C-4 OUTLINE OF SYSTEMS

4.2 Gripping Force

(1) Even if the same hydraulic pressure is applied to the chuck, the chuck gripping

force varies according to the manufacturer and type of the chuck and cylinder.

(2) The chuck gripping force varies according to the grease conditions, type of grease,

soft jaw height, etc.

(3) Obtain details of chuck gripping force from the chuck and cylinder manufacturers.

Use the chuck under the following conditions to obtain the workpiece gripping force specified in

the chuck instruction manual.

• Use standard soft jaws.

• Use grease containing molybdenum disulfide.

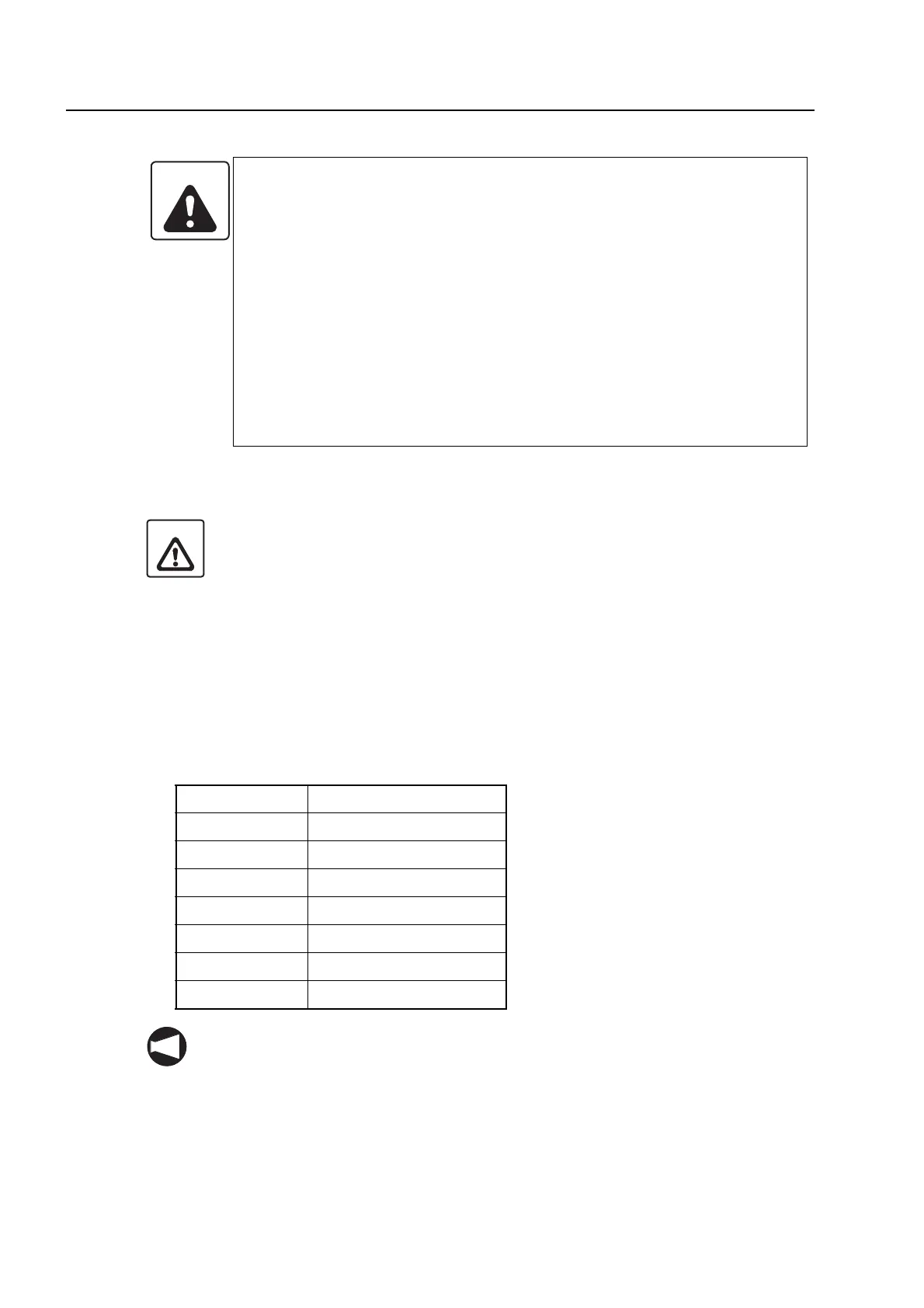

• Tighten the soft jaws at the specified torque:

The values given above are for reference only.

For the torque specification of the chuck actually used, refer to the instruction manual

supplied by the chuck manufacturer.

• The cylinder thrust must be lower than the maximum allowable thrust.

WARNING

(6) The chuck or fixture that holds the workpiece must be secured to the

spindle using the threaded holes in the spindle nose. Do not mount

another chuck or fixture in the chuck or fixture that is mounted

directly on the spindle. If a workpiece is held by a second chuck or

fixture mounted in this way, it will not be held securely when the

spindle rotates due to the centrifugal force acting on it, and the chuck

or fixture will fly out. This could cause serious injuries or damage to

the machine.

If it is necessary to mount a chuck or fixture in the chuck or a fixture

which is directly mounted to the spindle in order to hold a workpiece,

contact Mori Seiki or the chuck manufacturer for the measures that

should be taken.

Bolt Size Specified Torque

M6 12.7 N

•m (9.40 ft•lbf)

M8 38.2 N

•m (28.21 ft•lbf)

M10 72.6 N

•m (53.52 ft•lbf)

M12 106.9 N

•m (78.84 ft•lbf)

M14 170.6 N

•m (125.85 ft•lbf)

M16 250.1 N

•m (184.44 ft•lbf)

M20 402.1 N

•m (296.55 ft•lbf)

CAUTION

NOTE

Loading...

Loading...