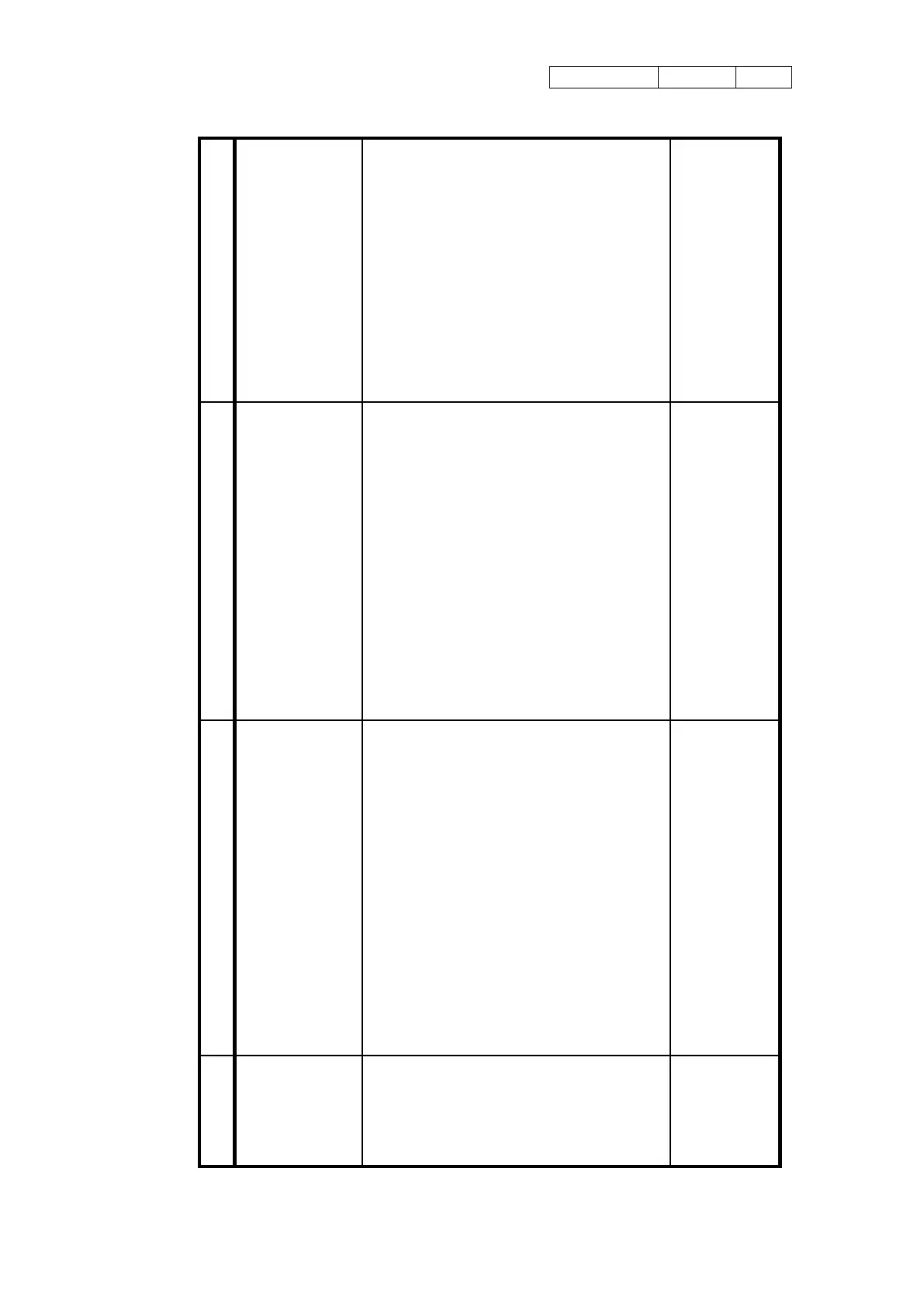

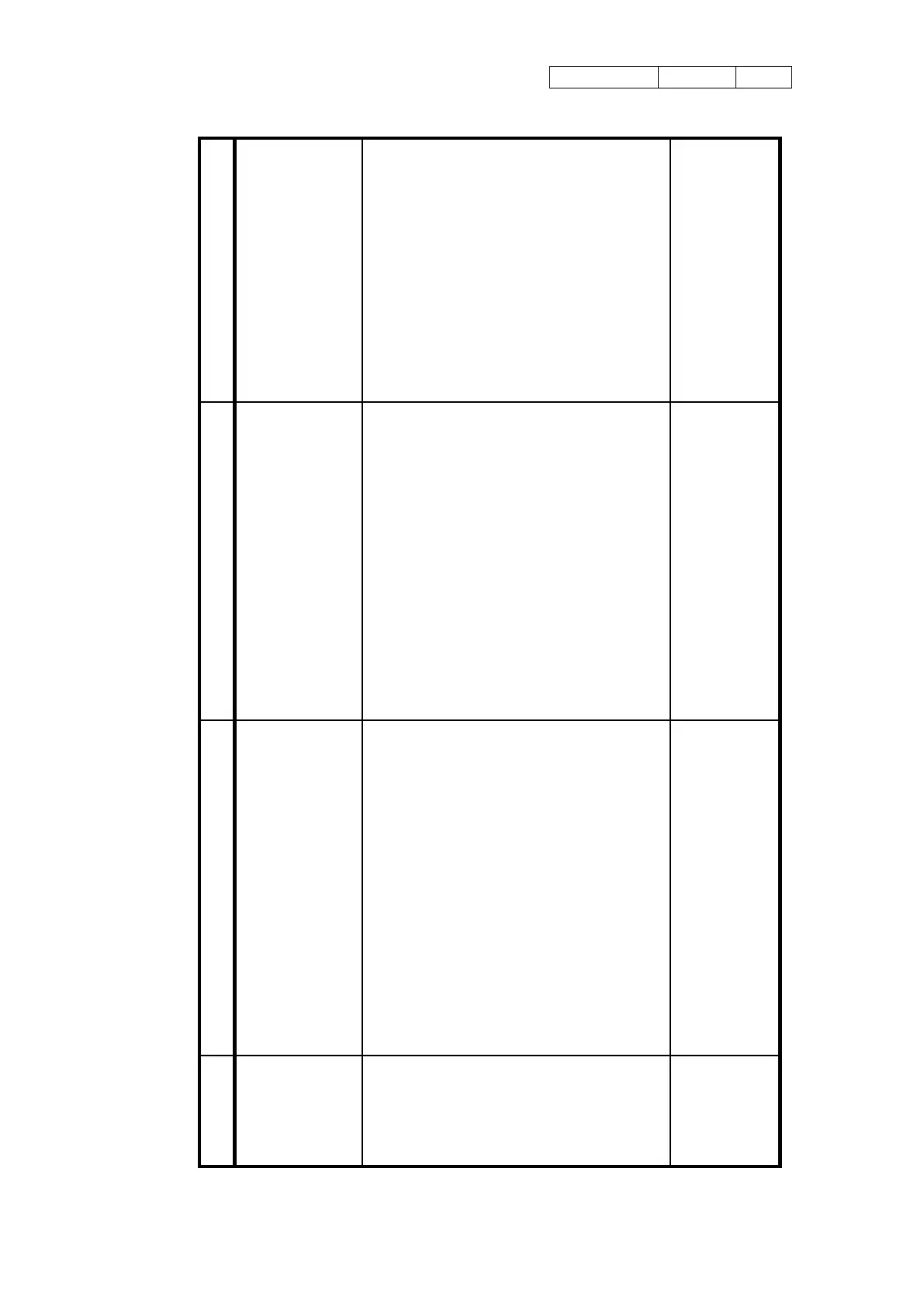

TY1-3A 17/18

Countermeasures

1. Provide the pipe with a filter.

2. Open the valve.

1. If the ambient temperature is too

high, re-install the pressure gauge

in a different position. If process

fluid is hot, use a pipe siphon, etc.

to lower the.

2. Re-install the pressure gauge in a

different position.

3. When using a dampener.

1. Use a thicker pipe.

2. Adjust the restrictions properly.

Possible causes

1. Pressure is zeroed. (Pipe is clogged with

foreign matters contained in fluid.)

2. The valve is closed.

1. The operating temperature range is

exceeded.

2. Wear of the movement due to vibrations.

3. Wear of the movement due to fluctuating

pressure.

1. Process fluid is too viscose. Or the pipe is

too thin for the process fluid viscosity.

2. Dampener is stopped down excessively.

Check points

1. Check if pressure is applied to (fluid flows

through ) the pressure gauge.

2. Check if the valve of the pressure gauge is

open.

1. Check if the fluid and ambient temperatures

are within the operating temperature range

of the pressure gauge.

2. Check if excessive vibrations are not applied

to the pressure gauge.

3.

Check if excessive fluctuating pressure is not

applied to the pressure gauge.

1. Viscosity of process fluid and pipe thickness.

2. Degree of stopping down the dampener.

Troubles

not move.

does not

indicate

pressure.

response.

Table.10 (1/2) Trouble Shooting

Loading...

Loading...