Page39SYSTEM

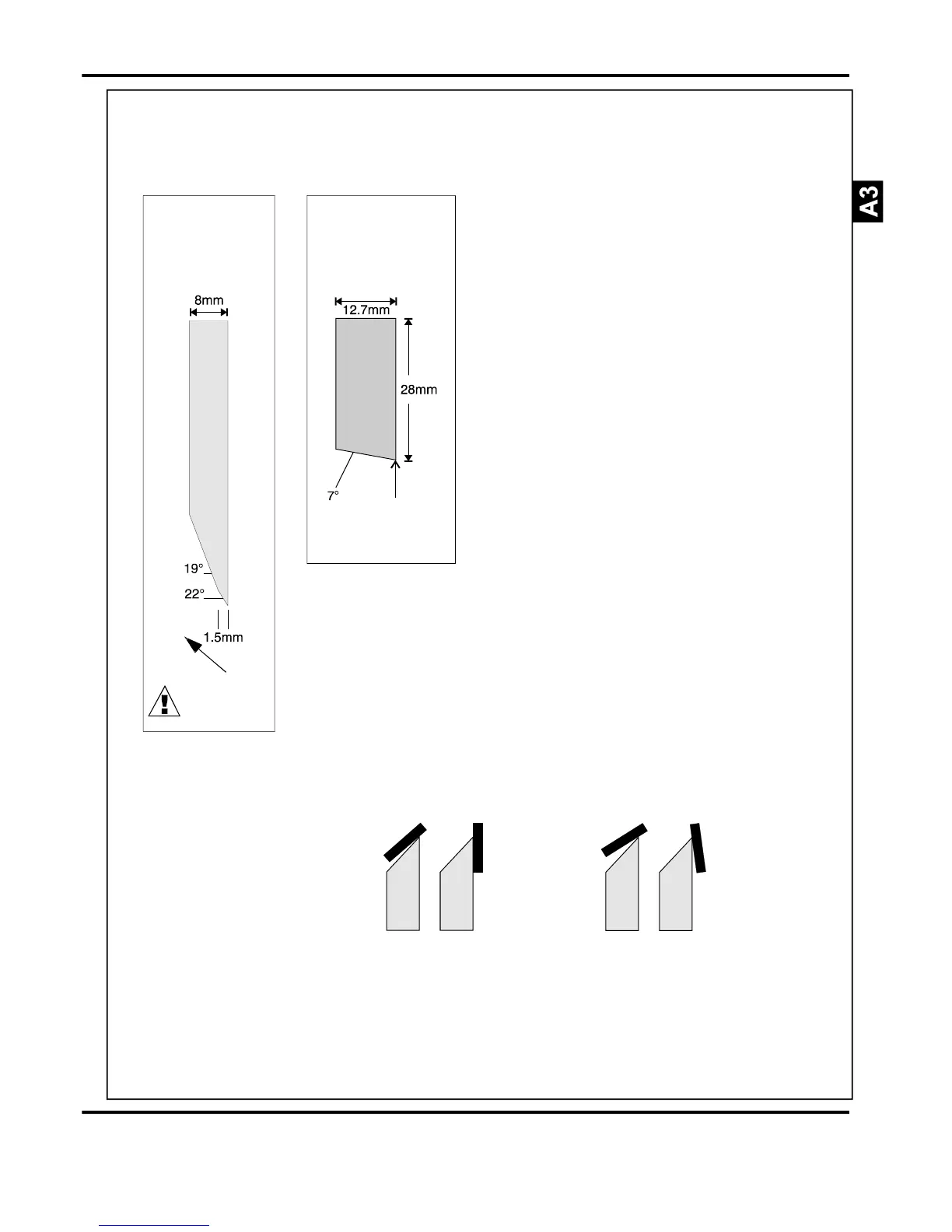

Note:

2facesmust

beflattowithin

0.03mm

Important:

