3/05 IOM-FPTU

Nailor Industries Inc. reserves the right to change any information concerning product or specification without notice or obligation.

Page 3 of 6

If repair or replacement is required:

Disconnect all power before servicing. Motor and fan should be

removed as an assembly. Remove the four hex nuts from the

mounting lugs holding the fan assembly to the discharge panel, and

remove the assembly through any convenient access panel. Do not

allow assembly to hang from wiring. If removing motor from blower,

first loosen the set screw holding the blower wheel to the motor

shaft. Remove the three screws holding the motor to the fan

housing, and slide motor and fan housing apart.

To put the assembly back together, reverse the procedure. Be sure

to align the blower set screw with the flat section of motor shaft.

Note: Over-tightening motor mounting screws may crush

isolation bushing, causing excessive fan noise.

Primary Air Damper Replacement

Nailor’s primary air valve assembly is not repairable. The entire

assembly should be replaced if it is damaged.

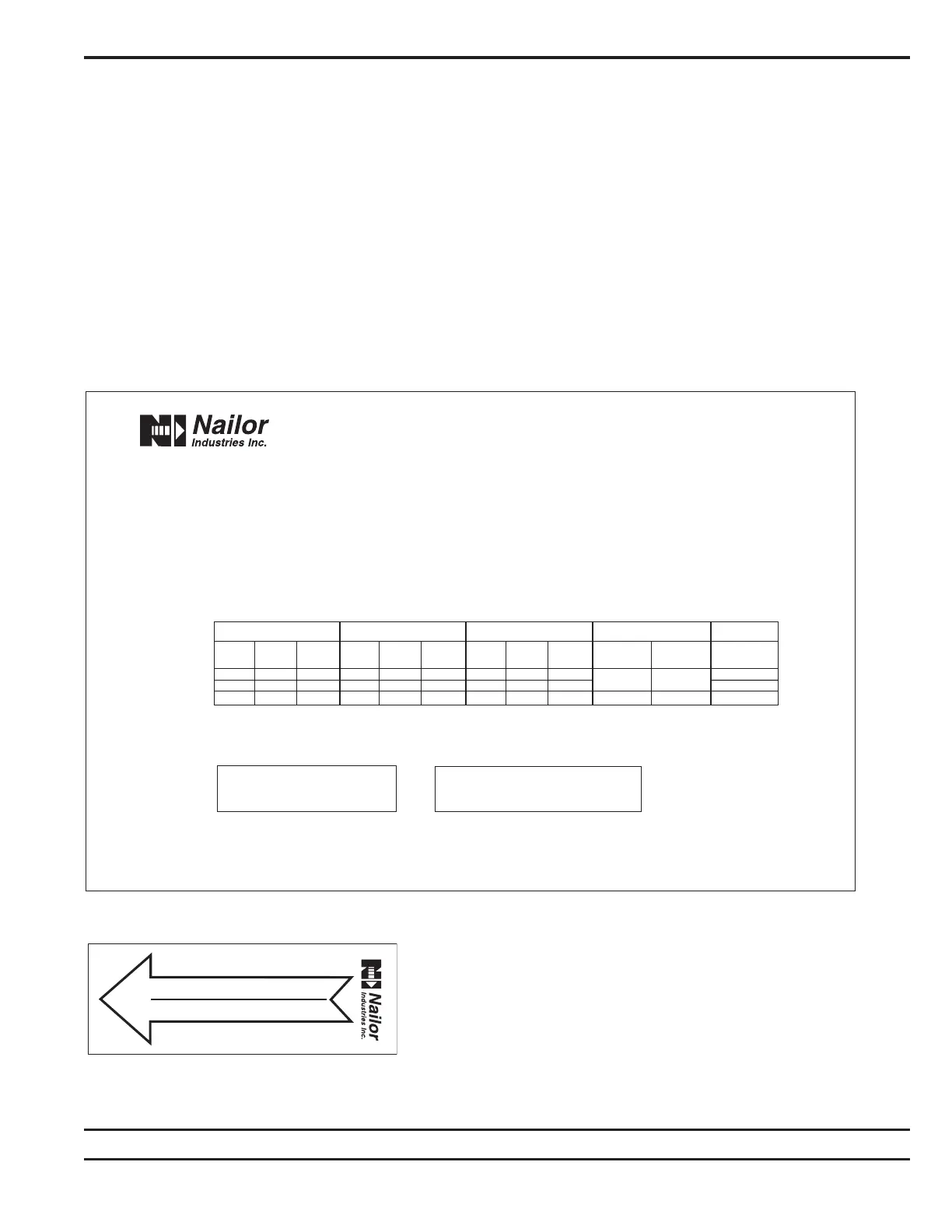

Labels

Each fan-powered unit is shipped with a nameplate label affixed to

the control casing. Principle nameplate data on the label typically

include Order-Serial number, Model number, Unit size, Motor

horsepower, Amperage, MOP, Heater (if present) data, Supply

Voltage, and Airflows. Also provided are calibration, airflow, as well

as other labels as necessary. We suggest that you read all labels

before beginning installation. If you have any questions, please

contact your local Nailor Representative. Their phone numbers can

be found on our website at www.nailor.com.

Nameplate Label

FAN POWERED

(UNITE TERMINALE @

TERMINAL UNIT

VENTILATEUR INTEGRÉ)

