GEO T RIGGING PROCEDURE Page 35/63

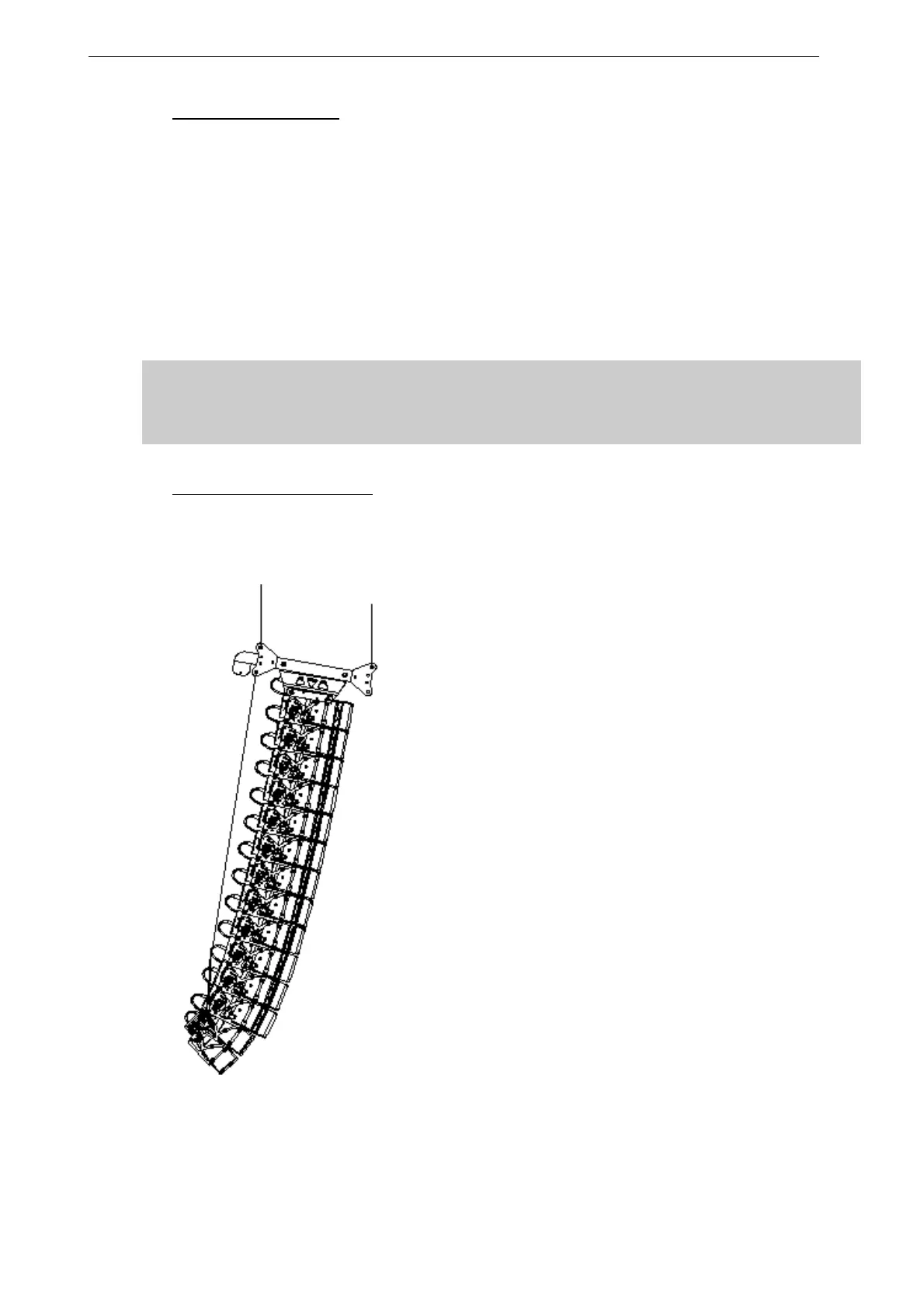

3.5.8 Positioning the cluster

• If one motor hoist only is used, the bridle chain length must be adjusted for the correct bumper

angle prior to cluster lift.

• Lift the GEO T array to the height determined in GeoSoft (GeoSoft array height definition is for

the top surface of the topmost cabinet).

• Adjust the bumper angle as determined in GeoSoft by lowering or lifting rear motor hoist (so that

the front height does not change).

• Check all GEO T angles with an inclinometer (cumulative error should always be lower than

0.5°).

• Once the bumper is in definitive position a secondary safety steel must be fitted (this secondary

safety steel should link the bumper to a suitable point in the supporting structure)

IMPORTANT

The requirements for secondary safety systems vary with territories. However, the

secondary safety steel MUST have a SWL equivalent to or greater than that of the rigging

system.

3.5.9 De-rigging and loading out

Taking the system down is just a case of doing the reverse procedure to flying the array. However,

there are some important factors to consider.

