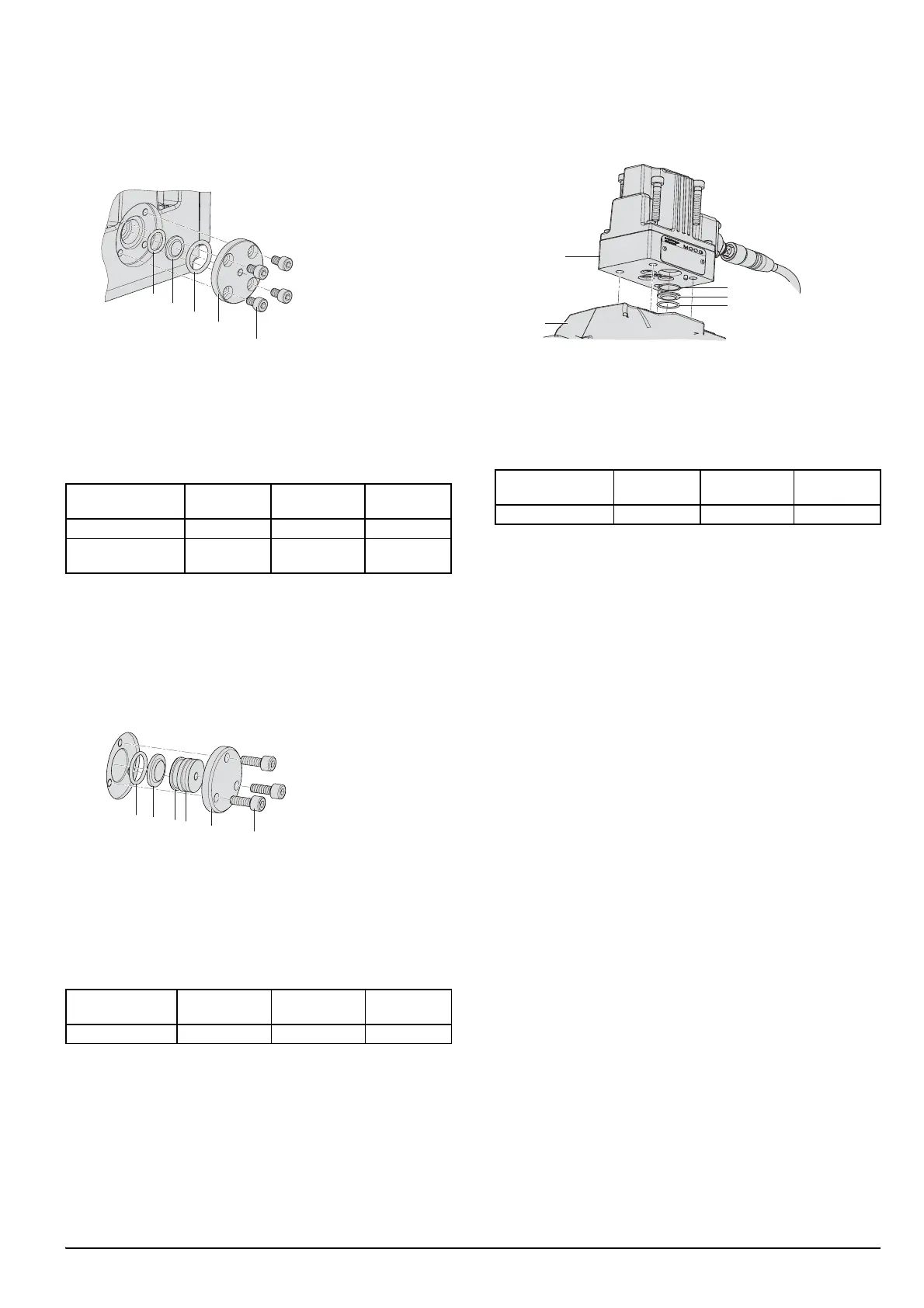

Applies only for D661 and D665 with D661 and D631 as pi-

lot valve

• Remove hexagon socket screws (5) with a wrench and

remove the filter cover (4). Remove the filter disk (2),

which is now accessible, with tweezers or a fine screw-

driver.

Fig.: Principles of construction

• Check O-rings (1) and (3) and replace if necessary.

• Install new filter disk. To do this, first insert the O-Ring

(1), then the filter disk (2) so that the side of the filter disk

with the indentation faces the outside. Insert O-ring (3) in

the filter cover (4) with some clean grease and mount.

• Torque screws to:

• After start-up, check valve for external leakage.

Applies only with -630 (D630) pilot valve

• Remove hexagon socket screws (6) with a wrench and

remove the filter cover (5). Pull out the plugs (4) using an

M4 screw. Remove the filter disk (2), which is now acces-

sible, with tweezers or a fine screwdriver.

Fig.: Construction

• Check O-rings (1) and (3) and replace if necessary.

• Install new filter disk. To do this, first insert the O-Ring

(1), then the filter disk (2) so that the side of the filter disk

with the indentation faces the outside. Insert O-ring (3) in

the plugs (4) with some clean grease and mount.

• Torque screws to:

• After start-up, check valve for external leakage.

