2203M4JE-MY-iS2-N_2017.04.

Chapter 5 Maintenance and Inspection

Screw Compressor i-series

5.4 Disassembly and Inspection

5-15

5.4.3 Balance Piston

5.4.3.1 Disassembly

The balance piston sleeve [33] and the balance piston [30] can

be removed just by removing the snap ring [32].

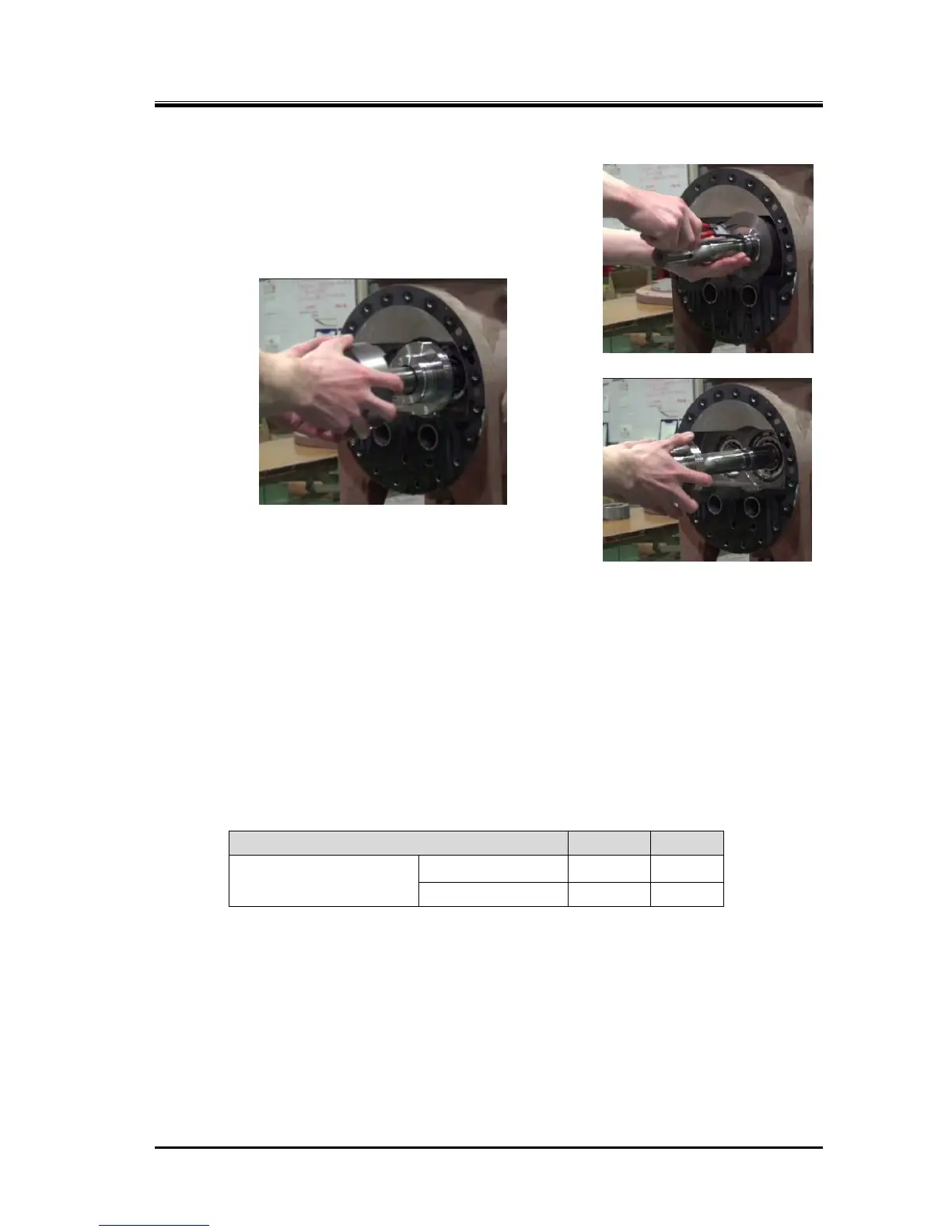

Photo 008 Removing the Snap Ring

Photo 009 Removing the Balance Piston Sleeve

Photo 010

Removing the Balance Piston

5.4.3.2 Inspection

a) If there are defects such as extreme wear, galling or chipping on the outer circumference of the

balance piston or on the inner circumference of the balance piston sleeve, replace the defective

component with a new one.

b) Measure the large and small outer diameters of the balance piston at four locations each.

If either of the maximum values indicates that the part is worn down to or beyond the replacement

criteria shown in Table 5-9, the part should be replaced with a new one.

When replacing with new ones replace the balance piston and balance piston sleeve in a set.

Table 5-9 Balance Piston Replacement Criteria

5.4.4 End Cover

a) Remove two hexagon socket head cap screws (i125* [2-2], i160* [2]) symmetrically, and insert stud

bolts. In the case of i160* , attach lifting tools to the end cover before proceeding to the next step.

b) Pull out remaining bolts, and remove the end cover [22]. At this moment, lubricating oil remaining

inside the end cover will flow out. Prepare a container to catch oil.

Balance Piston diameter

(mm)

Large diameter 112.89 134.85

Loading...

Loading...