OSEEX206-EN

8/10

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

HANDLING & STORAGE

HANDLING

Proper care in handling the valve should be taken to

prevent damage. Do not drop or throw it.

STORAGE

Store the actuator in the protected area from dust,

moisture, and direct sunlight. If possible, actuator

should be kept in the original packaging.

CHECKING

• Check the product code, power supply, and voltage

before installation.

• Confirm that there is no screw loose or part

deformation.

• DIP switch be sure perform set up before a power

supply injection. Should not change an unnecessary

switch.

INSTALLATION

PRECAUTIONS

• Flush the pipeline carefully before installing the valve.

Foreign particles, such as sand or pieces of welding

electrode, will damage the ball and seats.

• Do not cut too much threading of the pipe to be

connected.

It deforms the valve and it causes leakage.

• If seal tape or sealant protrudes into the valve,

malfunction may result.

Pay attention to tape treatment and coating amount.

• EG / SH type has a flow direction. Install the valve

accordingly.

• Specify the SC option if a steam fluid. Flow direction is

restricted by SC option. (MS type)

• When the flow path is subjected to a high pressure

from arrow, it may leak slightly to the low pressure

port. (EL / TV / ST / SL)

E EG SR SH H EL TV ST SL type

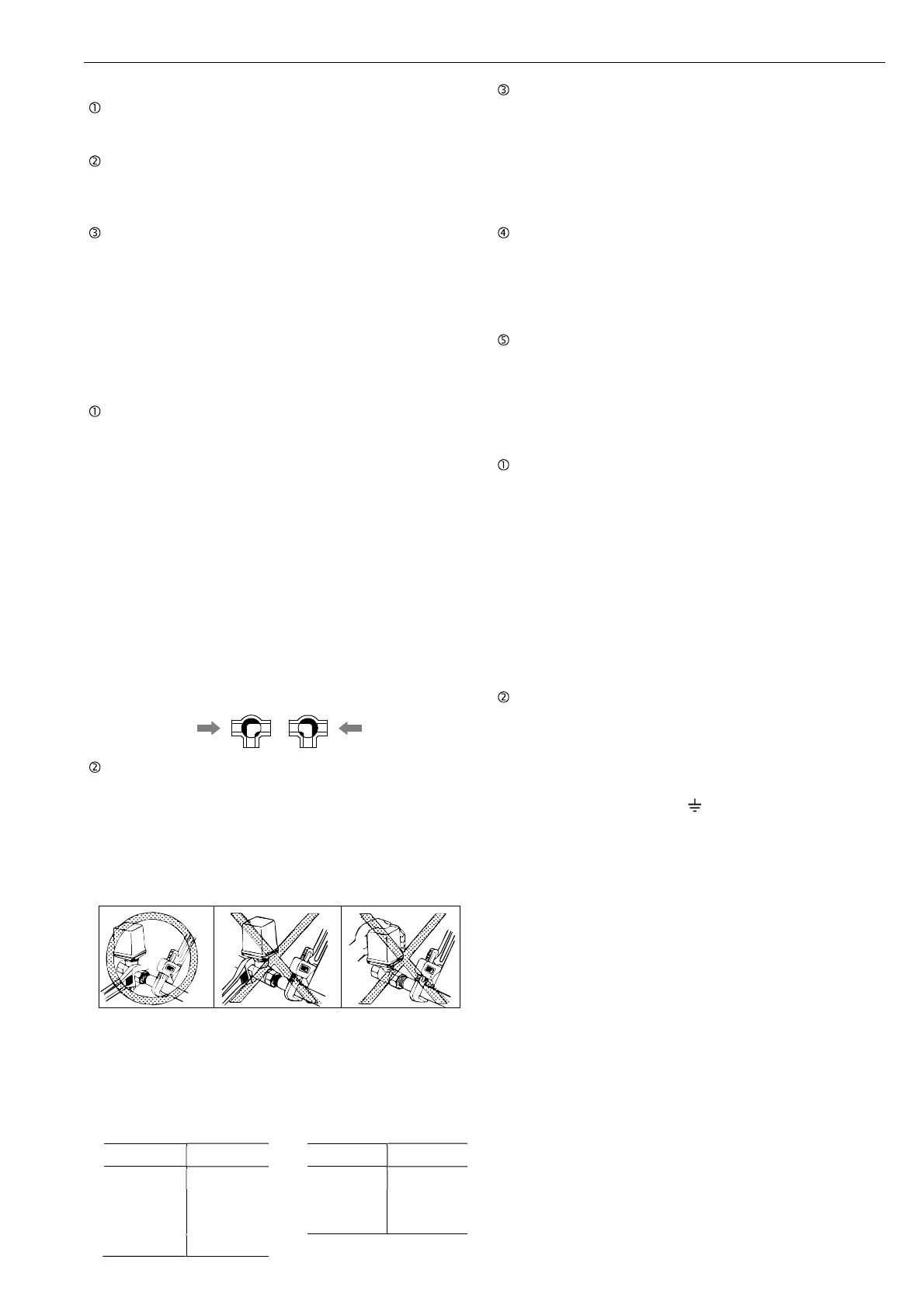

PIPING

• When piping, fix the end of the valve on the pipe side

with a smooth jaw wrench. (Fig. a)

• Do not place the wrench on the end of the valve

opposite the pipe to be connected. (Fig. b)

• Do not screw the valve into the pipe by holding the

actuator part with your hand. (Fig. c)

• Do not apply excessive force to the valve with a pipe

wrench or the like.

• When fixing the mounting posture,

please do not apply force in the loosening direction

(counterclockwise) of the coupling screw of the valve

body and cap.

Recommended torques [Nm]

Size [mm] Torque

008 to 010 15 to 25

015 25 to 35

020 40 to 50

025 50 to 60

Size [mm] Torque

032 60 to 80

040 75 to 85

050 90 to 110

ENVIRONMENT

• Do not install in place where corrosive gas is present

or where vibration is heavy (0.5 G or more).

• When radiant heat causes the surface temperature of

the control unit to exceed 50 °C, provide an

appropriate shielding plate.

• If there is a possibility that the fluid and drive part

freeze, please take measures to prevent freezing.

POSITIONING

• Should be positioned through 90° upward from

horizontal. Provide space around the product to allow

manual operation, inspection and replacement work.

• Maintenance space more than 105 mm upward from

the actuator is required.

OTHER NOTES

Until the wiring is completed there must be no

condensation or flooding in the interior of the actuator,

after piping. Protective caps on the cable gland are

not waterproof.

WIRING

PRECAUTIONS

• Remove the actuator cover before wiring.

• Two G1/2 electrical connections are provided with a

cable gland and plug. Usable cable size is 6 to 12

mm.

• When using a flexible tube, dew condensation may

occur inside the actuator due to respiration from the

inside of the tube and malfunction may result. Seal the

flexible tube connector part with a sealant.

• Sealants that affect the electrical contacts should not

be used inside the electric actuator.

• If long distance wiring or low voltage operation, check

that terminal voltage is in the proper range.

CONNECTION

• Do not wiring outdoors on a rainy day.

• Check the power supply and voltage.

Connect the signal as shown in the wiring diagram.

Do not connect unnecessarily terminal.

• Actuator should be electrically grounded.

Use the terminal marked ( ) inside the actuator.

PREVENT DEW CONDENSATION

• When installing the cover after wiring, perform the bolt

by the temporary tightening procedure and the

permanent tightening procedure to tightly and

securely tighten the rubber packing so that water does

not enter from the outside.

• Tighten the cable gland nut so that there is no leakage

from the wire entrance.

a b c

Loading...

Loading...