9

• Connect the line-voltage leads to the

terminals on the contactor inside the control

compartment.

• Use only copper wire for the line voltage power

supply to this unit (Table 1). Use proper code

agency listed conduit and a conduit connector

for connecting the supply wires to the unit.

Use of rain tight conduit is recommended.

• See the unit wiring label for proper high and low

voltage wiring. Make all electrical connections

in accordance with all applicable codes and

ordinances.

• Use a separate branch electrical circuit for this

unit. A means of electrical disconnect must be

located within sight of and readily accessible

to the unit. This switch shall be capable of

electrically de-energizing the outdoor unit.

• Overcurrent protection must be provided at the

branch circuit distribution panel and sized as

shown on the unit rating label and according

to applicable local codes.

Outdoor Unit Connections

The outdoor unit requires both power and control

circuit electrical connections. Refer to the unit

wiring diagram / schematic for identifi cation and

location of outdoor unit fi eld wiring interfaces.

Control Circuit Wiring

The outdoor unit is designed to operate from a

24 VAC Class II control circuit. The control circuit

wiring must comply with the current provisions

of the NEC (ANSI/NFPA 70) and with applicable

local codes having jurisdiction.

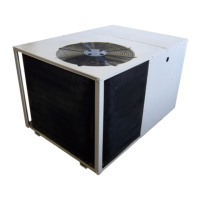

Thermostat Connections

Thermostat connections should be made in

accordance with the instructions supplied with

the thermostat, and with the instructions supplied

with the indoor equipment. See Table 2 for proper

wire gauge and their recommended lengths

for typical thermostat connections. A typical

residential installation with an air conditioner,

thermostat, and air handler is shown in Figure 2.

Figure 2. Typical 2-Stage Air Conditioner

with Variable Speed Air Handler

GRW

Thermostat

Y1C

Air Handler

A/C OD Section

Y1

W2

W1

O

Y/Y2

G

R

C

Y2

Y2

R

Y1

NOTE: Jumper

W1 and W2

together for

shorter staging

time. See Table 2

NOTE: in AC applications,

the O & Y connection must

be connected as shown.

Low-Pressure Switch

A low-pressure switch is factory installed and

located internally on the suction line of the

outdoor unit. The switch is designed to protect the

compressor from a loss of charge by interrupting

the thermostat inputs to the unit.

If the suction pressure falls below 5 psig, the

switch will open and de-energize the outdoor

unit. The switch will close again when the suction

pressure increases above 20 psig. NOTE: When

the switch opens and then closes, there is a 5

minute short cycling delay before the outdoor

unit will energize. Under normal conditions the

switch is closed.