• Lower the array until the bottom cabinet is just

off the floor and the bumper is back to

horizontal.

• Rotate the LEVA1500 lever counterclockwise

until there is no tension on the GEO T kelping

chain and no compression on the system.

• Disconnect the LEVA1500 hook from the GEO

T bottom bumper and remove the bottom

bumper from the array. (You may have to

remove the T2815’s first)

• The array now hangs vertically.

• Link cables must be disconnected and stowed

away in the recesses in the rear of each

cabinet.

• NB : As the system is lowered it is good

practise to disconnect as many loudspeaker

cables as can be reached without climbing the

array. This ensures that a cable should not be

accidentally forgotten when the system is

separated. Damage to the connector will occur

should this mistake be made.

• In each group of 3 GEO T4805’s, the linking

bar of the lowest GEO T4805 should be

returned to the 5° position in order to sit flat in

the flight case.

•

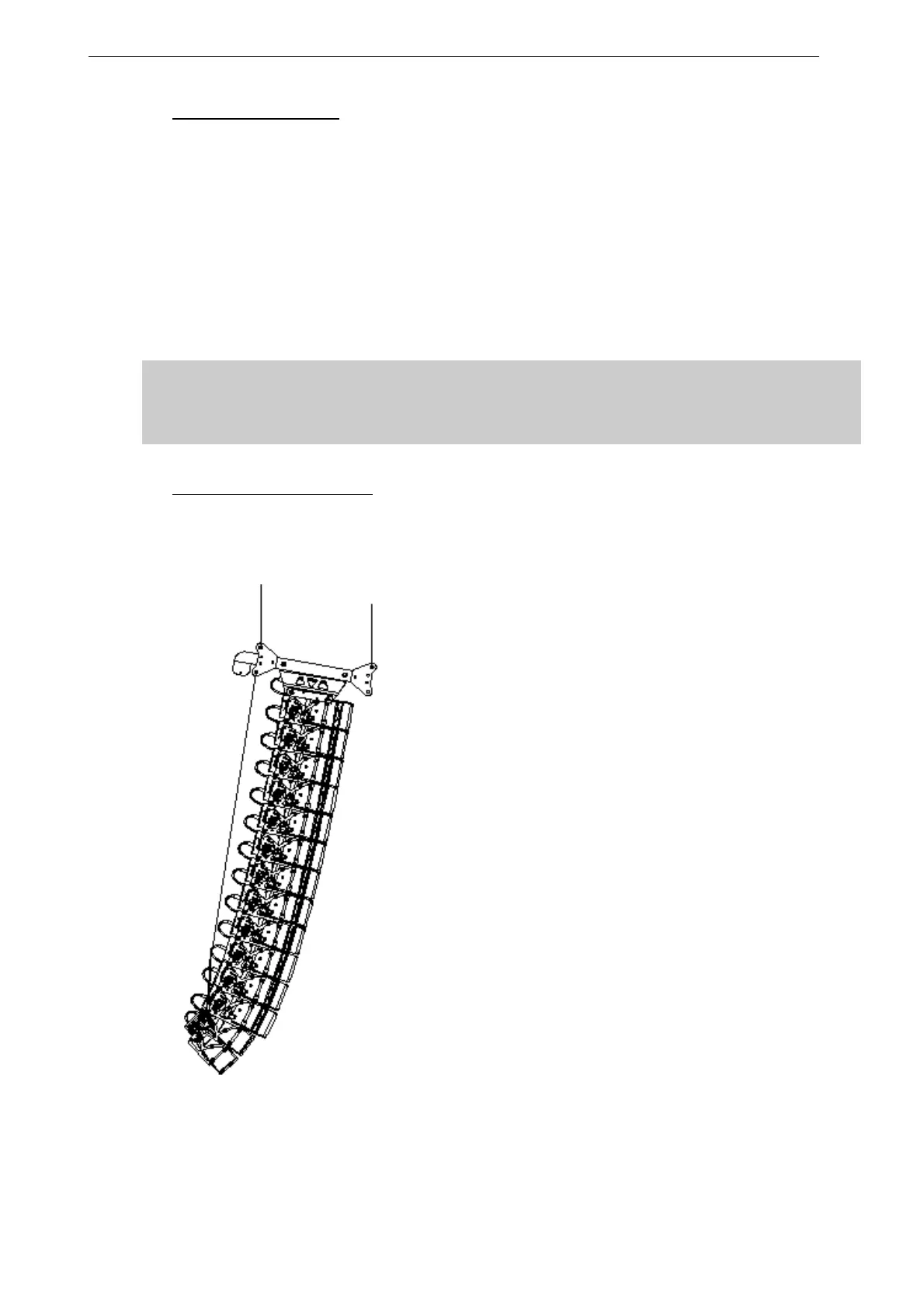

10 GEO T 4805 + 2 GEO T 2815 SET IN COMPRESSION MODE

Loading...

Loading...