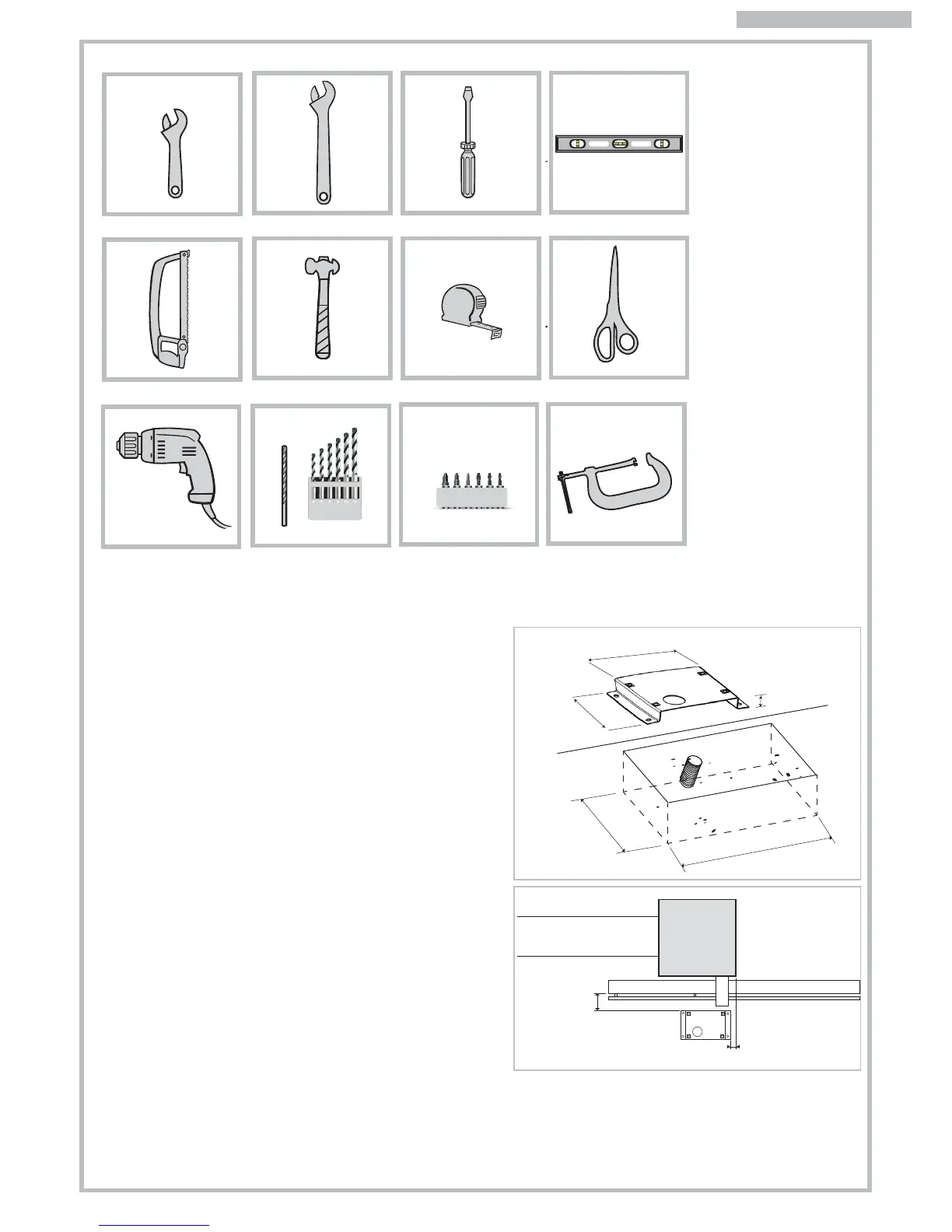

Fig. 2

55/60 mm

20/30 mm

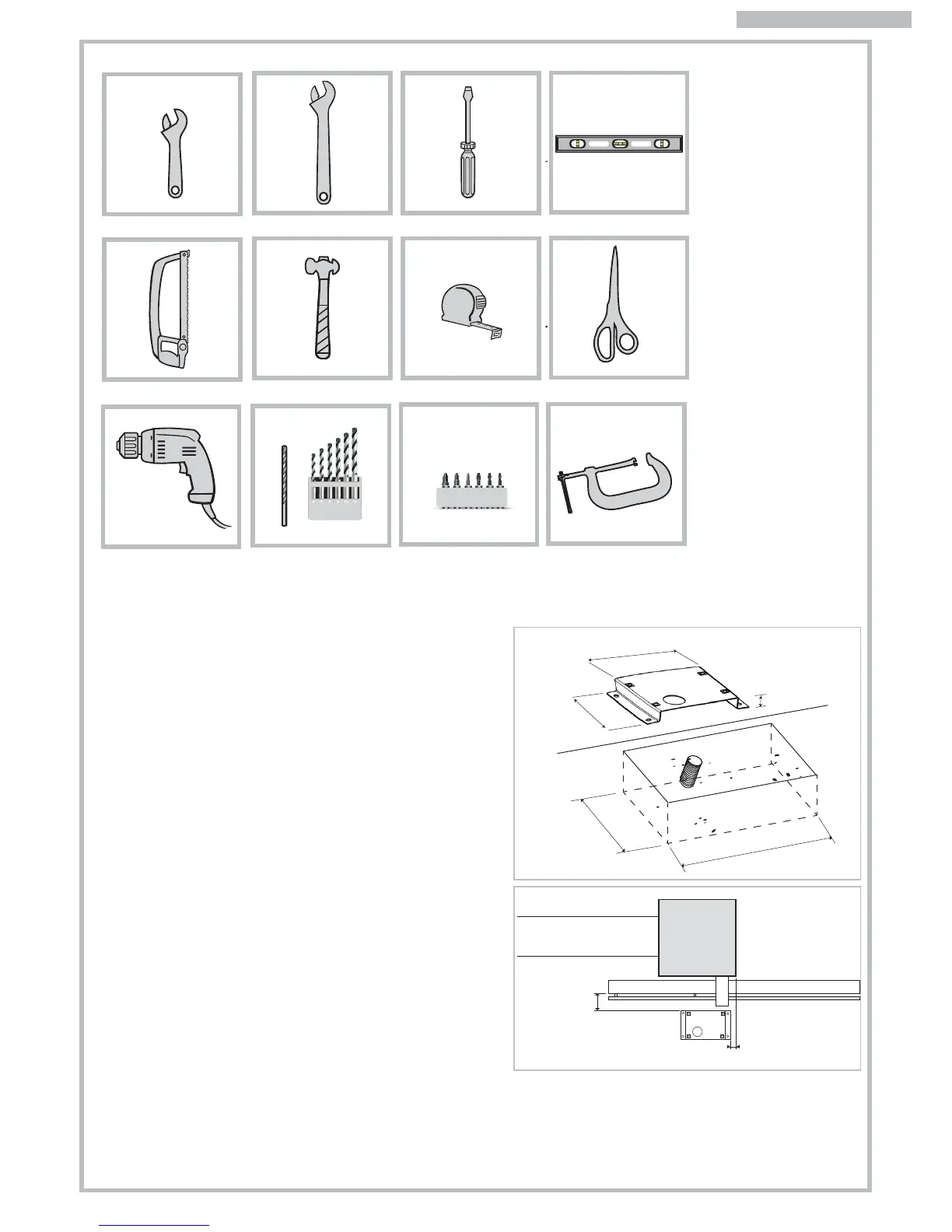

Fig. 3

260+ 50 mm

177+ 50 mm

260

177

32

4

3.4 PRELIMINARY INSTALLATION WORK

AND MASONRY FOR ANCHOR PLATE

Identify approximately the place of each component and

proceed as follows:

a) Dig the foundation pit for the gear motor whilst considering

the anchor plate dimensions. Give an extra 5cm area extra

on each side. Pay attention to measurements shown in Fig.2.

b) Provide one or more ducts for the electrical cables so that

they can easily go through the purpose fabricated hole in

the gear motors anchor plate. Pay attention to the plate’s

orientation: hole for cables routing on the side opposite the

gate (see Fig. 2).

c) Set concrete into the pit. Ensure this is level and smooth out

the surface. Wait for the concrete to get solidify (this may

take a few days).

d) Insert the cables ducting to the hole in the anchor plate and

fix the plate to the concrete using suitable plugs.

e) Cut the cable ducts about 3cm above the anchor plate

level and route the cables for accessories and electrical

mains wiring as shown in Fig. 3 diagram. Ensure the cables

are at least 30-50cm out from the ducting to allow easy

wiring to the control panel.

3.3 TOOLS NEEDED

ENGLISH

Loading...

Loading...