www.nord.com B1091-GB-3212 -11-

6. Motors for use in Zone 21

and Zone 22

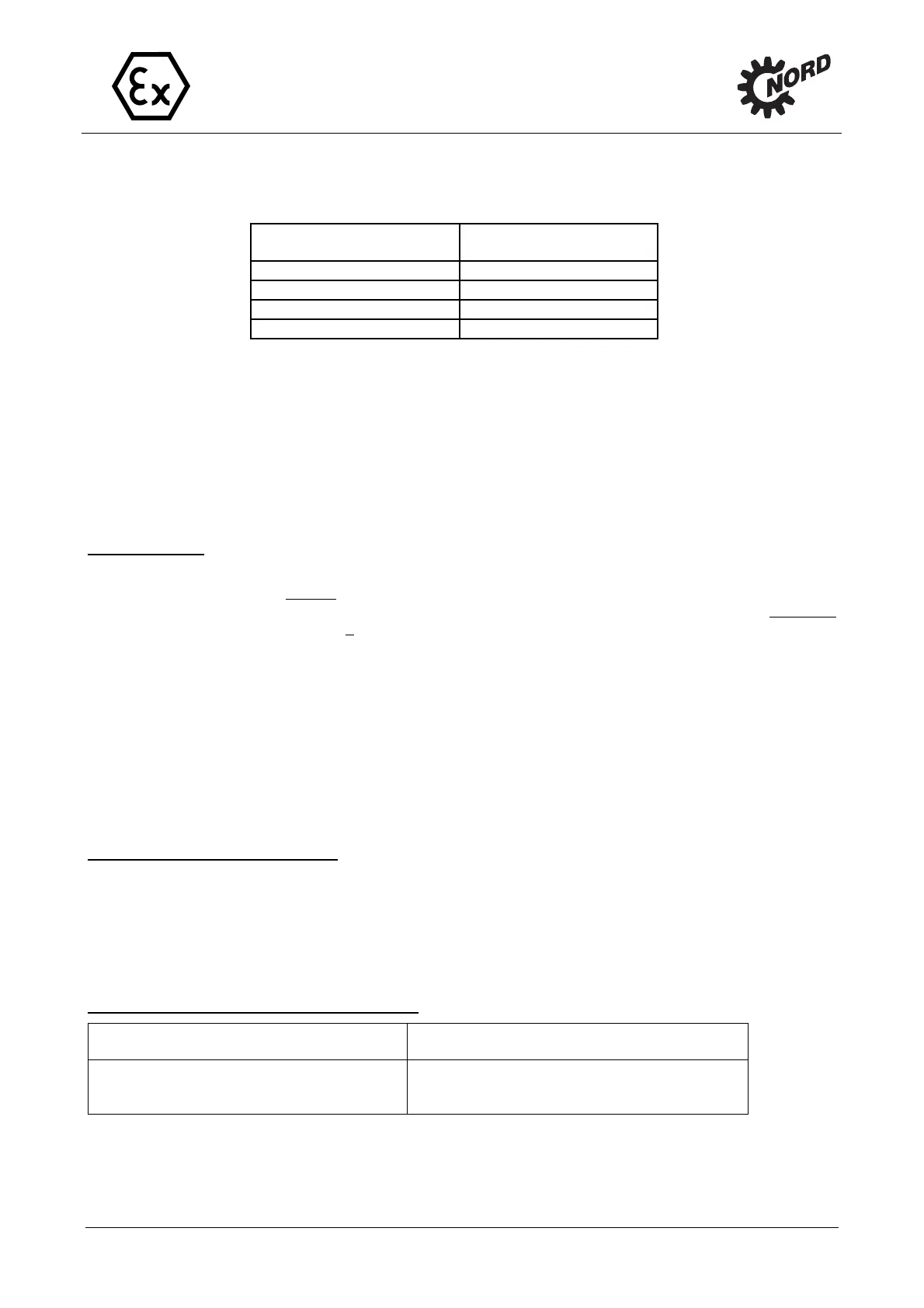

If the motor is supplied with a certified cable gland, the clamping nuts of the cable gland must be tightened to

the torque specified in the following table.

Cable gland Clamping nut tightening

torque [Nm]

M20x1.5 6

M25x1.5 8

M32x1.5 12

M40x1.5 16

The permissible ambient temperature range for all motors is -20°C...+40°C. A greater ambient temperature

range of -20°C...+60°C is permissible with motors for operation in Zones 21 and 22. This does not however

apply with the option brake and external fans! The rated power must then be reduced to 72% of the

catalogue value. If the maximum value of the ambient temperature is between +40°C and +60°C, the value

of the power consumption can be inversely interpolated linearly between 100% and 72%. Thermal motor

protection with a PTC temperature sensor is essential here. The motor connection cables and the cable

glands must be suitable for temperatures

90°C.

IEC-B14 motors

The B14 flanged bearing plate must be covered with a protective foil which must be removed before the

motor is fastened in place. All four fixing screws, even if not required, must be screwed into the flanged

bearing plate! The fixing screw threads must be inserted with a sealant, e.g. Loctite 242. The maximum

screw-in depth in the bearing plate is 2 x d.