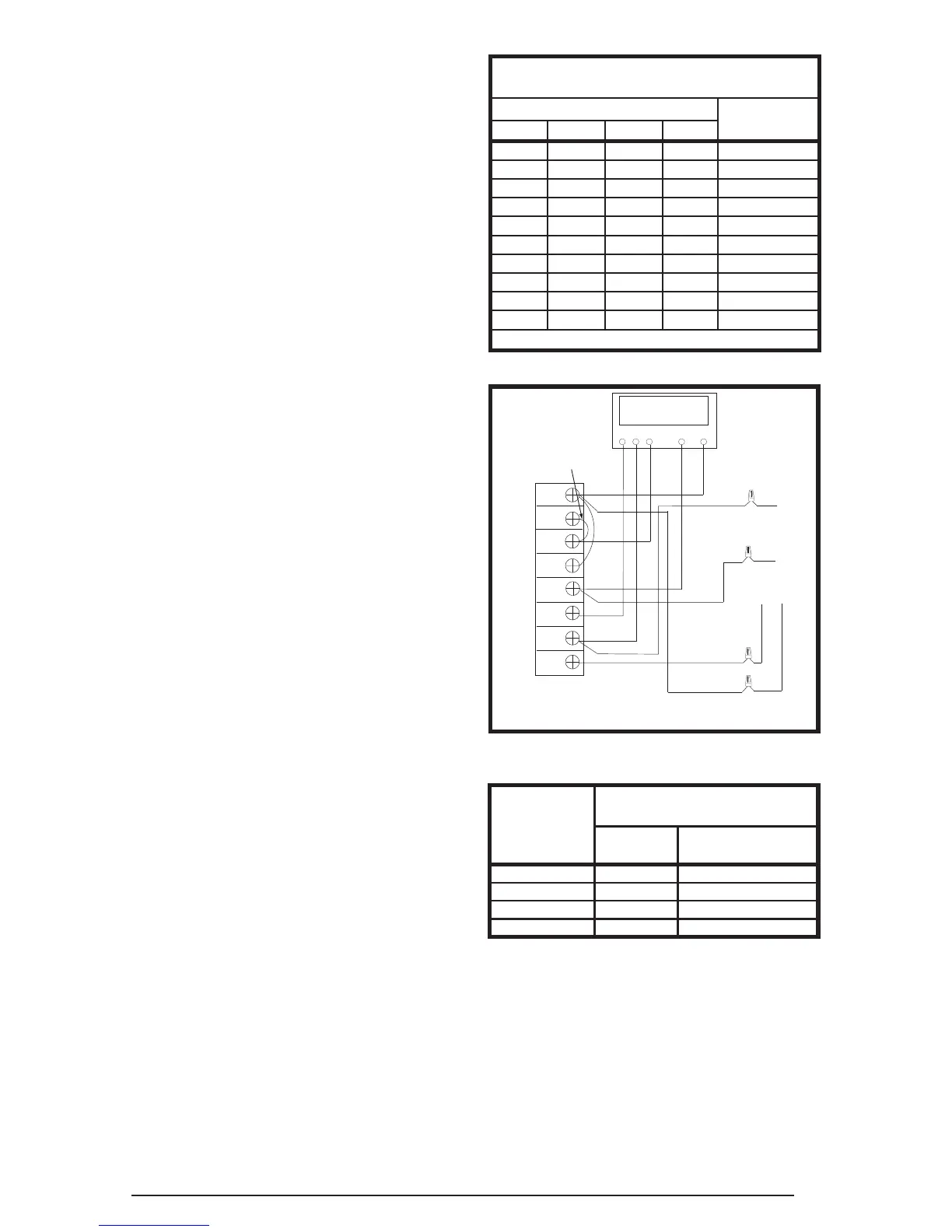

Table 2. Thermostat Wire Gauge

Thermostat

Wire Gauge

Recommended T’STAT Wire

Length (Unit to T’STAT)

2-Wire

(Heating)

5-Wire

(Heating/Cooling)

24 55 25

22 90 45

20 140 70

18 225 110

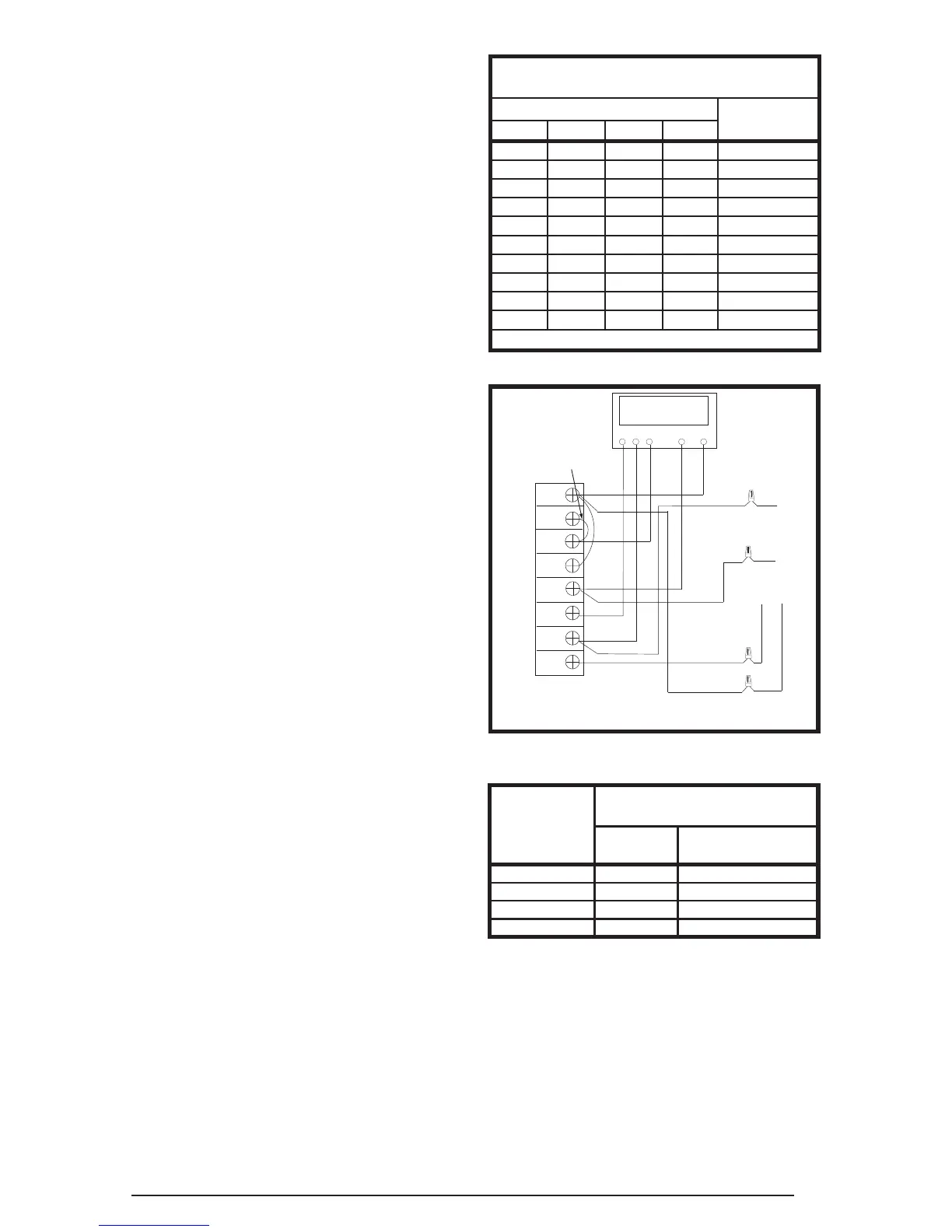

COPPER WIRE SIZE — AWG

(1% Voltage Drop)

Supply Wire Length-Feet

Supply Circuit

Ampacity

200 150 100 50

6 8 10 14 15

46812 20

46810 25

44610 30

3468 35

3468 40

2346 45

2346 50

2346 55

1234 60

Wire Size based on N.E.C. for 60° type copper conductors.

Table 1. Copper Wire Size

High-Pressure Switch

A high-pressure switch is factory installed and

located internally on the compressor discharge

line of the outdoor unit. If the discharge pressure

rises above 650 psig, the switch will open and

de-energize the outdoor unit. The switch will close

again after the discharge pressure decreases to

460 psig. NOTE: When the switch opens and

then closes, there will be a 3 minute short cycling

delay before the outdoor unit will energize. Under

normal conditions the switch is closed.

Loading...

Loading...