26 About the Boiler

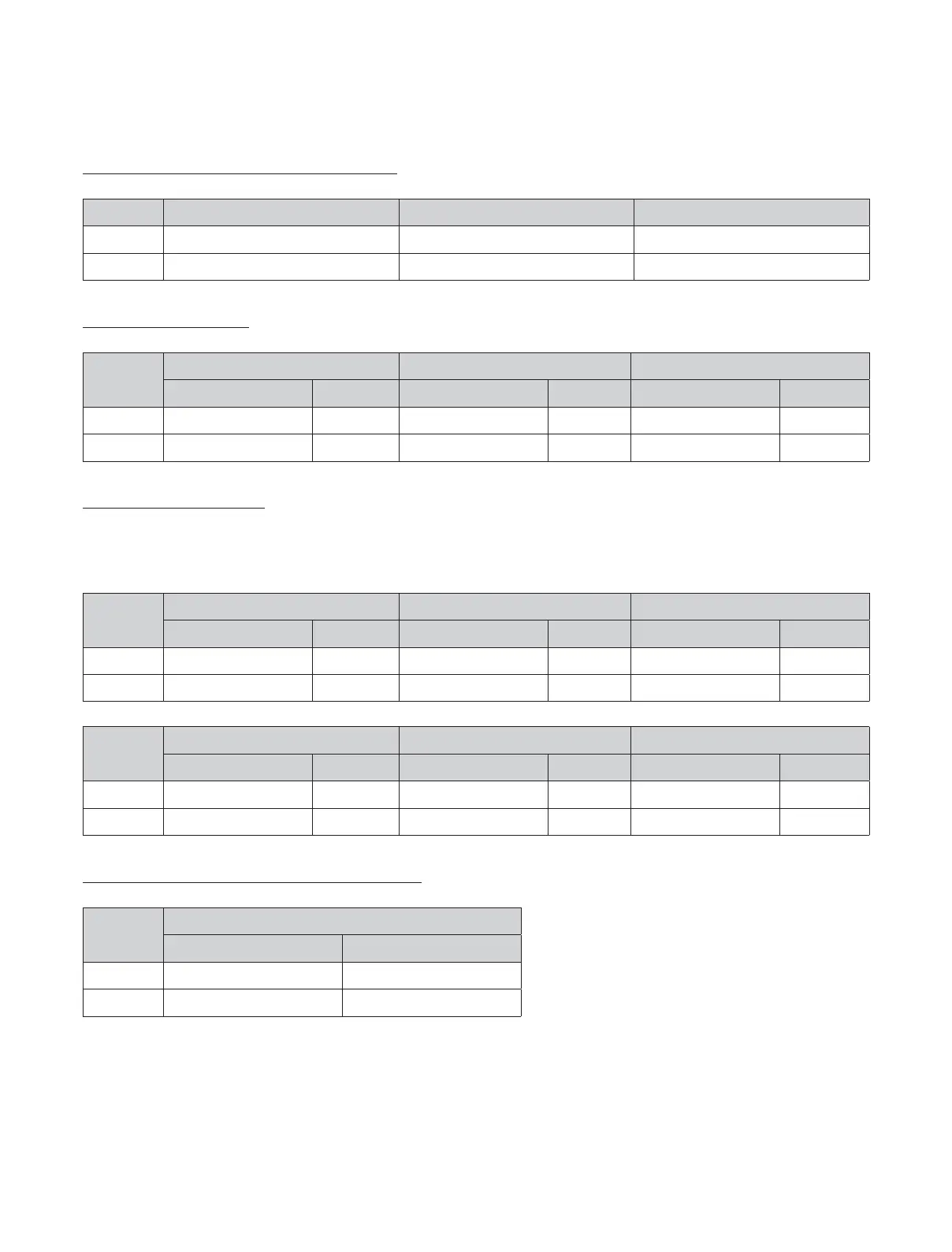

Maximum and Minimum Flow Rates through the Boiler

Model Minimum Pipe Diameter Maximum Flow (GPM) Minimum Flow (GPM)

NFB-301C 1

1

/

4

"32 10

NFB-399C 1

1

/

2

"42 12

Temperature Rise Conditions

Model

20°F T @ 100% water 25°F T @ 100% water 35°F T @ 100% water

Flow Rate (GPM) Head (Ft) Flow Rate (GPM) Head (Ft) Flow Rate (GPM) Head (Ft)

