Section 25 - Four-Wheel Drive Front Axle - Chapter 9

25-9-26

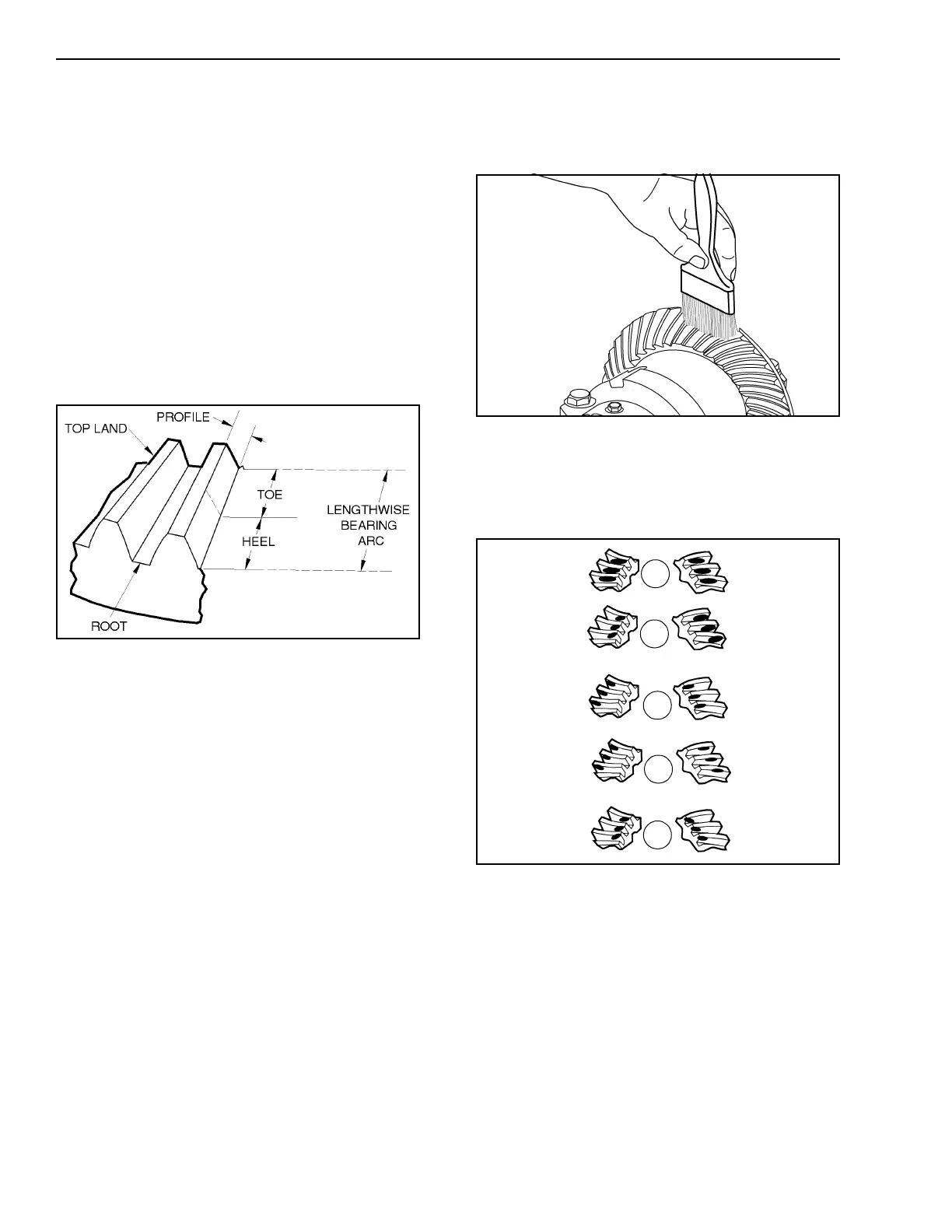

Ring Gear and Pinion Tooth Pattern Interpretation

When setting the pinion position, many of the service

manuals required a final pinion position check by

using gauges that verify the dimension from the

center line to the differential carrier (center line of the

ring gear) to the face of the pinion (button).

This surface (button) is not used on all new gears for

verifying the pinion position. The service tools will be

used to establish the proper amount of shims

required prior to installing the pinion gear. The final

pinion position will be verified by using the GEAR

CONTACT PATTERN METHOD, as described here.

Ring Gear and Pinion Tooth Contact Pattern

RH98K107

The toe of the gear tooth is the portion of the tooth

surface at the end towards the center. The heel of the

gear tooth is the portion of the tooth surface at the

outer end. The top land of a gear tooth is the surface

of the top of the tooth. Every gear has a

characteristic pattern. The illustrations show typical

patterns only, and explains how patterns shift as gear

location is changed. When making pinion position

changes, shims should be changed in the range of

0.05 mm (0.002 inch) to 0.10 mm (0.004 inch) until

correct pattern has been obtained.

When a change in backlash is required, backlash

should be changed approximately 1-1/2 times the

amount needed to bring the gears into specification.

