2202MYJE-MY-C8-N_2018.02.

Chapter 2 Compressor Specifications and Structure

Compound 2-stage Screw Compressor 3225**C 2.1 Overview of MYCOM 3225**C

2-1

Chapter 2 Compressor Specifications and Structure

2.1 Overview of the 3225**C

The 2-stage compression system, which has hitherto required two units of standard-type screw

compressor for its embodiment, can now be realized by a single unit of compound 2-stage screw

compressor.

Generally, screw compressors use oil injection to keep discharge temperature at a low level during

operation without loss of volumetric efficiency even at high compression ratios. It can, therefore, be

operated with a single-stage compression system even at evaporative temperatures near -40°C.

However, for normal use at low temperatures, a 2-stage compression system is applied in order to

improve kW/RT (ratio of power consumption versus cooling ability). If the 2-stage compression system

is configured with standard-type screw compressors, at least two screw compressor units need to be

installed, one on the high-stage and the other on the low-stage, which inevitably requires double

installation of the entire system including machinery, motors, utilities, etc.

This 2-stage screw compressor is produced to solve this problem. It is a single unit that has two

single-stage compressor units combined into one.

The 3225**C model has a capacity control mechanism for startup load reduction on the high-stage, and

a capacity control mechanism for coping with load change on the low-stage.

In addition, there are four rotor lengths for the low-stage and three rotor lengths for the high-stage.

Moreover, customer is able to select each low-stage and high-stage volume ratio from two

specifications. Employing these combinations of each specification, 3225**C is providing a high

versatility that can satisfy a wide range of operation conditions required by different applications at the

load side. Therefore, the 3225**C models are the long-selling products which last to

more than 30 years since the developed in 1982 as the large sized compound 2-stage screw

compressor.

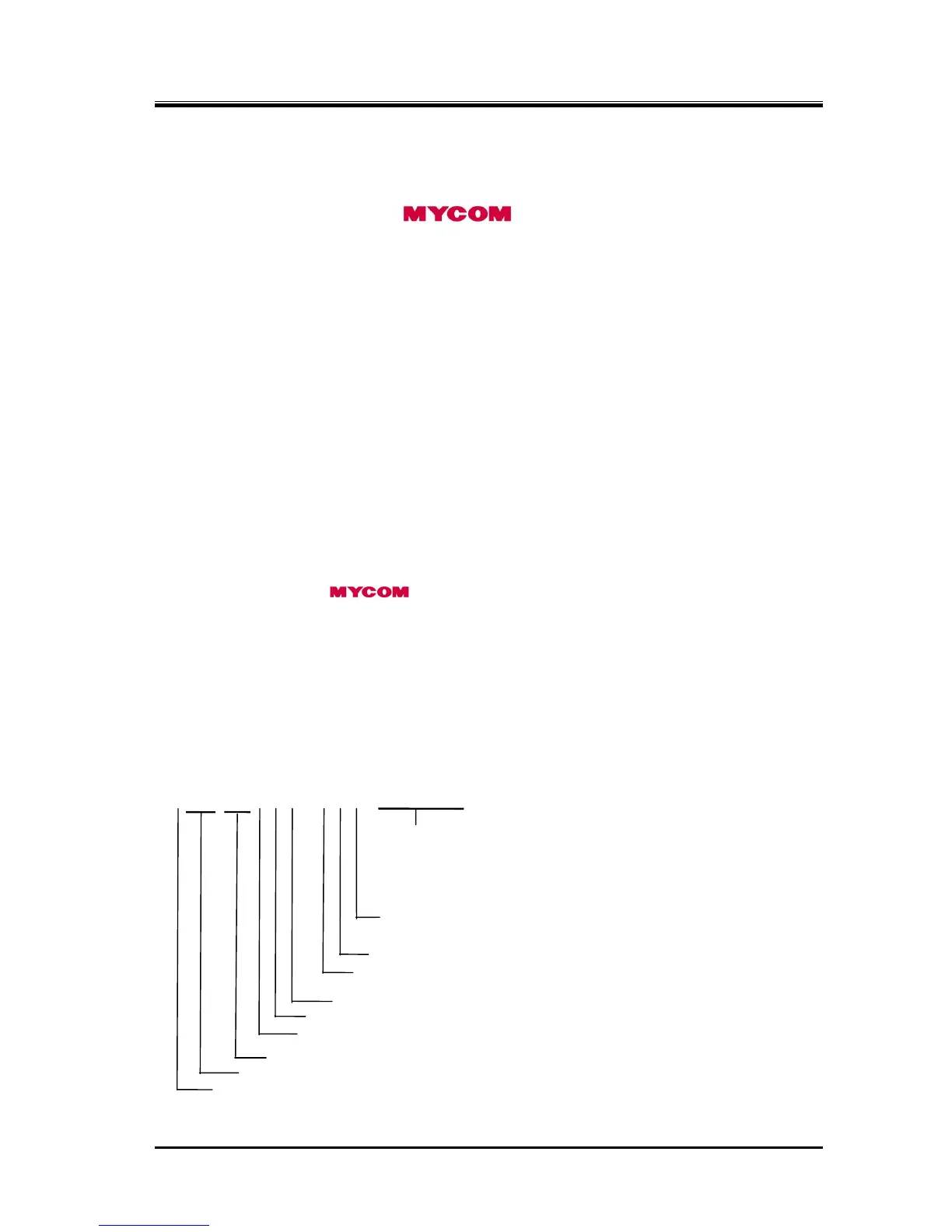

2.2 Model Designation of the Compressor

This manual describes 3225**C-*B*-51 and 3225**C-*B*-61 models.

The meaning of the type designation, which is engraved on the MODEL column of the compressor

nameplate, is as follows.

*3225**C-*B*-51/61

5: Power frequency (6: 60Hz)

1: Indicates that it is a motor directly connected type.

* Unless specifically specified, machines manufactured in

September, 2010 or after do not have this indication engraved

on their nameplate.

Vi (volume ratio) specified for the high-stage discharge port,

standard value of which is L or M

Means a booster (low-stage machine)

Vi (volume ratio) specified for the low-stage discharge port, standard

value of which is L or M

Stands for Compound (compound 2-stage machine)

Specifications of high-stage rotor length, which is L, M or S

Specifications of low-stage rotor length, which is LL, L, M or S

High-stage rotor diameter of 250

Low-stage rotor diameter of 320

Indicates working fluid

(Example: N = Ammonia, F= Fluorocarbon, P = Propane, HE = Helium)

Loading...

Loading...