C-6 OUTLINE OF SYSTEMS

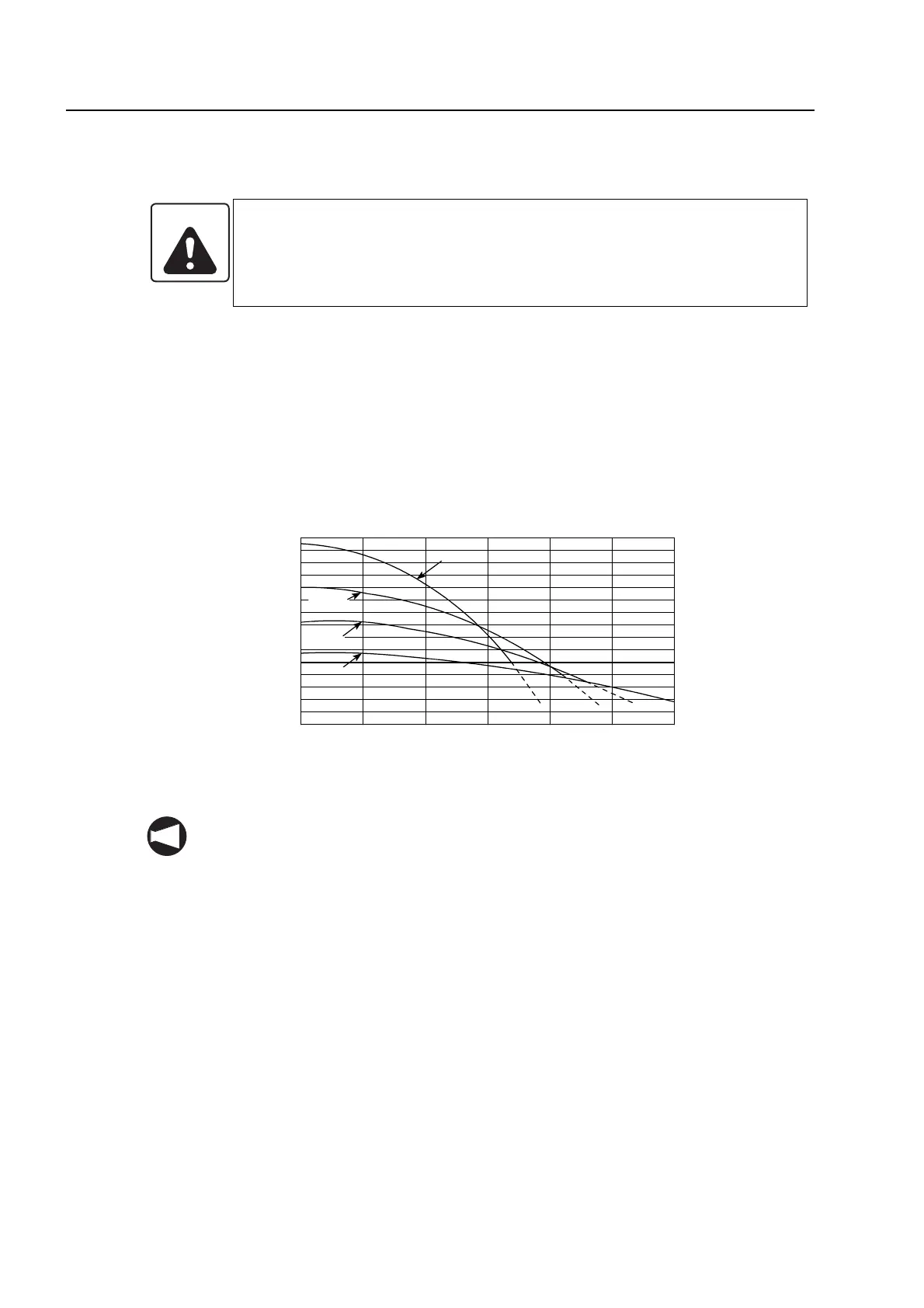

4.4 Relationship between Gripping Force and Spindle Speed

The curves in this diagram show how gripping force is reduced as spindle speed increases when

standard soft jaws are used. This relationship will vary considerably according to the jaw sizes,

shapes and mounting positions.

Therefore, gripping force must be measured with a gripping force meter if cutting is to be done at a

high spindle speed.

Example) Kitagawa hollow chuck

The values given above are for reference only.

For the relationship between the gripping force and the spindle speed for the chuck

actually used, refer to the instruction manual supplied by the chuck manufacturer.

WARNING

The chuck gripping force is reduced as spindle speed increases,

generating centrifugal force on jaws.

Heavy cutting at high spindle speeds might cause the workpiece to slip in

the chuck or fly out of the chuck.

B-212

B-210

B-208

B-206

147.1147.1

98.0

49.0

00 10001000 2000 5000 600040003000

Speed (min

−1

)

Total Gripping Force (kN (lbf))

NOTE

Loading...

Loading...