Page 11 mrcool.com

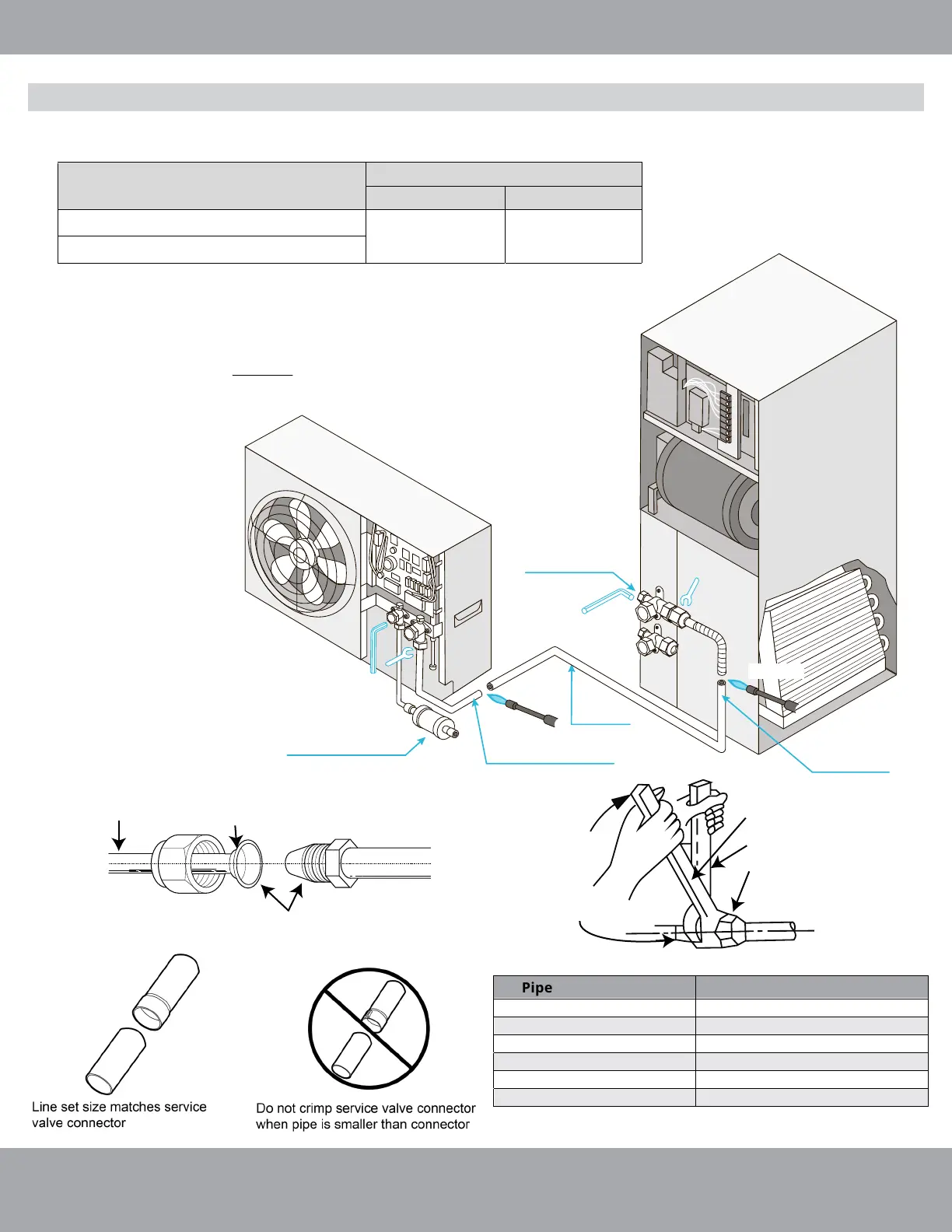

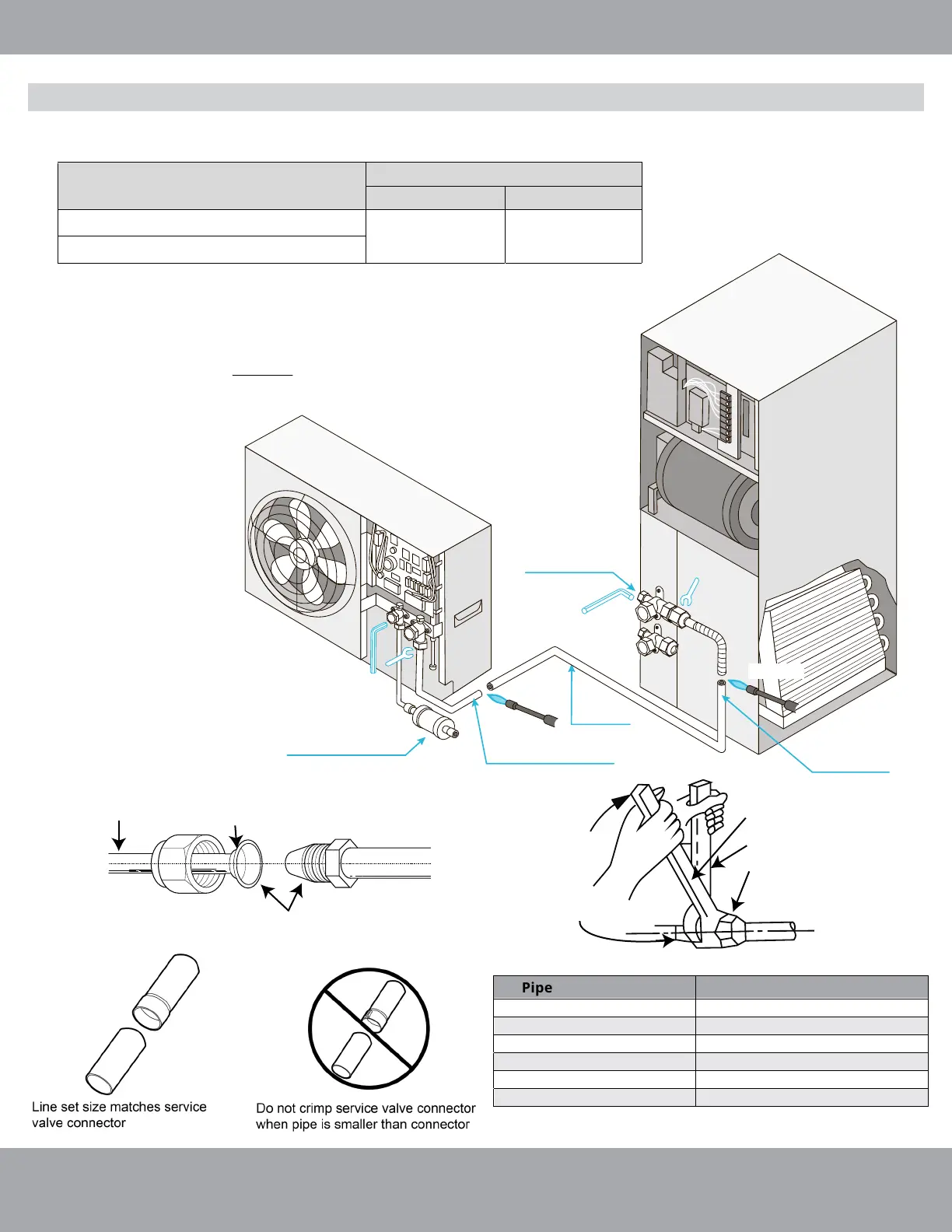

Unit Installation - OPTION 1: Conventional Weld / Flare Line Set

Conventional Line Set Installation

Specification of Connection Pipe

Piping Preparation

1.

WELD Type Complete Unit Replacement

All cut ends are to be round, burr free, and cleaned. Failure to follow this

practice increases the chances for refrigerant leakage. Line set size matches

service valve connection. DO NOT crimp service valve connector when pipe is

smaller than connector. See diagram below.

2. Screw Connection

Copper Piping

Oil Applied (to reduce

friction with the flare nut)

Oil Applied (improves

air-tight seal)

Fig. 2.5

Fig. 2.4

Fig. 2.3

Torque Wrench

Spanner

Piping Union

Flare Nut

Model

External diameter (inch)

MDUI18024E / MDUI18036E (2-3 ton)

Purge with

Nitrogen

Must open stop valves

after pulling vacuum

and before powering

on unit

Weld joint

Weld joint

Air Handler

MRCOOL Universal Series

DC Inverter

Open stop valves with allen

wrench only after nishing

lineset connections and before

powering on the unit

Must install lter

drier bi ow with this

installation type

Must Purge with Nitrogen

before brazing joints

Must Purge with

Nitrogen before

brazing joints

MDUI18048E / MDUI18060E (4-5 ton)

Loading...

Loading...