15

Chapter4.–Installation

Vent Pipe Installation

• This Combi Boiler has a built-in control to limit the exhaust temperature to 149°F (65°C).

As a result, the Combi Boiler can be vented with Schedule 40 PVC.

• In high temperature applications, the exhaust temperature can exceed 149°F (65°C).

In that case, you must use Schedule 40 CPVC or Approved Polypropylene (PP) in the USA or Type BH

Special Gas Vent Class IIB (CPVC) or Class IC(Polypropylene) that conforms to ULC-S636 in Canada.

CAUTION

1. Turn off the control panel.

2. Press and hold the ‘Function Button’ for approximately

5 seconds to get into the ‘Installer Mode’.

3. Turn the ‘Dial Button’ clockwise until ‘6: Vt’ displays.

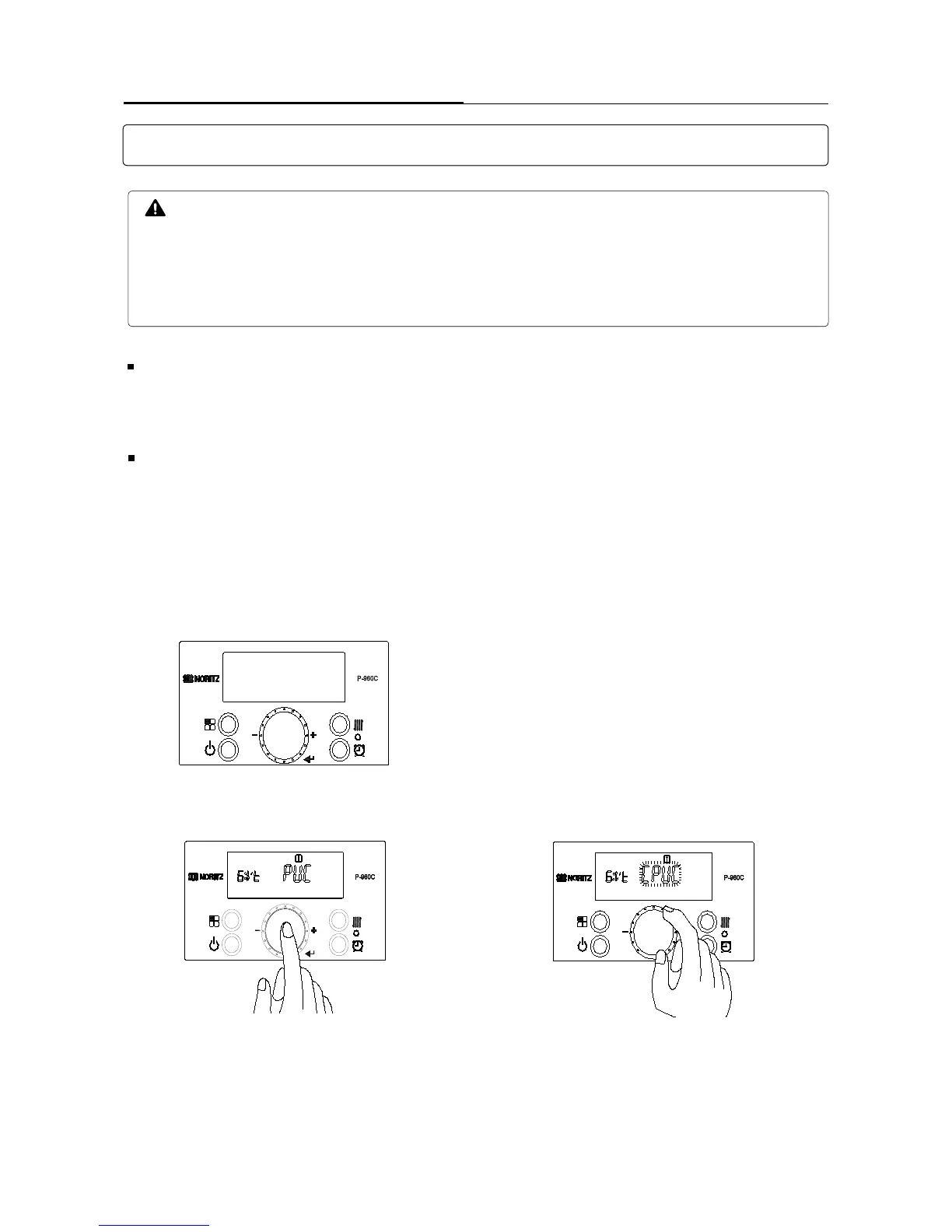

4. Press the ‘Dial Button’ (‘PVC’ will be blinking),

then turn the ‘Dial Button’ clockwise

so ‘CPVC’ is blinking.

1

2

3

5. Press the ‘Dial Button’ in order to

save the setting.

6. Press the ‘Function Button’,

to return to normal mode.

Vent Material Setting

• This Combi Boiler is set to "PVC" (factory default). The Combi Boiler will control and maintain the exhaust temperature

below 144°F (62°C) and the Combi Boiler will shut down when the exhaust temperature exceeds 149°F (65°C).

PVC Venting

• When you design a high temperature application (the exhaust temperature can exceed 149°F (65°C)),

you must use Schedule 40 CPVC or Approved Polypropylene (PP) in the USA or Type BH Special Gas Vent

Class IIB (CPVC) or Class IC(Polypropylene) that conforms to ULC-S636 in Canada and must change the

Vent Material Setting as follows.

• In this case, the Combi Boiler will control and maintain the exhaust temperature below 195°F (90.5°C)

and the Combi Boiler will shut down when the exhaust temperature exceeds 200°F (93°C) .

CPVC or Polypropylene(PP) Venting

Loading...

Loading...