DATE (DATE) : 15-Apr-2002 SERIAL NO. (NO. DE SÉRIE) : 155258-10

MODEL (MODÈLE) : D35SE TAG NO. (NO. DÈTIQUETTE) :42

UNIT SIZE-INLET SIZE : 3-8 VOLTAGE (VOLTAGE) : 480

(DIAMETRE D'ENTRÉE) PHASE (PHASE) :3

CONTROL VOLTAGE : 24 STAGES (ÉTAPES) :2

(VOLTAGE DE CONTRÔLE) HZ. (HZ) : 50/60

CONTROL SEQUENCE : DF MOTOR HP (MOTEUR HP) : 1/4

(SEQUENCE DE CONTRÔLE) MOTOR VOLTAGE : 227

VOLT AMP (VOLT-AMPÈRE) :50 (VOLTAGE DU MOTEUR)

HOT WATER COIL ROWS : N/A MOTOR AMP : 1.8

(NOMBRE DE RANGÉES SERPENTIN EAUCAUDE) (AMPERAGE DU MOTEUR)

KW/HP AMPS AMPACITY MAX. OVERCURRENT PROTECTION MOTOR FUSE SIZE

(AMPÈRES) (AMPACITÉE) (RESISTANCE DES FUSIBLE MAX.) (MOTEUR FUSIBLE)

TOTAL EACH CIR. EACH STG. TOTAL EACH CIR. EACH STG. TOTAL EACH CIR. EACH STG. TOTAL EACH CIR.

(TOTALE) (CHAQUE (CHAQUE (TOTALE) (CHAQUE (CHAQUE (TOTALE) (CHAQUE (CHAQUE (TOTALE) (CHAQUE

CIRCUIT) ÉTAPE) CIRCUIT) ÉTAPE) CIRCUIT) ÉTAPE) CIRCUIT)

HEATER (CHAUFFAGE)

6.0 6.0 3.0 7.2 7.2 3.6 9.0 9.0 4.5

15 15

10

MOTOR (MOTEUR)

1/4 1.8 2.3 3.0

TOTAL (TOTALE)

9.0 11.3

EACH ELEMENT RATED @ 2.0 KW @ 277 VAC. AWG. MIN WIRE SIZE (MIN DIAMETRE DE FIL) : 14

(CHAQUE ELEMENT CLASSIFIER A) MIN. HEATING CFM (MIN. PCM) : 420

USE WIRE SUITABLE FOR AT LEAST 75

o

C UTILISER UN FIL METALIQUE QUI CONVIENT AU MOIN 75

o

C

L1 IS COLOR CODED BLACK , L2 IS BLUE, L3 IS RED L1 EST COLORÉ NOIRE, L2 EST BLUE , L3 EST ROUGE,

CONTROL WIRES CODED AS MARKED LES FILS DE CONTRÔLE SON INDENTIFIÉE COMME MARQUE,

USE COPPER CONDUCTORS ONLY. UTILISÉ DES CONDUCTEURS DE CUIVRE SEULEMENT.

USE CLASS K, RK1, A2D OR A6D FUSE OR HACR BREAKERS. UTILISÉ DES FUSIBLES CLASS K, RK1, A2D, OU A6D OU HACR DISJONCTEURS.

PRIMARY CFM (MAX/MIN) : 890/360 PRIMARY L/S (MAX/MIN) : 420/170

FAN CFM : 890<None> FAN L/S : 420

Airflow Direction (affixed to inlet collar)

Loading...

Loading...