17 | Droit d’auteur Multi PSI. Toutes les informations contenues dans ce document sont sujettes à

modification sans préavis. Copyright Multi PSI. All information contained herein is subject to change

without notice.

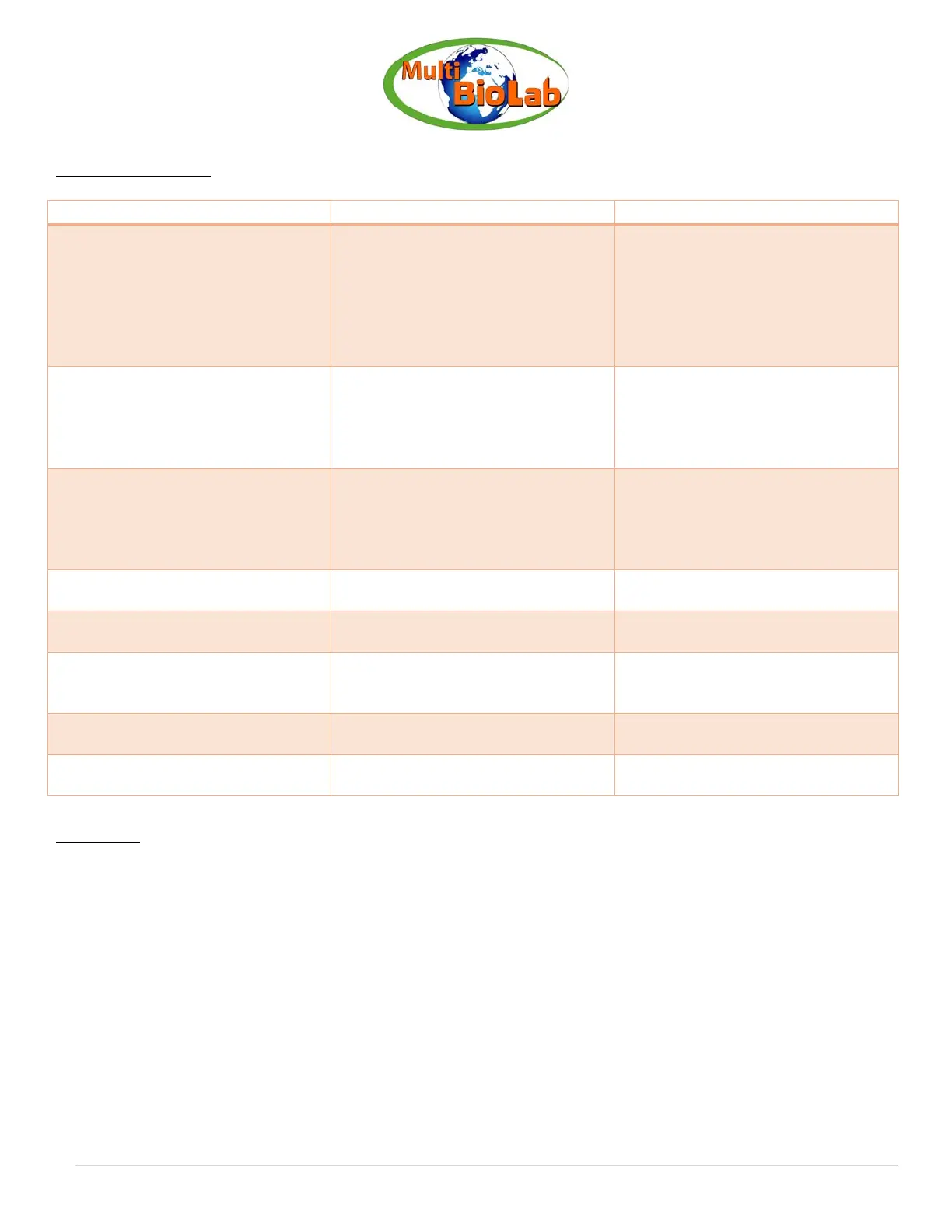

Troubleshooting

Problem Cause Solution

Little or no material flow 1. Nozzle clogged

2. Suction tube clogged

3. Material volume setting turn too

far to the right

4. Suction tube loose

5. Material is too thick

6. Container is loose

1. Clean

2. Clean

3. Turn to the left

4. Insert

5. Check viscosity

6. Tighten the container

Material leaking 1. Nozzle loose

2. Nozzle worn

3. Nozzle seal worn

4. Material build-up on spray pattern

dial and nozzle

1. Tighten

2. Replace

3. Replace

4. Clean

Atomization is too coarse 1. Viscosity of material too high

2. Matrial volume too large

3. Nozzle clogged

4. Too little pressure build-up in

container

1. Thin

2. Turn to the right

3. Clean

4. Tighten container

Spray jet pulsates 1. Material in container running out

2. Material is too thick

1. Refill

2. Check viscosity

Pattern runs or sags 1. Applying too much material 1. Adjust material flow or increase

movement of spray gun

Too much over-spray 1. Gun too far from spray object

2. Too much material applied

1. Reduce distance

2. Turn material volume setting to

right

Pattern is very light and splotchy 1. Moving the spray gun too fast 1. Adjust material flow or decrease

movement of spray gun

Large cloud of material 1. Gun too close to surface 1. Move gun away from surface and

reduce material flow

Warning

Keep your workplace clean and tidy, never use the tool in hazardous areas that contain flammable

liquids, gasses or dusts.

Only use paints, solvents or other materials with a flash point of 73ºF (22ºC) or highter..

Never point the spray gun at other person or animal. In the event of an injury, seek immediate medical

attention.

Always read the material manufacturer’s thinning instructions before use.

You must clean the spray gun thoroughly after each use.

Do not pull the power cord to move this tool.

Loading...

Loading...