12

8.

Vent Pipe Installation

(Indoor Installation Only)

WARNING

Be sure to do

CARBON MONOXIDE POISONING

Follow all vent system requirements in accordance

with relevant local or state regulation, or, in the

absence of local or state code, in the U.S. to the

National Fuel Gas Code ANSI Z233.1/NFPA 54 –

latest edition, and in Canada, in accordance with the Natural

Gas and Propane Installation Code CSA B149.1 – latest edition.

No. of Elbows

Max. Straight Vent Length*

4 39' (11.7m) N/A

3 45' (13.5m) 15' (4.5m)

2 51' (15.3m) 30' (9.0m)

1 57' (17.1m) 45' (13.5m)

Pipe diameter 4" (100mm) 5" (127mm)

•

This appliance has been designed to be vented

with 4" (100mm) PVC, CPVC or PP pipe.

•

This appliance has been designed to be vented

with 5" (127mm) N-Vent or Category III vent by

using 4" PVC to 5" SS Vent Adapter.

Do not exceed the following maximum vent lengths:

• The venting system shall be installed in

accordance with the water heater manufacturer's

instructions and, if applicable, the venting

system manufacturer's instructions.

• This is a Category IV appliance.

Only vent materials approved for use with

Category IV appliances should be used.

• Under normal conditions, this appliance will not

produce an exhaust ue temperature in excess

of 149°F (65°C) and schedule 40 PVC pipe may

be used as the vent material.

If the water heater

set temperature is 160°F (70°C) or higher and

there is a return line to the water heater from

either a recirculation pump or a combination

space heating system, schedule 40/80 CPVC

or PP must be used.

Refer to page 14 for additional requirements.

•

Make sure the vent system is gas tight and will not leak.

• Support the vent pipe with hangers at regular

intervals as specied by these instructions or

the instructions of the vent manufacturer.

•

All piping must be fully supported. Use pipe hangers

at a minimum of 3 ft (0.9 m) intervals. Do not use

the Water Heater to support the vent piping.

• Do not common vent or connect more than one

appliance to this venting system.

•

The total vent length including horizontal &

vertical vent runs should be no less than 3' (0.9m).

•

Steam or condensed water may come out from the

vent termination. Select the location for the termination

so as to prevent injury or property damage.

• If snow is expected to accumulate, take care the

end of the pipe is not covered with snow or hit

by falling lumps of snow.

• The vent for this appliance shall not terminate:

i) over public walkways; or

ii) near sot vents or crawl space vents or

other areas where condensate or vapor could

create a nuisance or hazard or cause property

damage; or

iii) where condensate vaper could cause

damage or could be detrimental to the

operation of regulators, relief valves, or other

equipment.

General Requirements Maximum Vent Lengths

* Not including the termination

Refer to page 17 for max. vent lengths

when using PVC Concentric Termination.

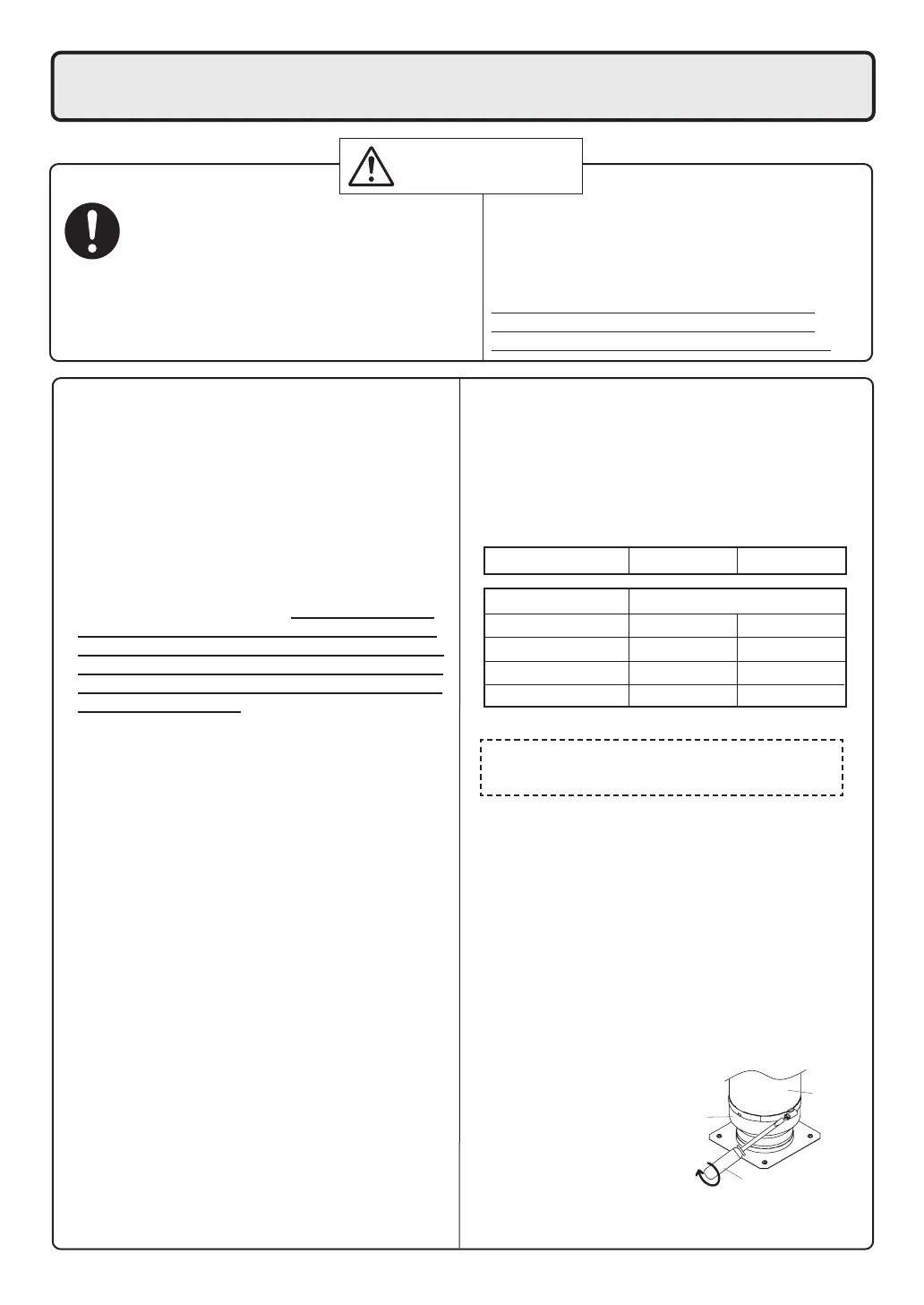

1. Continue to insert the Vent Pipe until it

reaches to the base of the unit Exhaust and

Intake Flue. (The Vent Pipe will be inserted

approximately 1.6"(40mm).)

2. Secure the Vent

Pipe by tightening

the band using a

screwdriver. (The

tightening torque

shall be more than

16 in lb.)

How to tighten the Vent Pipe

Exhaust and

Intake Flue

Vent Pipe

Screwdriver

-Flat head

-Box wrench(5/16")

Clearances

PVC, CPVC or PP has been approved for use on

this appliance with zero clearance to combustibles.

• The exhaust and intake pipes must be the

same vent pipe diameter.

Venting with PP pipe

• Do not deform the PP pipe when cutting.

• Deburr the cut end so that damage to the

gasket is avoided.

•

Remove debris from inside the pipe prior to assembly.

Damaged gaskets can cause leakage of

dangerous levels of carbon monoxide or

property damage due to condensate leaks.

Loading...

Loading...