B-38 REGULAR INSPECTION

15. ADJUSTING THE SETTING PRESSURE

15.1 Adjusting Hydraulic Unit Main Pressure

The hydraulic unit main pressure is factory-set to the required value. It is not necessary to set or

adjust the main pressure when the machine is installed.

Adjusting the main pressure is necessary when the piston pump is replaced.

The pilot valve provided on the pump unit is used to adjust the main pressure.

Make sure that no workpiece is mounted in the chuck when checking the main pressure.

<Procedure>

1) Turn on the power.

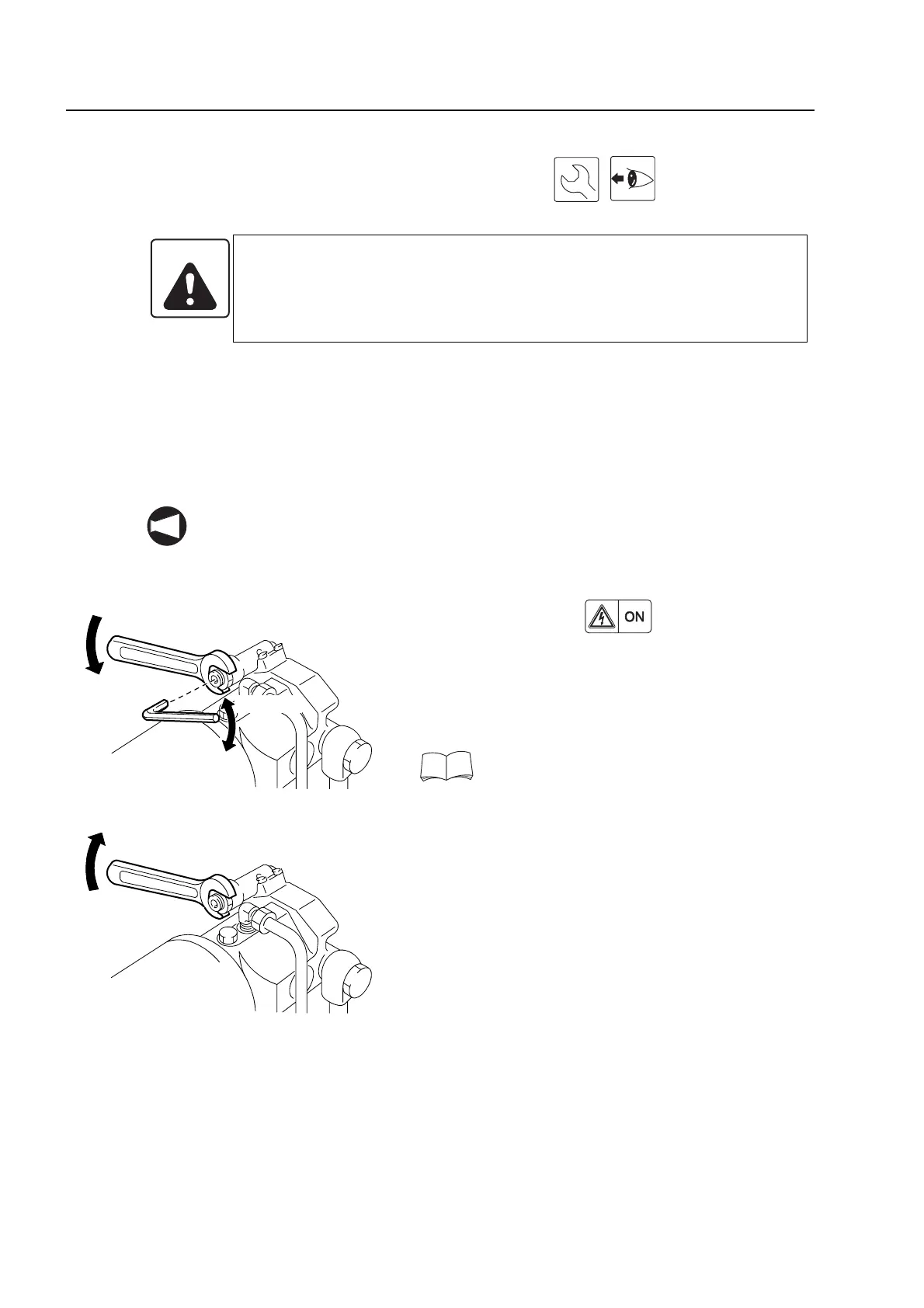

2) Loosen the lock nut of the main pressure adjusting

screw.