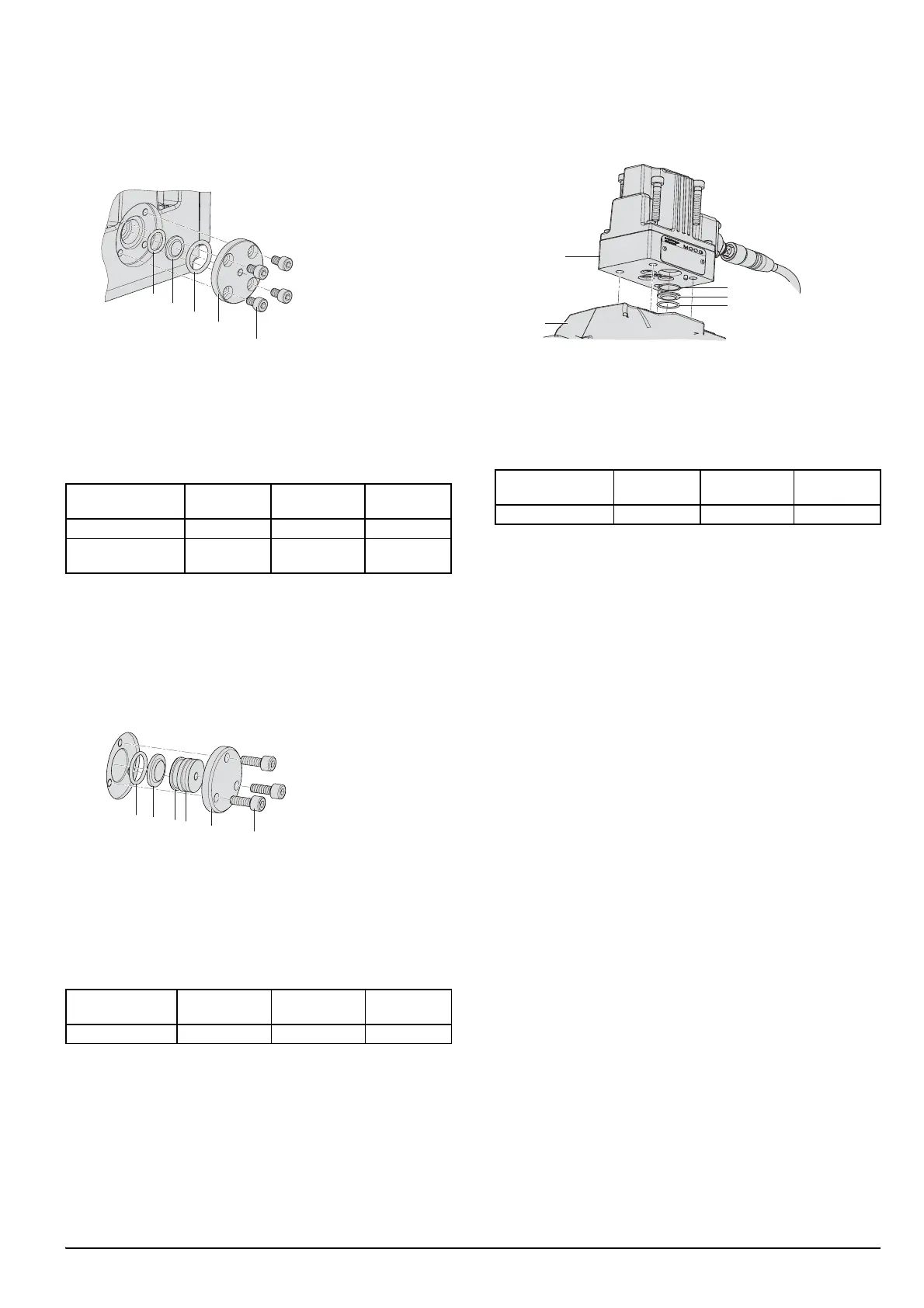

Applies only with D061 pilot valve

• Loosen pilot valve (2) from the main stage (1). Remove

the filter disk (4), which is now accessible, with tweezers

or a fine screwdriver.

Fig.: Construction

• Check O-rings (3) and (5) and replace if necessary.

• Install new filter disk. To do, first insert the O-Ring (5),

then the filter disk (4) and O-ring (3) so that the side of

the filter disk with the indentation faces the outside.

• Cross-torque screws to:

• After start-up, check valve for external leakage.

Replacing O rings: The mounting surface O rings may be re-

placed by the customer (on the pilot valves and the way valves

as well). The O rings of the pilot valve and way valve of the

D661 must not be replaced by the customer. Pay attention to

cleanliness of the valve and of the surroundings.

Transportation/storage: Before transportation, seal the base

of the valve using a clean shipping plate or adhesive tape.

Seal the connector using a dust protection cap. Pack the valve

carefully so that it is not damaged during transportation or stor-

age.

Inspection: Following a period of storage or no operation for

more than 5 years, we recommend that the valve is inspected

by an authorized service center, in order to prevent possible

damage.

Repairs: Repairs may only be carried out by us or by our au-

thorized service centers.

9 Disposal

It is essential to comply with the relevant national waste dis-

posal regulations and environmental protection provisions

when disposing of valves, spare parts or accessories, packag-

ing that is no longer needed, hydraulic fluid or auxiliary materi-

als and substances used for cleaning!

Type Series Screw

Torque

[Nm] (lbf in)

Pilot valve D631 M4 x 10–10.9 4.70 (41.6)

Pilot valve/

Proportional valve

D661 M5 x 8–10.9 8.34 (73.8)

Type Series Screw

Torque

[Nm] (lbf in)

Pilot valve -630 (D630) M4 x 10–8.8 3.40 (30.1)

Type Series Screw

Torque

[Nm] (lbf in)

Pilot valve D061 M5 x 30–10.9 8.34 (73.8)

Loading...

Loading...