41

(1) Open a hot water xture and conrm that the Burner On lamp comes on, and that hot water is

being produced. (If necessary, repeat until the air in the gas piping is bled out).

* White smoke may be noticed from the exhaust vent during cold weather. However, this is not a

malfunction of the unit.

* If an “11” error code appears on the remote controller, turn the unit o and then back on again,

and then open a hot water xture again.

(2) Change the temperature setting on the remote controller and check that the water temperature changes.

• If the water heater does not operate normally, refer to “Troubleshooting” in the Owner's Guide.

* After the trial operation, clean the lter in the cold water inlet.

<If installed with a quick connect multi-system>

• Turn the system power ON with the remote controller.

• Slowly open a hot water xture and check that the units ignite sequentially. Check to see that the

hot water temperature is the same as the temperature displayed on the remote controller (*1)

* If both units do not ignite, switch which unit will ignite rst by pressing the Max. or Min. Mani-fold

Pressure Set Button on the circuit board. (*2)

14.

Maintenance

Periodically check the following to ensure proper

operation of the water heater.

15.

Trial Operation

The installer should test operate the unit, explain to

the customer how to use the unit, and give the owner

this manual before leaving the installation.

• Preparation ........... (1) Open a hot water xture to conrm that water is available, and then close

the xture.

(2) Open the gas supply valve.

(3) Turn on the power supply. Using the remote controller, turn on the Power

On/O button (the Operation lamp will turn on).

• The venting system must be examined periodically by a qualied service technician to check for

any leaks or corrosion.

• The burner ame must be checked periodically for a proper blue color and consistency.