NFB-301C 29 10.5 24 7.4 17 4.0

NFB-399C 39 4.3 31 3.0 22 1.8

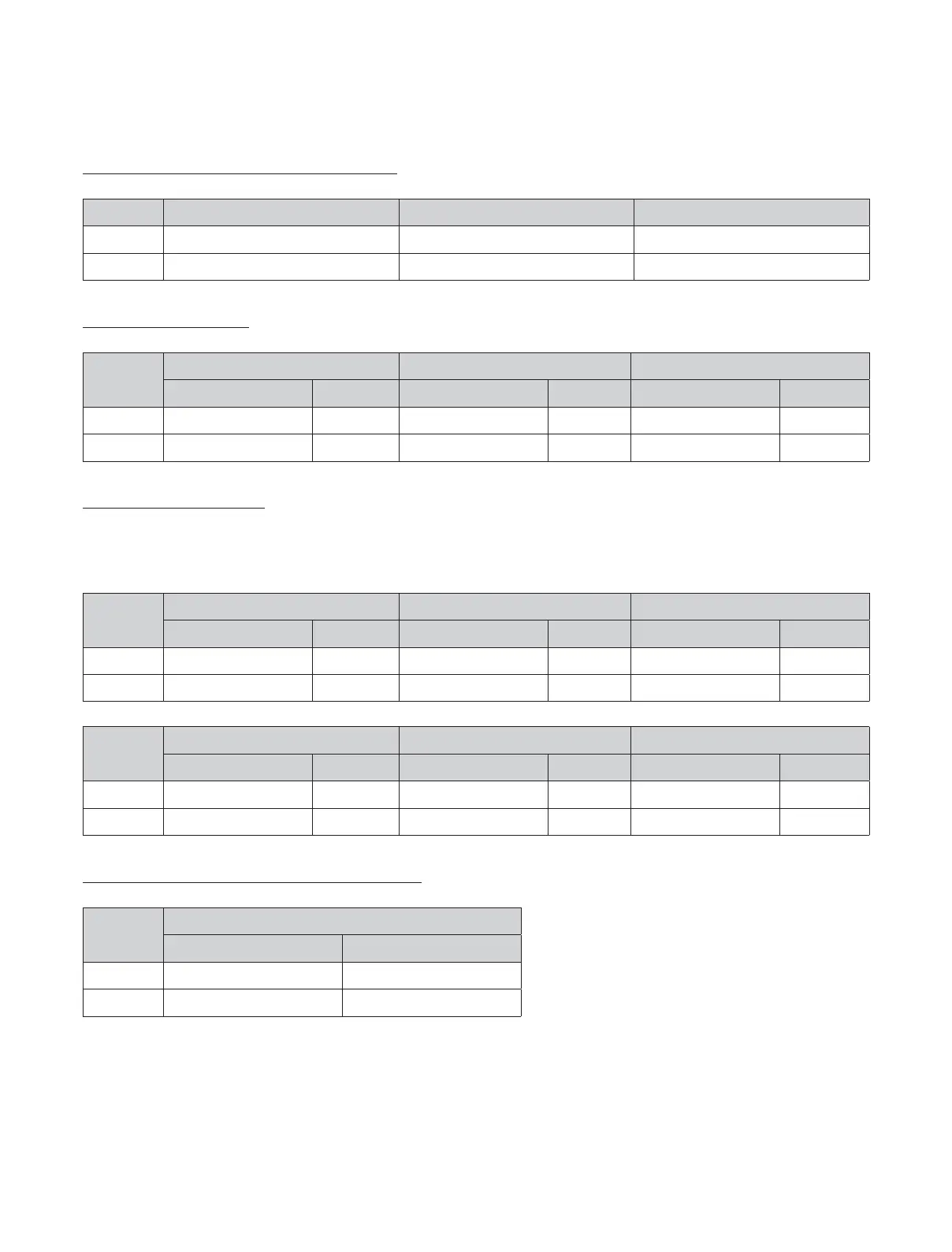

Pump Sizing for Use with Glycol

The use of glycol results in a greater head loss due to its higher viscosity compared to water. Heat transfer is also reduced as the glycol

concentration increases. The corrected flow rate and head loss values below must be used when sizing the boiler pump in order to maintain

similar performance as using 100% water for the heating system. Refer to the chart below.

Model

20°F T @ 30% glycol 25°F T @ 30% glycol 35°F T @ 30% glycol

Flow Rate (GPM) Head (Ft) Flow Rate (GPM) Head (Ft) Flow Rate (GPM) Head (Ft)

NFB-301C 32 12.6 25 8.9 18 4.8

NFB-399C 42 5.2 33 3.6 24 2.2

Model

20°F T @ 50% glycol 25°F T @ 50% glycol 35°F T @ 50% glycol

Flow Rate (GPM) Head (Ft) Flow Rate (GPM) Head (Ft) Flow Rate (GPM) Head (Ft)

NFB-301C 35 14.7 28 10.4 20 5.6

NFB-399C 46 6.0 37 4.2 26 2.5

Minimum Flow Rates through the Boiler for Use with Glycol

Model

Minimum Flow (GPM)

For Use With 30% glycol For Use With 50% glycol

NFB-301C 11 12

NFB-399C 13 14

Loading...

Loading...