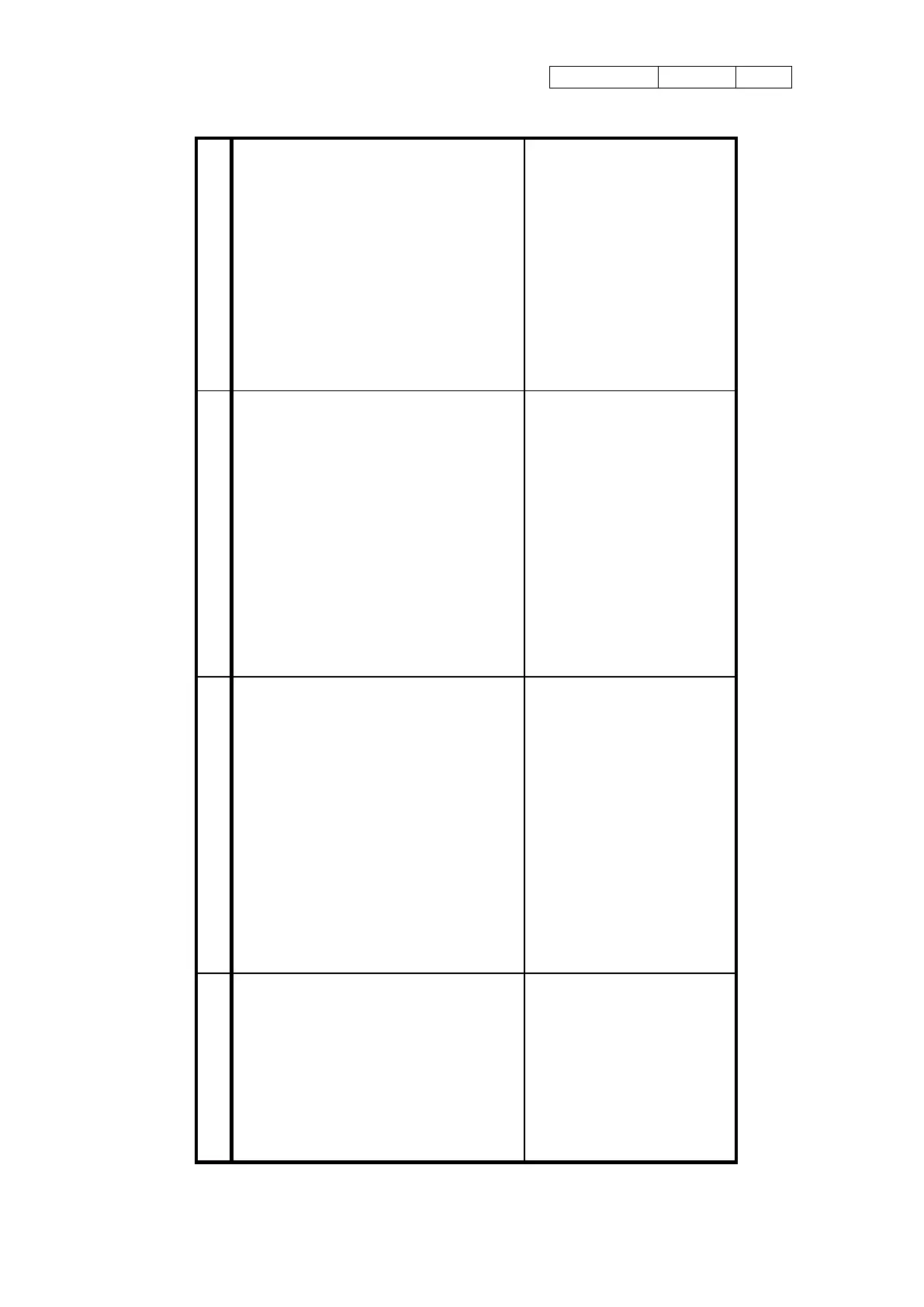

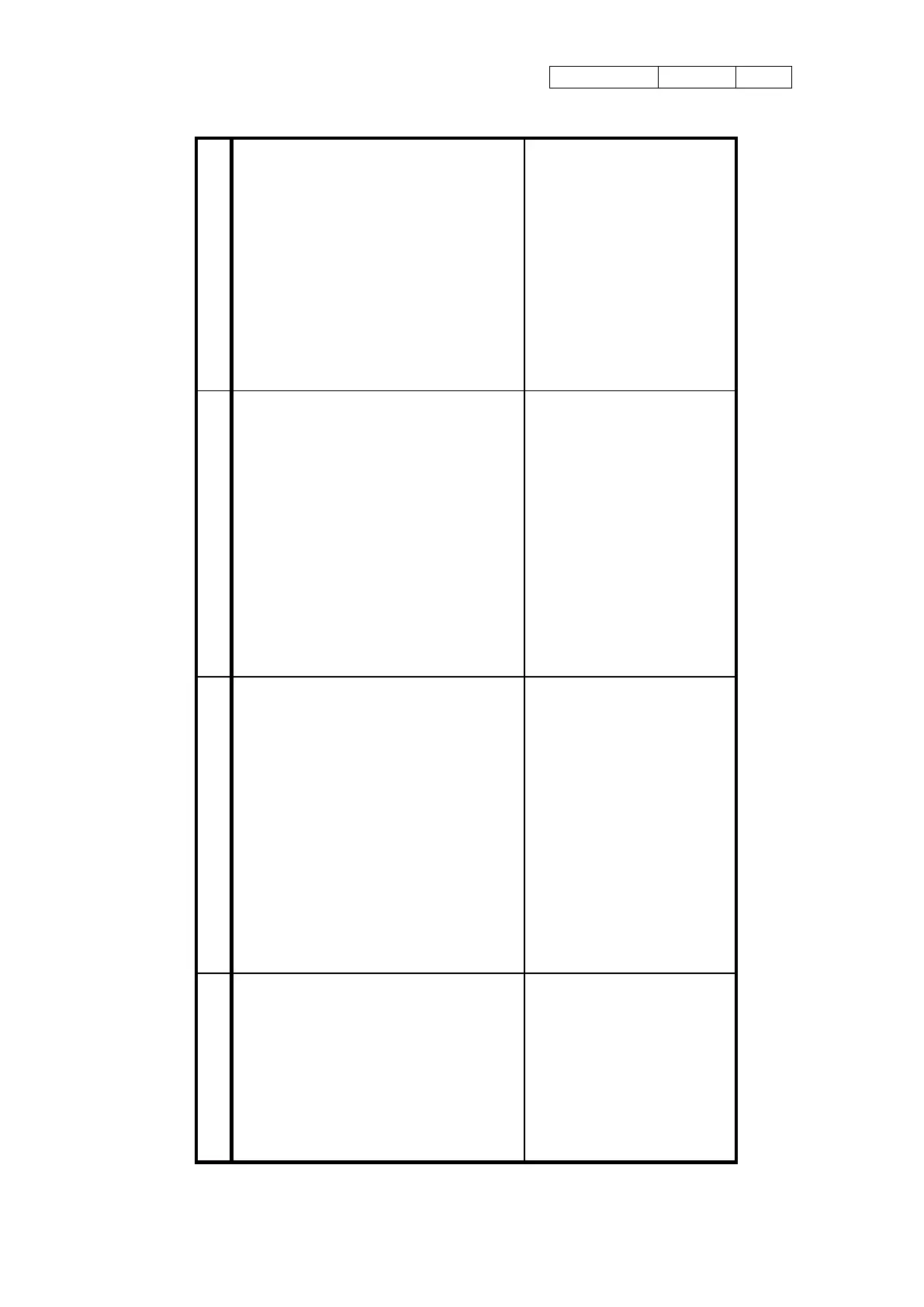

TY1-3A 18/18

Countermeasures

1. Use a pressure gauge of higher

range.

Take an overpressure prevention

countermeasure.

2. Provide the pipe with a filter.

3. Re-install the pressure gauge in

a different position.

When using a dampener.

1. Use a pressure gauge of higher

range.

Take an overpressure prevention

countermeasure.

2. Be careful not to apply impacts

to the gauge.

Possible causes

1. Bourdon tube is deformed by an

excessive pressure.

2. Clogging with foreign matters

contained in fluid.

3. Wear of the movement due to

vibrations or fluctuating pressure.

1. Bourdon tube is deformed by an

excessive pressure.

2. Shift of the pointer or deformation of

the Bourdon tube due to impacts.

Check points

1. Check whether or not an excessive

pressure is applied.

2. Check whether or not the throttle is

clogged.

3. Check whether or not excessive

vibrations or fluctuating pressure are

applied to the pressure gauge.

1. Check whether or not an excessive

pressure is not applied.

2. Check whether or not the pressure

gauge is dropped or impacts are

applied to it.

Troubles

Pointer does not read zero

piping.

Table.10 (2/2) Trouble Shooting

Loading...

Loading...