If the shaft end faces upwards, e.g. models IMV3, IMV6, a cover must be positioned on the motor by the

operator/installer to prevent foreign bodies from falling into the motor ventilation cover (see

DIN EN 50 280-1-1). It must not hinder the motor from being cooled by the fans. Where shaft ends face

down, e.g. models IMV1, IMV5, the motors for Zone 21 are generally equipped with a protective roof on the

ventilation cover. A handwheel on the second shaft end is not permitted.

Unless otherwise specified for operating modes and tolerances in the test certificate or name plate, electrical

machinery is designed for continuous operation and normal infrequent start-ups where insignificant start-up

heating occurs. The motors may only be used for the operating mode specified on the name plate.

The installation regulations must be complied with!

6.4 Structure and operating mode

The motors are self-cooling. Rotary shaft seals are fitted both on the drive side (DS) and on the ventilation

side (VS).

Motors for Zone 21 and Zone 22 have metal fans. The motors are designed for protection class IP 55

(Zone 22 – non-conductive dust) or IP 66 (Zone 21). Under normal operating conditions the surface

temperature does not exceed that stated on the name plate.

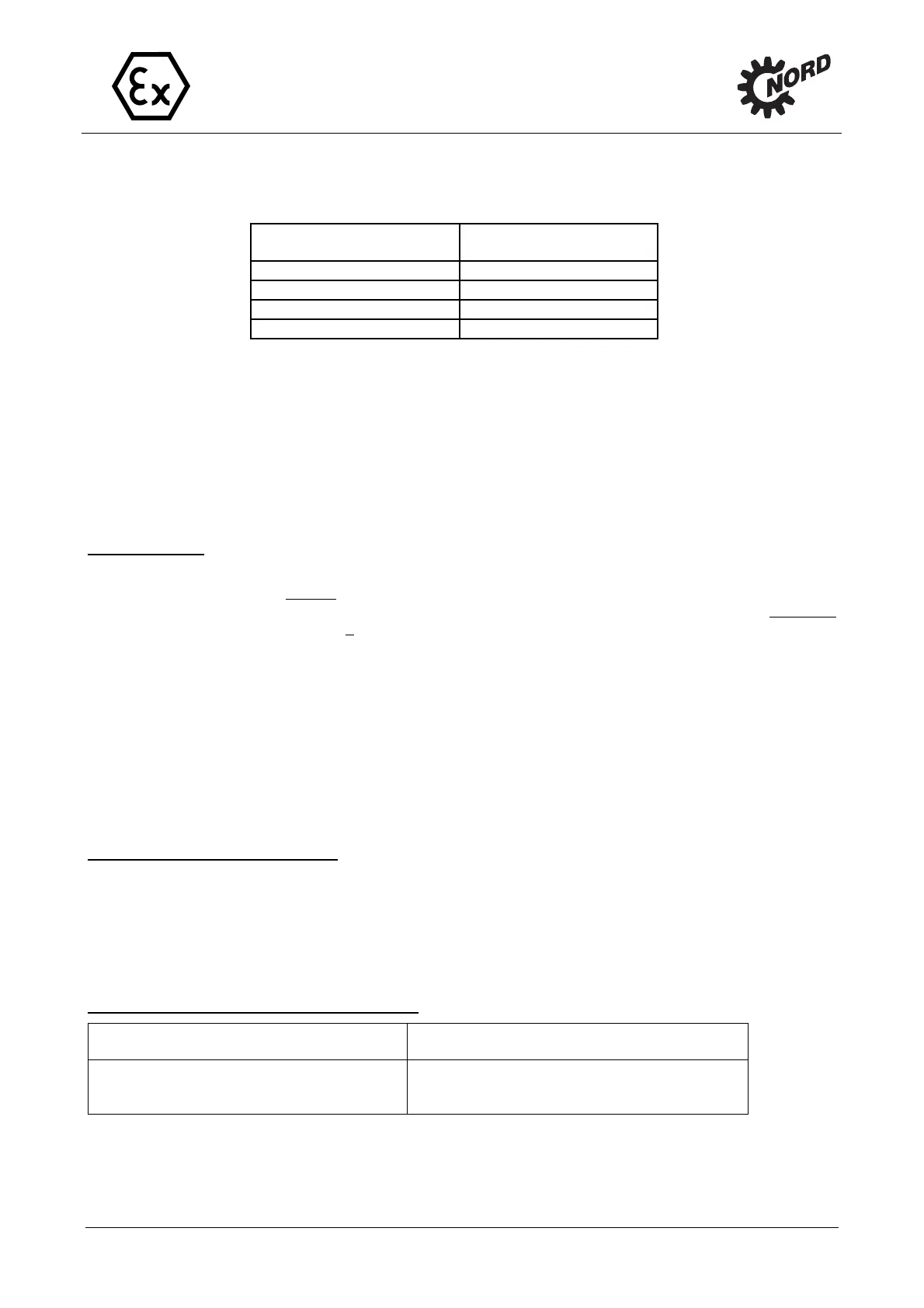

6.5 Minimum cross-sections of ground leads

Cross-section of phase conductor

in installation S in mm

2

Minimum cross-section of the associated

ground lead S

P

in mm

2

S ≤ 16

16 < S ≤ 35

S > 35

S

16

0.5 S

When connecting a lead to the external ground, the minimum cross-section must be 4 mm

2

.

Loading...

Loading...