Operating Manual

MSBA00049

Date: 21.03.2019

Rev.: 05

Page 8 of 14

Mütec Instruments GmbH Tel.: +49 (0) 4185-80 83-0 E-Mail: muetec@muetec.de

Bei den Kämpen 26 Fax: +49 (0) 4185-80 83-80 Web: www.muetec.de

D-21220 Seevetal-Ramelsloh

6 Mounting Instructions

6.1 Selection of the mounting position

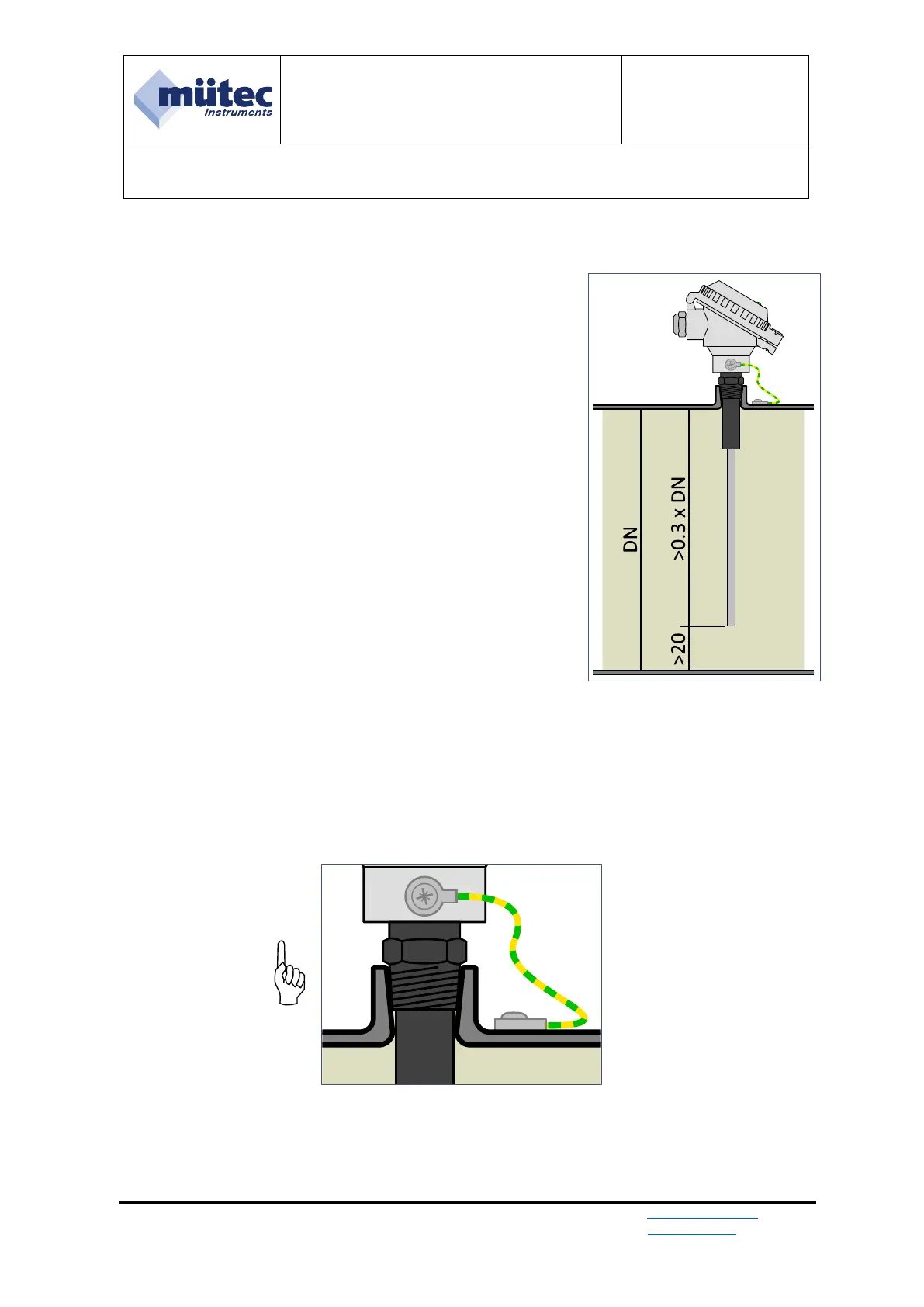

The inlet and outflow zone for FS750E should not be

less than 3 times the nominal diameter.

After fixing the threaded sleeve in a 90° angle to the

tube axis, the mounted weld must close the gap

between the sleeve and the pipe wall reliably.