3) Turn the main pressure adjusting screw while

checking the pressure with the pressure gage.

For the setting pressure, refer to the

HYDRAULIC UNIT DIAGRAMS in the

DRAWINGS published separately.

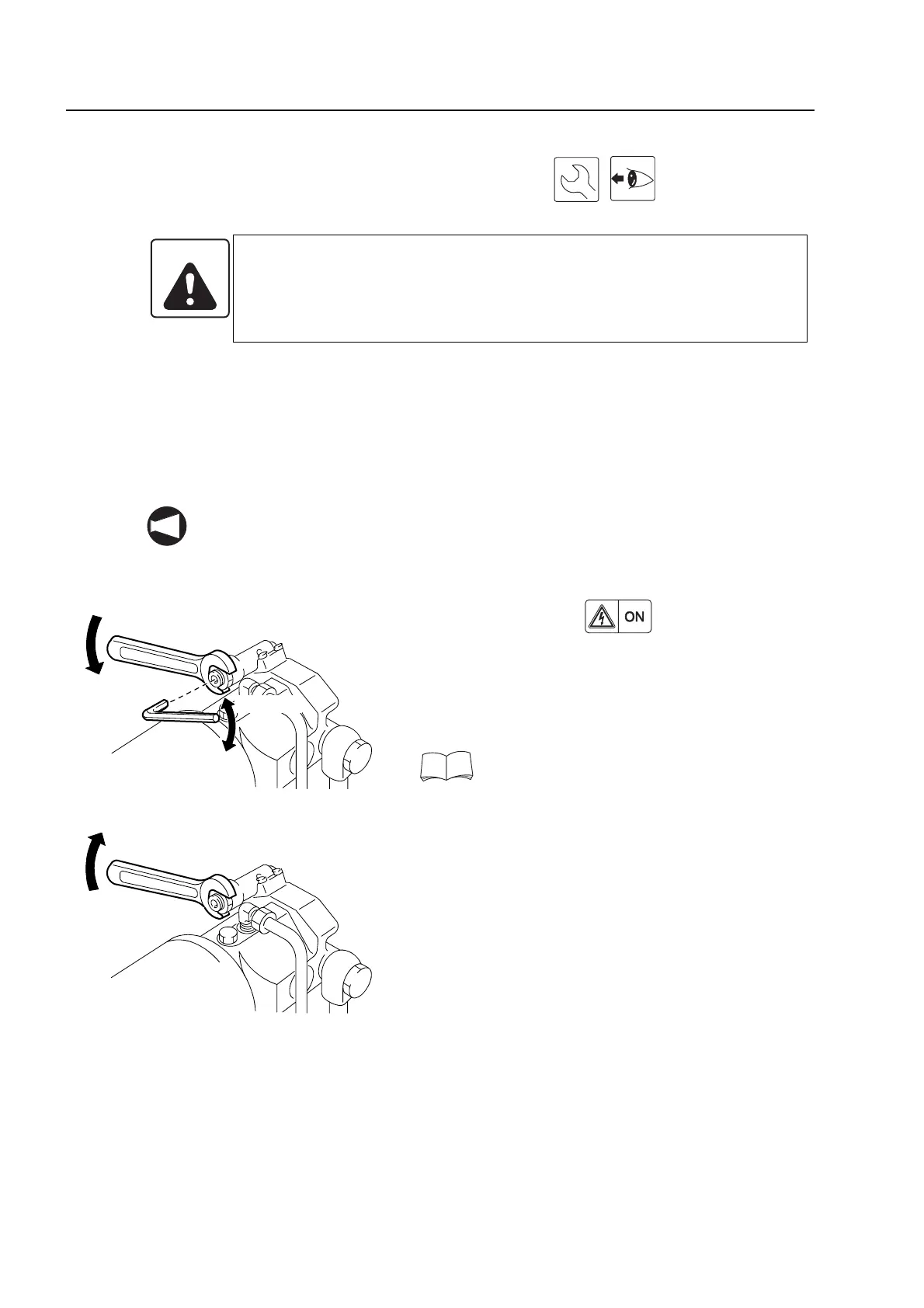

4) Tighten the lock nut after adjusting the main

pressure.

WARNING

Operating the machine while the pressure gages (hydraulic and air) do not

indicate the correct values could lead to serious injuries and damage to

the machine. If the gages do not indicate the correct values, adjust them

by following the procedure below.

NOTE

Decrease

Increase

Loading...

Loading...