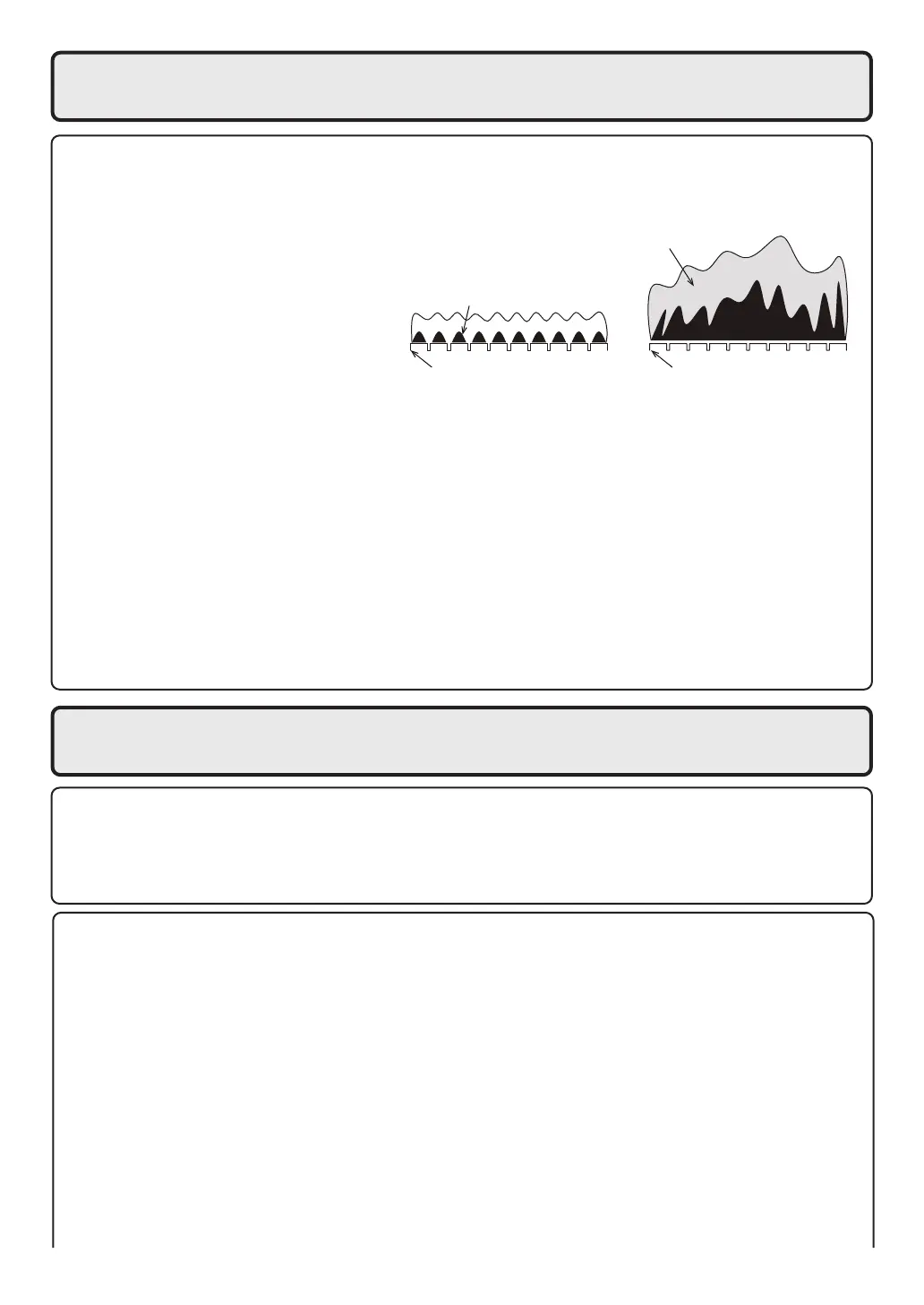

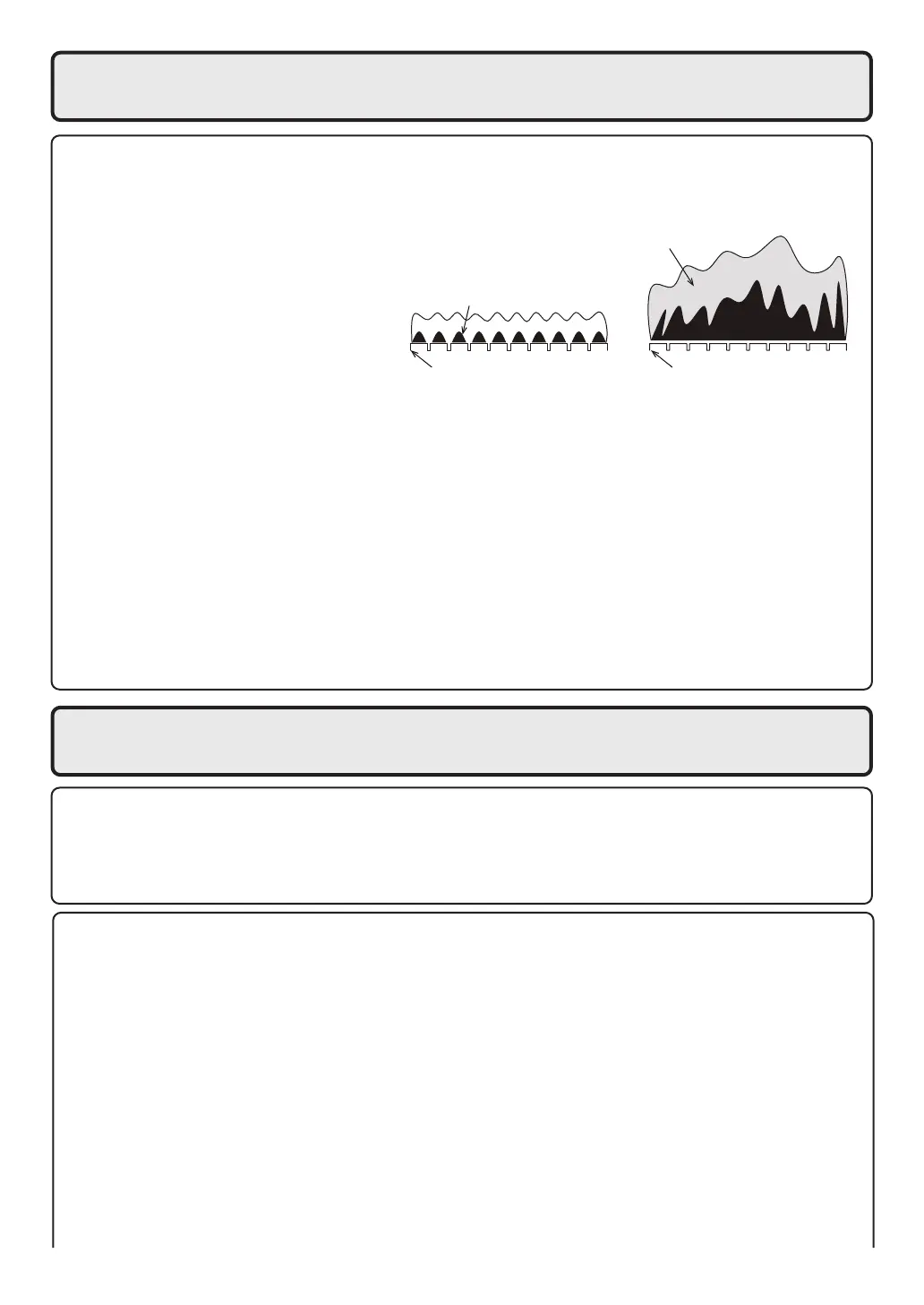

• Check the burner ame periodically for a

proper blue color and consistency. The

burner ame must be blue, clear and

stable.

The image of normal or abnormal ame

is as shown right gure. If the ame

does not appear normal, the burner may

need to be cleaned by qualied service

technician.

• Do not obstruct the ow of combustion and ventilation air.

• The pressure relief valve must be operated once a year to ensure that it is functioning properly and

there is no obstruction. Turn the power o to the unit before opening the relief valve, and make sure

that water draining out of the valve will not cause any damage.

• If the relief valve discharges periodically, it may be due to thermal expansion in a closed water

system. Contact the water supplier or a local plumbing inspector on how to correct this situation.

Do not plug the relief valve.

• See the Owner's Guide for further maintenance.

Warning:

There is a scald potential if the output temperature is set too high.

Should overheating occur, or the gas supply fail to shut o, turn o the manual gas control valve to the appliance.

Do not use this appliance if any part has been under water. Immediately call a qualied service

technician to inspect the appliance and to replace any part of the control system and any gas control

which has been under water.

Periodically check and clean the lter inside the cold water inlet of the unit.

e.g.) Normal Burner Flame e.g.) Abnormal Burner Flame

Burner

Blue Flame

Burner

Lifting Flame

Loading...

Loading...