The quality of the weld can be tested with a

subsequent pressure test. The drilling of the tube wall

for the required measurement window is performed

with an 18 mm drill bit. Therefor the previously welded

sleeve serves as a drilling template. After drilling, the

borehole on the inner pipe wall needs to be trimmed

as much as possible to ensure that material deposits

cannot take place.

6.2 Sensor Mounting

For mounting sleeve need to be threaded on the tube

in a 90° angle to the tube axis

The length of the sensor rod should be at least 1/3 of

the inner diameter of the pipe. The sensor rod must

not come in contact with the opposite wall or with

other metallic parts. Therefore it is recommended to

keep a minimum distance of 20mm between the

opposite wall and the end of the sensor rod.

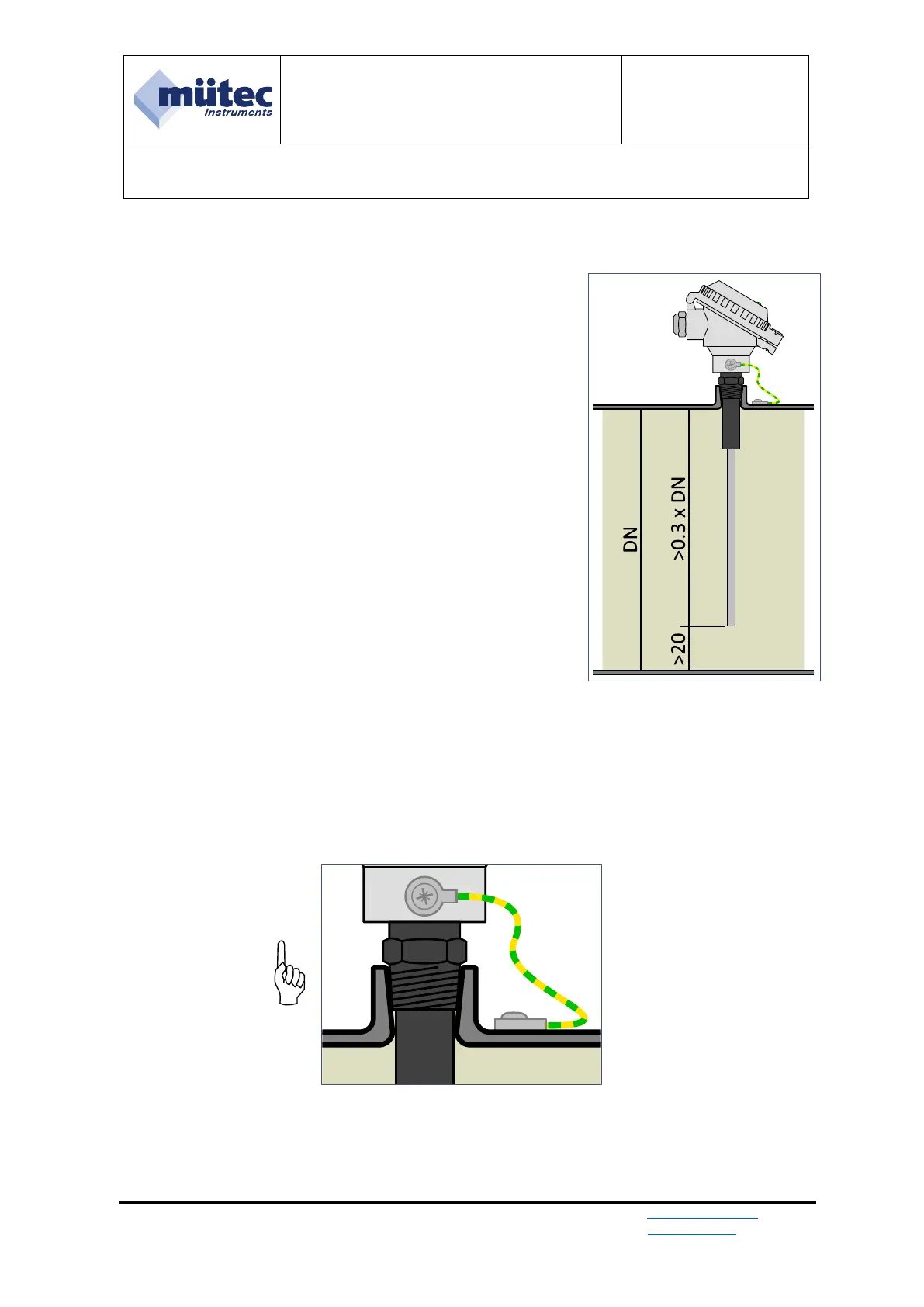

For proper device operation it is mandatory, to establish the earthing

connection between the sensor enclosure and the installation location (pipe).

Figure 2a: Sensor mounting

Figure 2b – Earthing connection

Loading...

Loading...