The Interface Solution Experts 11

FDY

PC-Programmable Frequency

Transmitter and Display

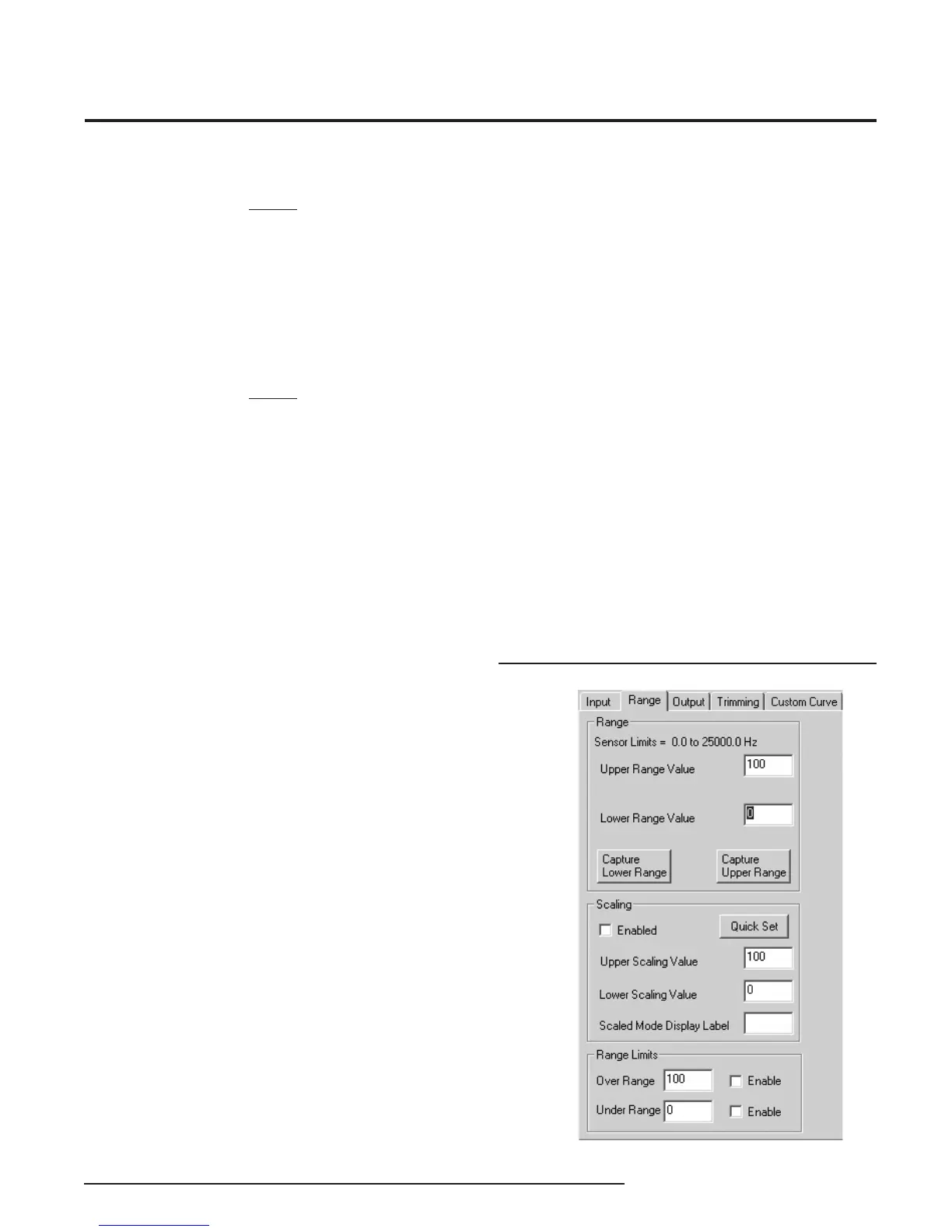

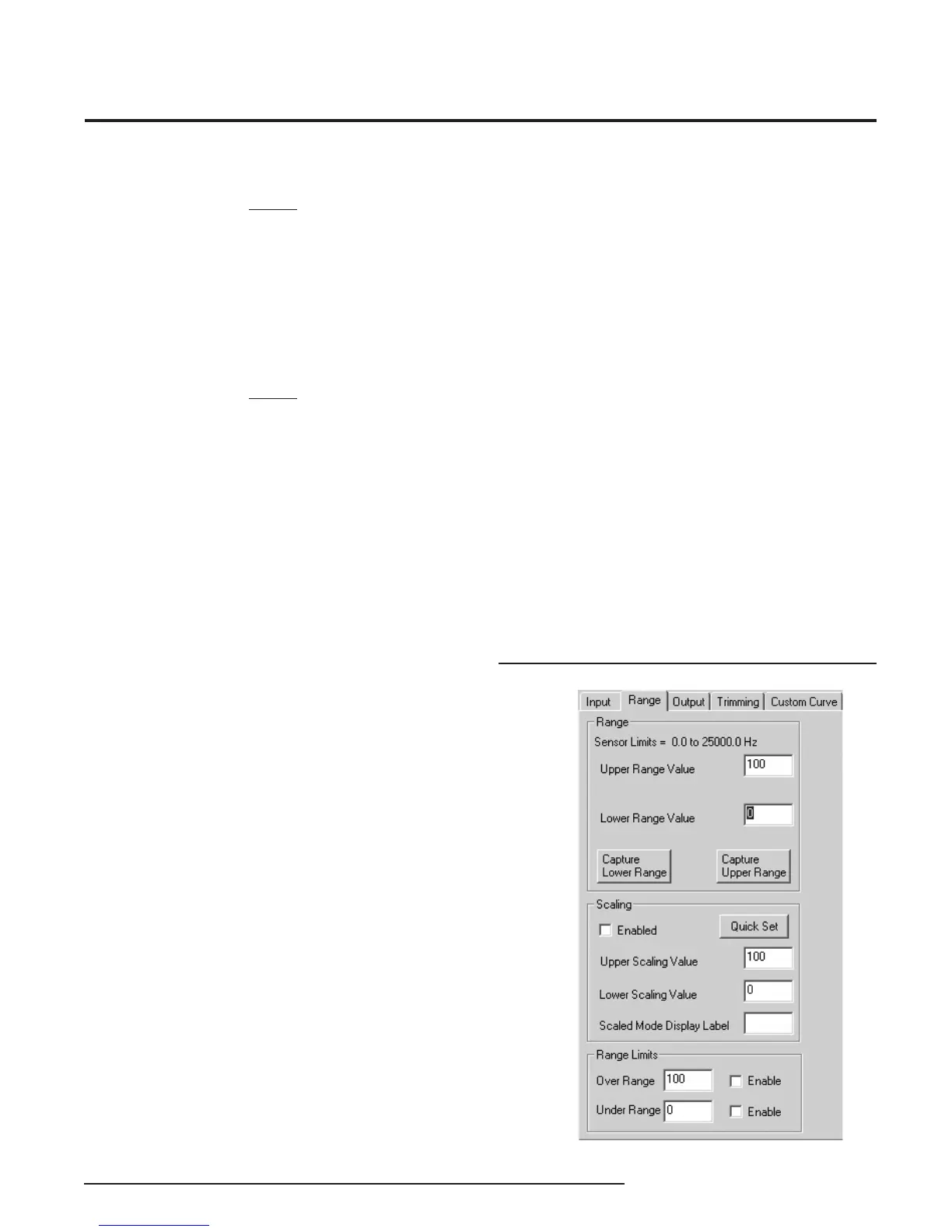

Programming the Range Parameters

The Range tab permits you to set or capture the

acceptable input range and establish range limits.

• Use the Lower Range Value cell to set the input

value that will correspond to a 4mA output. In the

same way, use the Upper Range Value to set the

input value that corresponds to a 20mA output.

• Reverse the output (causing the output to increase

as the input decreases) by setting the Lower

Range Value higher than the Upper Range Value.

• The Capture Lower Range and Capture Upper

Range buttons permit you to trim the upper and

lower range of the sensor (if necessary). Just click

the appropriate button to begin trimming.

Figure 8. Range Parameters Tab

NOTE:

If the Lower Range Value is set to 0Hz in the Input

Range the Fail On Input Time-out feature will not be

available, the Lower Range Value must be set to a

value greater than zero to enable this feature (box

must be checked to apply feature) .

Low Pass Filter Enable: Reduces noise by fi ltering out

high frequency signals.

NOTE:

Moore Industries recommends having the Low-Pass

fi lter turned on when the upper input range value is

less than 150Hz (especially on the 10VAC - 250VAC

units).

Averaging Filter: Shows the number of readings

the FDY averages together to provide the displayed

reading. This can be used to compensate for bent

blades in a monitored turbine by setting the value to

equal the number of blades on the turbine. (i.e. if the

turbine has four blades, set the Averaging Filter to 4).

Minimum Debounce Period: Available only when

contact closure is selected in measurement mode.

This value eliminates noise from a contact closure

input, but lowers the maximum measurable frequency.

After selecting the input parameters, continue

by clicking the Range tab and proceeding to the

Programming the Range Parameters section.

You are given the option of scaling your process

variable reading. To do this, click the Enabled check

box in the Scaling section. Scaling allows you to take

your process variable and manipulate the reading to a

more customized range.

• In the Upper Scaling Value text box, enter the

value you wish displayed when your input is at its

full range. Repeat the step for the value you wish

displayed when your input is at its zero value and

enter that into the Lower Scaling Value box.

At the Scaled Mode Display Label box, enter the

specifi c EGU (Engineering Unit) that you want as your

display.

• The Range Limits section allows you to designate

when the input will be considered bad (over or

under range). For example, if you have set the

Lower Range Value for 20, you can set the Under

Range for 10 and check the Enable box, allowing

the input to decrease below 10Hz before an error

is registered. In this case, the display shows

Under/Over range, and the output is in Failure

Mode (see Programming Output Parameters).

Loading...

Loading...