GrindInThis

DirectionOnly

BLADE

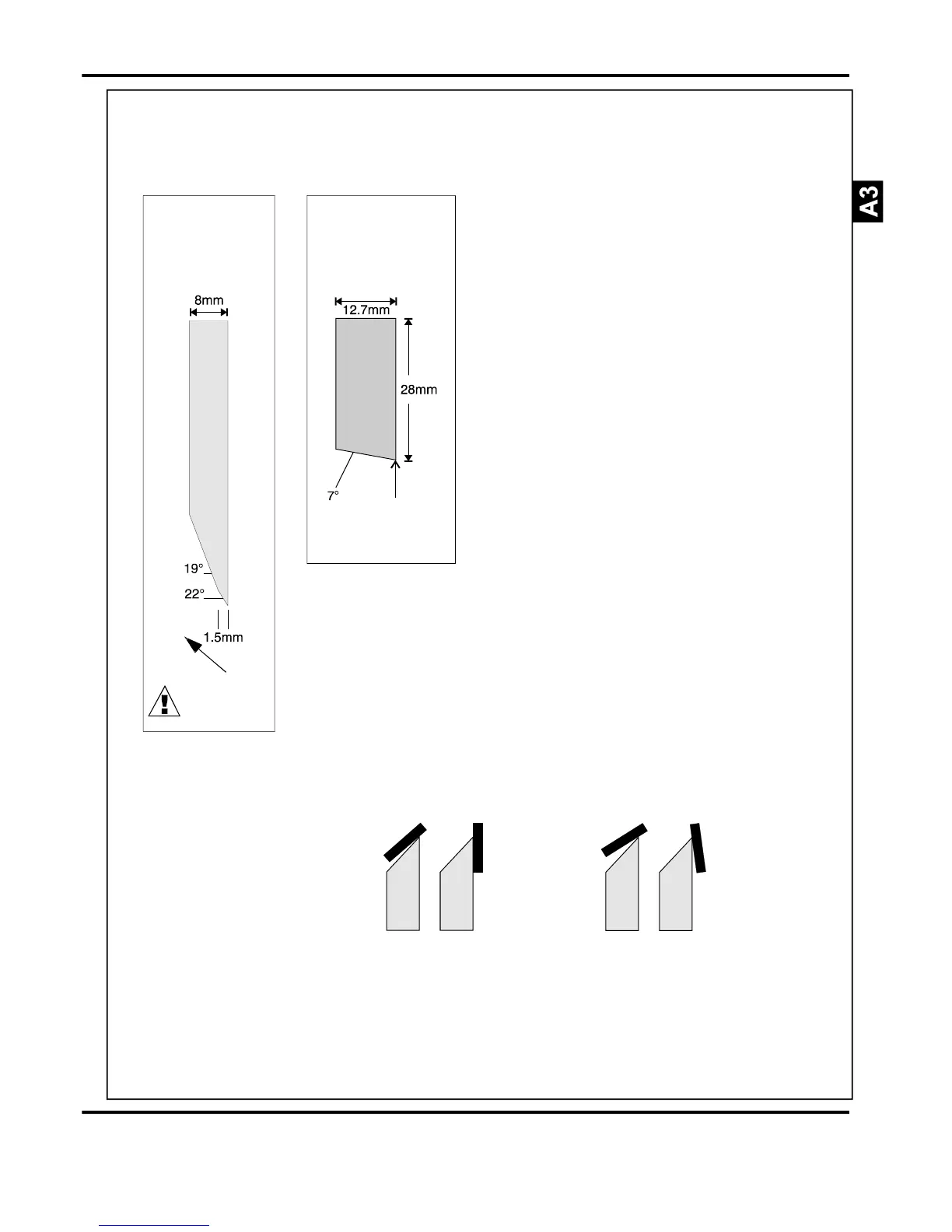

Note.

2facesmust

beflattowithin

0.01mm

Thisedgemust

bestraightto

within0.04mm

ANVIL

CorrectIncorrect

TrimMasterBladeGrindingInstructions

TrimMasterblade253-835isfittedwitha

guideleg.Thisberemovedwhenthe

bladeisregroundandrefittedafterwards.

BladeMaterialHighCarbonHigh

Chrome(AisiD2/D3)

GrindingAngleSeedrawingalongside

GrindingWheelCuporCylinder

GrindingMaterialGrit:46-60

Hardness:G-H

Bond:Vitrified

Peripheralspeed20-26(VM/S)

ofthegrindingwheel65-85(VFt/S)

TableSpeed20-26(VM/Min)

65-85(VFt/Min)

Feedperpass0.01-0.02mm

0.0004-0.0008"

Honing

Afterre-grinding,theburrshouldbecarefullyremoved

byhoning.Thequalityofhoningaffectstheusefullifeof

thecuttingedge.

Note:

must

DocuMasterPro

Loading...

Loading...