MACHINE PREPARATION and OPERATION (Cont.)

LASER SIGHT GUIDE SYSTEM

1 The laser sight system is intended as a guide only

and should not be used for accuracy of the cut.

2 Depress Laser power switch (Fig. 6)

3 Laser Beam follows the angle of the base plate.

4 Alight laser beam with your cut line.

5 After completing the cut depress the laser power

switch to disconnect power to laser.

ALIGNMENT TIPS FOR LASER SIGHT GUIDE

1 Find a square, at work piece of either steel or plywood

and place the work piece on a table. (Fig. 7)

2 Push the blade guard up and away from the blade.

3 Place the saw on the top of the work piece.

The blade should touch the edge of the work piece. (Fig. 7)

ADJUSTING FOR PARALLEL

Depress power laser power switch. If the laser line does not

line up with the edge of work piece then:

a. For small adjustments use a M2 hex key and loosen

or tighten the screw adjustment. (Fig. 8) to bring

the beam back to parallel.

b. For larger adjustments use a small at head screw

driver to the slot in the front of the light (Fig. 9)

to realign the beam. Then use the M2 hex key and

loosen or tighten the screw in order to do the nal

positioning. (Fig. 10)

c. The laser light and the 2 sight line markings, on the

base plate should now be in the same plane.

5

LASER RADIATION

Avoid direct eye contact

with light source.

Do not point laser at anyone.

Never look into the laser light.

Turning the laser o does not turn

power o to the saw.

READ AND SAVE ALL INSTRUCTIONS FOR FUTURE USE!

DANGER

Do not turn on saw

for this adjustment!

Serious injury could result.

Do not overturn the adjustment

screw on the front of the light.

You could damage threads or the

plastic housing for the laser.

CAUTION

(FIG. 6)

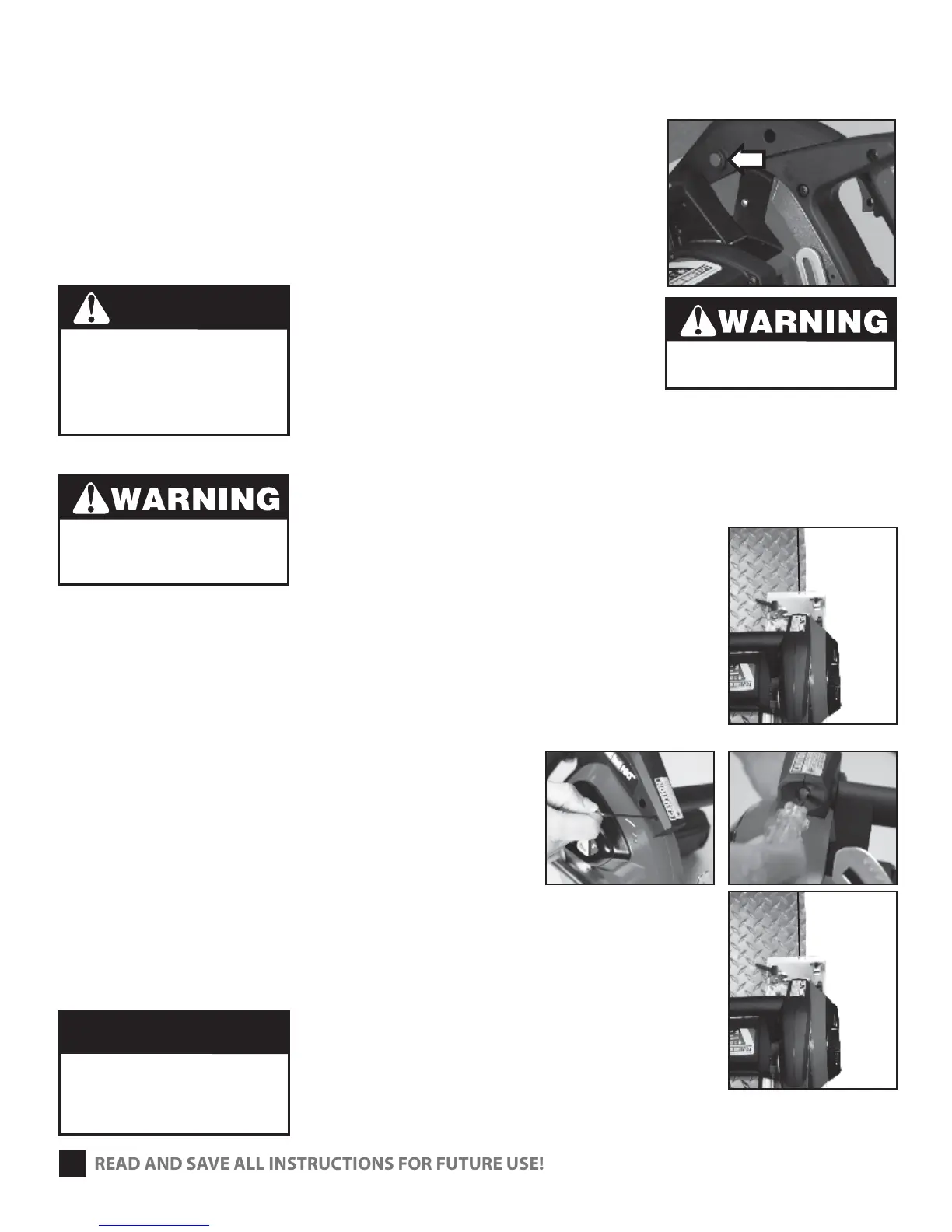

(FIG. 8)

(FIG. 9)

(FIG. 10)

(FIG. 7)

Loading...

Loading...