Section 27 - Rear Axle - Chapter 1

27-1-23

HOW TO DETERMINE RAM PRESSURE

STEP 55

Do the following to determine what the pressure

gauge must show for your ram:

1. Determine the effective area of your ram.

2. Determine the minimum and maximum pressure

gauge readings desired.

Example: Find the effective area of twin rams,

each ram having a piston diameter of 1.5 inch.

The formula for the effective area is:

Effective Area = (2d + 2d) x 0.7854

d = diameter of each ram (1.5 inch)

2d = d x d or 1.5 x 1.5 = 2.25 sq. in. for each ram

Effective Area = (2.25 + 2.25) x 0.7854 = 3.534 sq. in.

EXAMPLE: Find the pressure gauge reading for the

specified minimum and maximum pound force using

a ram with 3.534 sq in effective area.

The formula for the pressure gauge reading is:

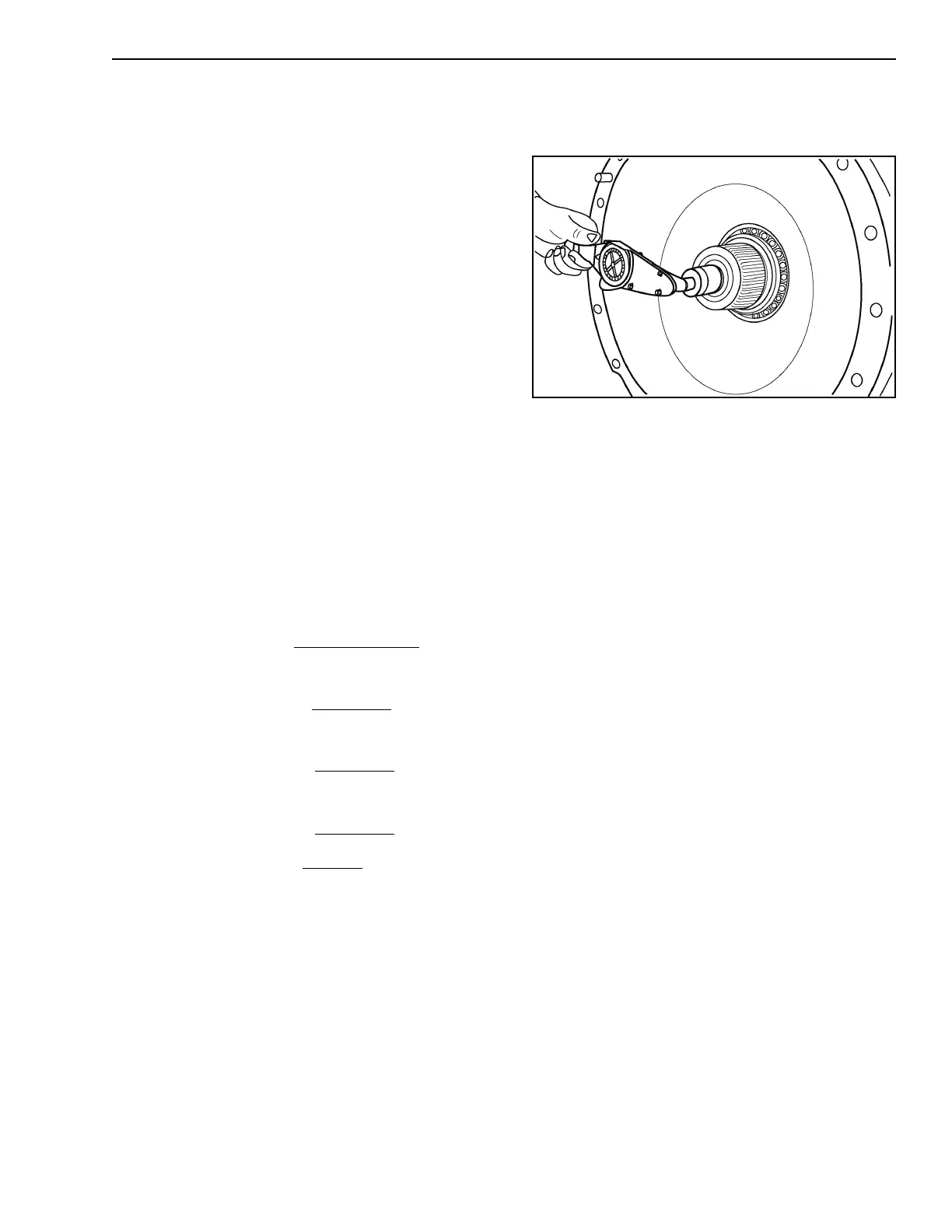

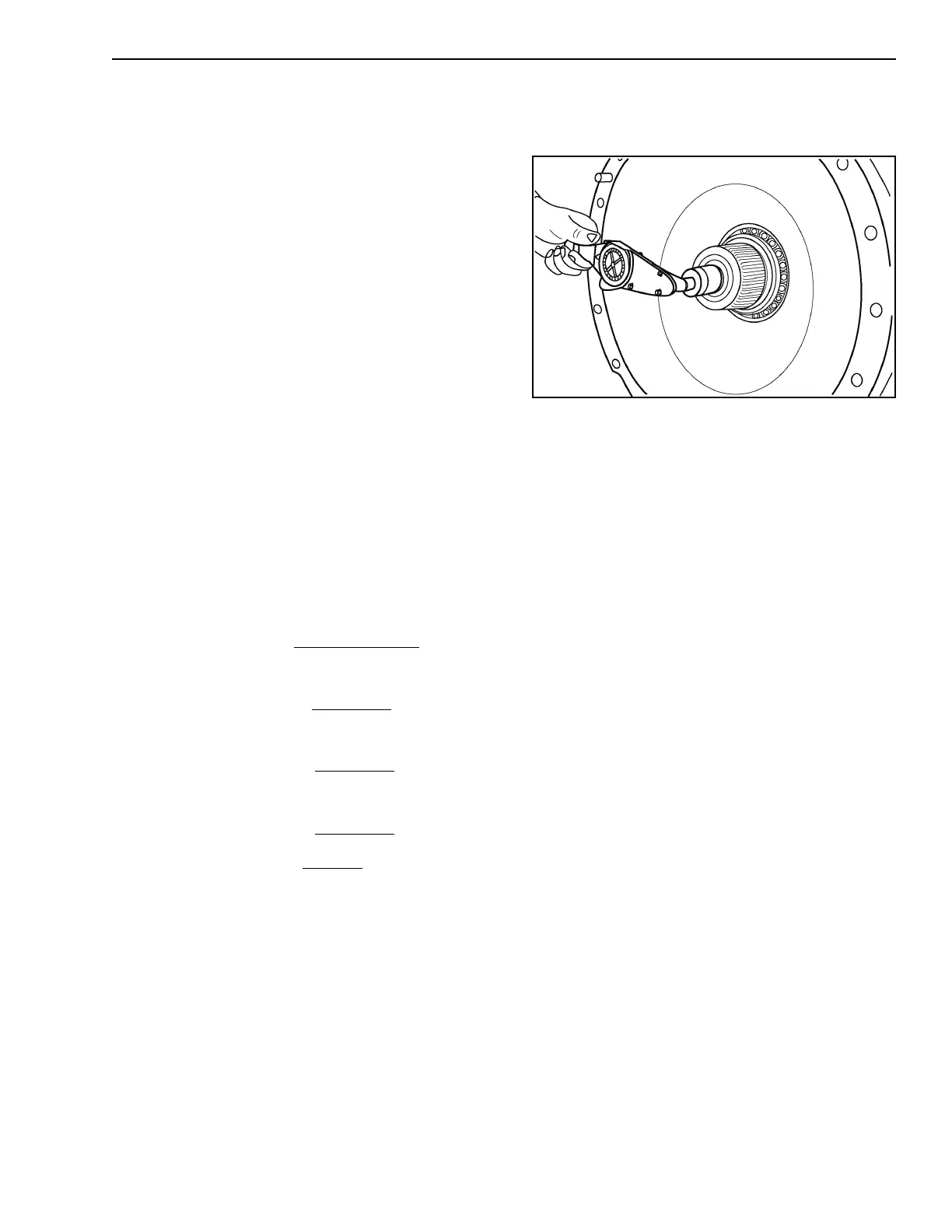

STEP 56

T97977

Check the axle assembly rolling torque. The final

specifications should be as follows:

