OSEEX206-EN

9/10

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

CONTROL

• When using control switch with current leakage

(more than 1 mA) such as TRIAC or relay with CR,

it can cause malfunction.

• Use signals within the capacity of output signal rating.

OPERATION

TESTING

• Make sure that power supply voltage is correct. Also

check operating position, wiring, speed and signals.

• During trial operation, check that valve movement and

OPEN and SHUT signals are correct.

DUTY CYCLE

Confirm that the operation frequency is within the

specified duty cycle.

Use beyond the load time rate range will affect

product life. Also, it may cause burnout.

Duty cycle is a value that regulates the opening /

closing frequency of the actuator. The meaning of

20% 15 minutes for Duty cycle is that 3 minutes

(20% of 15 minutes) operation is possible.

The calculated value obtained by dividing 3 minutes

by the operation time is the number of times of

operation within 15 minutes.

ATTENTION

• Keep power supplied for built-in space heater to

prevent condensation inside actuator.

• Do not touch the moving parts of actuator in

operation.

• Do not insert a reverse signal during operation.

It may shorten the life of product.

• Never put anything on the actuator or make it into a

foothold.

CAUTION

Since this actuator is designed for electric shut off,

even the power is turned off it may still operate for

about 30 minutes after power shuts off. Please follow

instructions when adjusting opening angle of the

valve or replacing parts.

MANUAL OPERATION

PRECAUTIONS

• Manual operation should be a temporary operation.

• Be sure to turn off the power before manual operation.

• Actuator may operate for 15 minutes after power

shuts off for ECR-120, and 30 minutes for ECR-360.

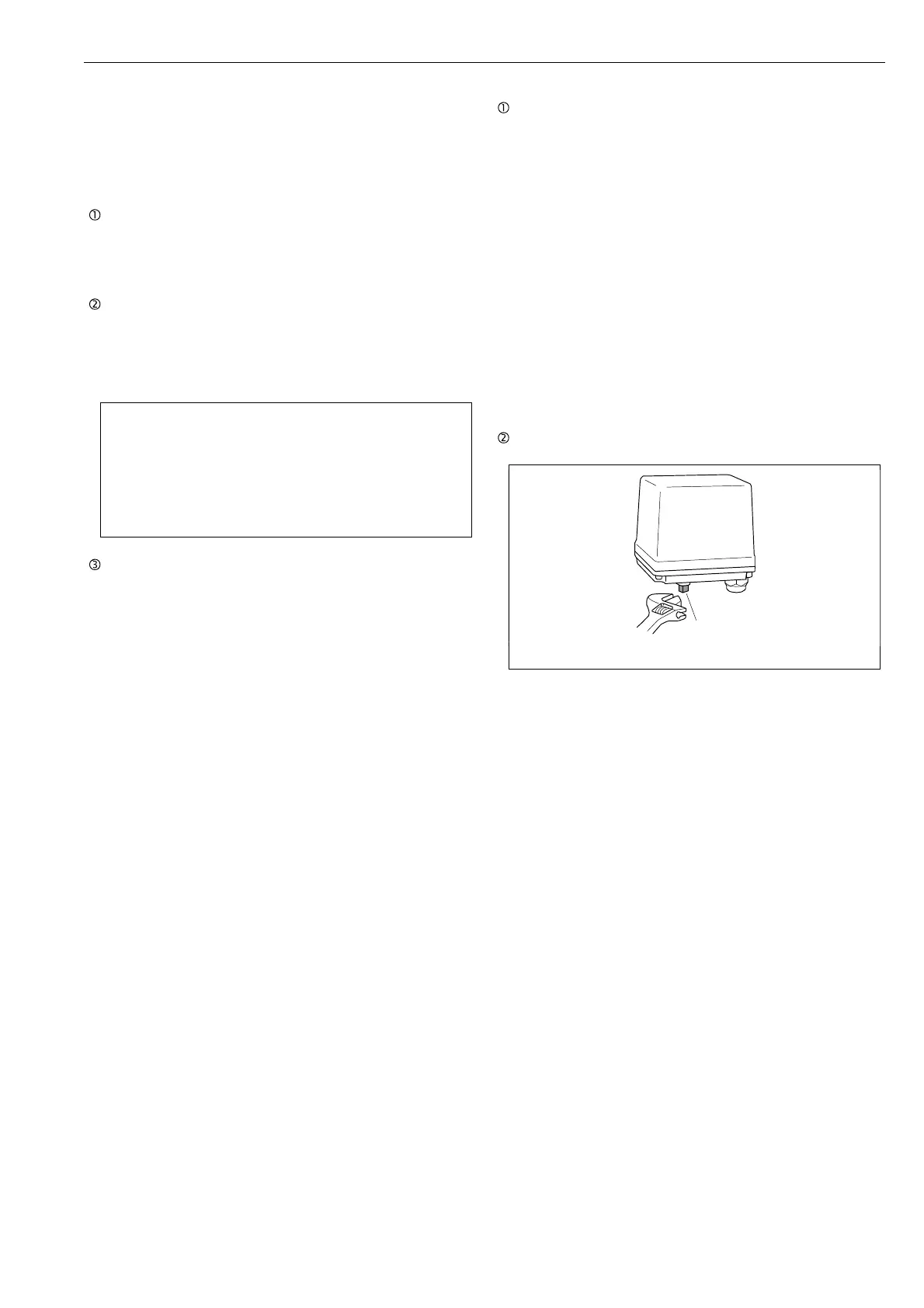

When manual operation is required, follow steps

below.

1) Turn manual shaft slowly with a

smooth-jawed wrench.

2) When limit switch leaves from SW setting

cam, actuator's motor starts.

Keep it in that position.

3) In about 30 seconds, motor protect circuit

starts and the motor stops.

Go ahead and operate manually.

THE WAY OF OPERATION

Turn manual shaft slowly with an adjustable wrench.

Before automatic operation, be sure to remove

wrench.

MAINTENANCE

• To prevent electric shock, be sure to turn off the power

when removing the actuator cover.

• Do the routine maintenance at least once in half a

year.

Inspection items

• Confirm operation of opening and closing.

• Confirm that an actuator is not hot excessively.

• Confirm existence of abnormal noise and

vibration during operation.

• Confirm whether screws are loose or not.

• Confirm that water or condensation no remains

in the actuator.

• Turn off the power and check if the valve

operates normally with built-in capacitor.

• Confirm the fluid temperature or pressure.

• Confirm the leak from valve stem.

• Confirm the bolt tightening torque.

Manual shaft

Loading...

Loading...