For example, if the backlash needed to be changed

by 0.10 mm (0.004 inch), the adjusting rings should

be moved so that the backlash changes by 0.15 mm

(0.006 inch) as a starting point. The actual amount of

backlash change obtained will vary depending upon

the ratio and gear size once everything is tightened

to specification.

High backlash is corrected by moving the ring gear

closer to the pinion. Low backlash is corrected by

moving the ring gear away from the pinion.

1. Paint the ring gear teeth with a marking

compound to both the forward and reverse side.

RD02J026

2. Rotate the ring gear one complete revolution in

both directions.

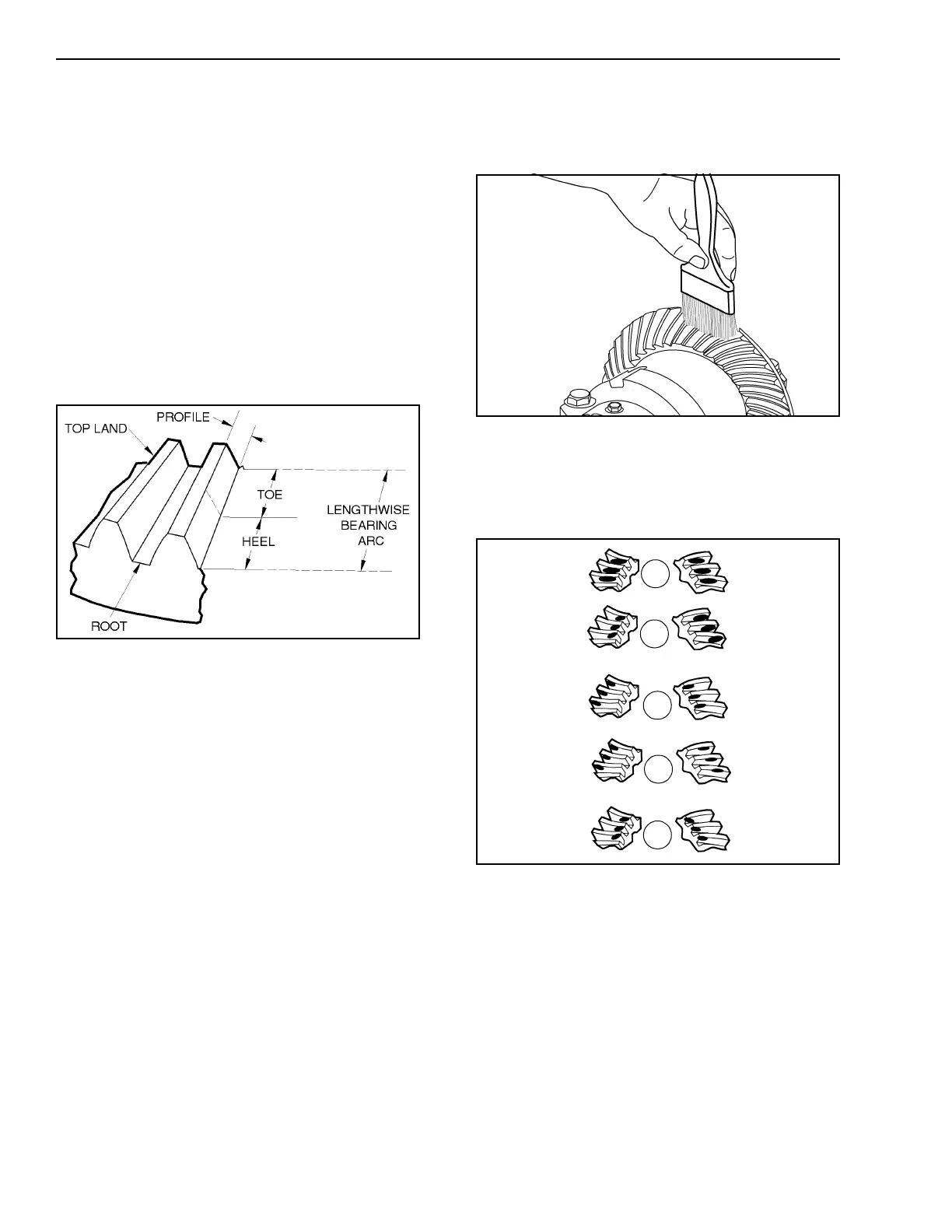

Pattern Interpretation (Ring Gear)

RH98K108

1. Normal or desirable pattern. The forward pattern

should be centered on the tooth, but slightly

toward the toe. There should be some clearance

between the pattern and the top of the tooth.

2. Backlash correct. Thinner pinion bearing cup

position shim required.

3. Backlash correct. Thicker pinion bearing cup

position shim required.

4. Pinion position shim correct. Decrease backlash.

5. Pinion position shim correct. Increase backlash.

FORWARD

DIRECTION

PATTERN

REVERSE

DIRECTION

PATTERN

1

2

3

4

5

Loading...

Loading...