98 inch (4-Inch Dia) Standard Axle

New Bearings .16.0 to 24.0 Nm (140 to 210 lb. in.)

Used Bearings .... 8.0 to 12.0 Nm (70 to 105 lb. in.)

98 & 120 Inch (4-Inch Dia) Heavy Duty Axles

New Bearings..16.0 to 26.0 Nm (140 to 230 lb. in.)

Used Bearings.....8.0 to 13.5 Nm (70 to 119 lb. in.)

120, Inch (4-1/2-Inch Dia) Axle

New Bearings ..18.0 to 28.0Nm (160 to 250 lb. in.)

Used Bearings .... 9.0 to 14.0 Nm (79 to 123 lb. in.)

NOTE: The rolling torque can be adjusted by adding

or subtracting shims. Changing the shim pack

thickness by 0.025 mm (0.001 inch) will change the

rolling torque approximately 2.3 Nm (20 lb. in.) for the

4-inch axle and 2.8 Nm (25 lb. in.) for the 4-1/2-inch

axle. Repeat above Steps until the axle rolling torque

is within specifications.

reading (psi) =

force in lb

effective area

Pressure Gauge Reading =

17000 lb

= 4810 psi

3.534

Pressure Gauge Reading =

21000 lb

= 5942 psi

3.534

Pressure Gauge Reading =

22000 lb

= 6225 psi

3.534

Loading...

Loading...