Do you have a question about the Nordyne T4BD-042 Series and is the answer not in the manual?

Details risks associated with electrical hazards and improper servicing.

Emphasizes proper handling of R410A and system pressure safety.

Covers unit purpose, performance, and basic installation requirements.

Discusses optimal placement and required clearances for the outdoor unit.

Guides on connecting refrigerant tubing and adjusting the outdoor unit's orifice.

Steps to verify voltage, supply, and wiring before electrical connection.

Details on connecting outdoor unit power supply, disconnects, and wire sizing.

Specifies grounding requirements and low voltage thermostat connections.

Information on the CoreSense module for system diagnostics and troubleshooting.

Steps to perform before starting the unit, including checks and procedures.

Verifies correct operation of the unit in cooling mode.

Verifies correct operation of the unit in heating mode.

Procedures for testing the defrost control board functionality.

Outlines essential maintenance tasks for optimal heat pump performance.

States that the compressor is hermetically sealed and requires no lubrication.

Detailed steps for charging the unit in AC cooling mode.

Provides charts and application notes for cooling mode refrigerant charging.

Presents tables and notes for refrigerant charging in heating mode.

Illustrates electrical connections for units equipped with CoreSense.

Shows electrical connections for units not equipped with CoreSense.

Depicts electrical wiring for units featuring a low pressure switch.

Verifies the integrity and correctness of the electrical system installation.

Checks critical refrigerant system parameters after installation.

Lists available replacement parts and provides ordering information.

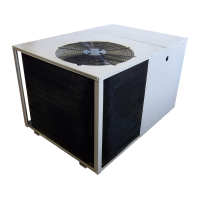

This document provides installation instructions for a Split System Heat Pump with Microchannel Coils, specifically the T4BD - 042, 048, & 060 (3.5, 4, & 5 Ton) Series Single Phase Models. It covers safety information, installation procedures, electrical wiring, startup and adjustments, maintenance, refrigerant charging, and wiring diagrams.

The device is a split system heat pump designed for outdoor rooftop or ground-level installations. It provides heating and cooling for conditioned spaces. The unit utilizes R-410A refrigerant and is shipped pre-charged. It incorporates a CoreSense™ Diagnostics Module (on select models) for troubleshooting system and compressor faults, and a defrost control board for managing defrost cycles.

Loading...

Loading...