A-6 DAILY INSPECTION

4.3 Greasing the Chuck Master Jaws

If the master jaws are not lubricated properly with grease, the gripping force of the chuck will be

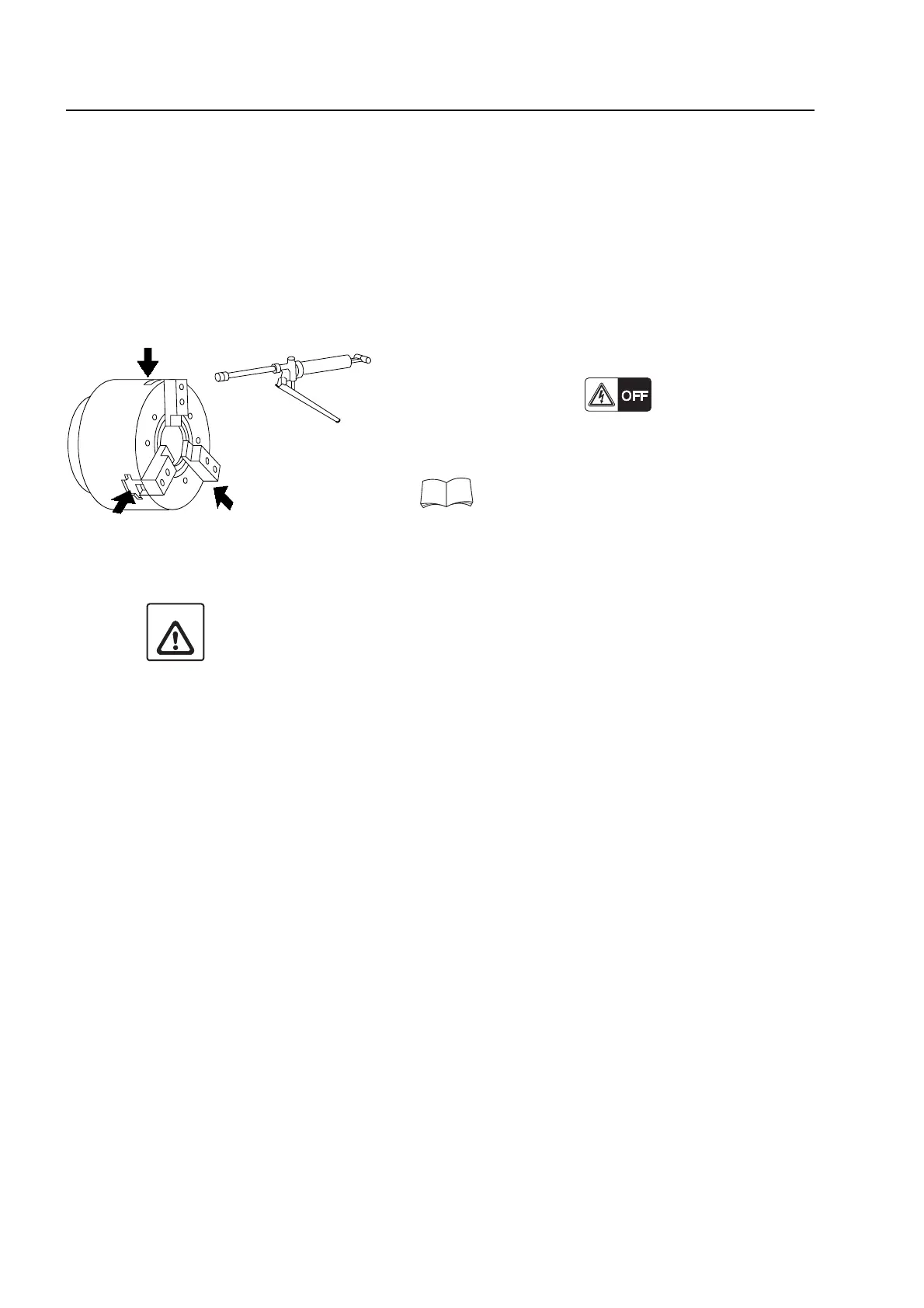

reduced. If the spindle is rotated while the master jaws are not properly greased, the workpiece

will fly out of the chuck, causing injuries and machine damage.

Apply grease to the master jaws at least once a day, before starting the day's operation.

<Procedure>

1) Stop the spindle.

2) Turn off the power.

3) Supply grease from the grease cup around the

chuck.

For the name and volume of the cooling oil,

refer to the OILING CHARTS in the

MAINTENANCE INFORMATION published

separately.

Coolant splashed on the chuck will wash away the grease. Therefore, supply grease

as often as possible.

CAUTION

Loading...

Loading...