9

EVAPORATOR & CONDENSER BLOWER MOTOR ASSEMBLIES

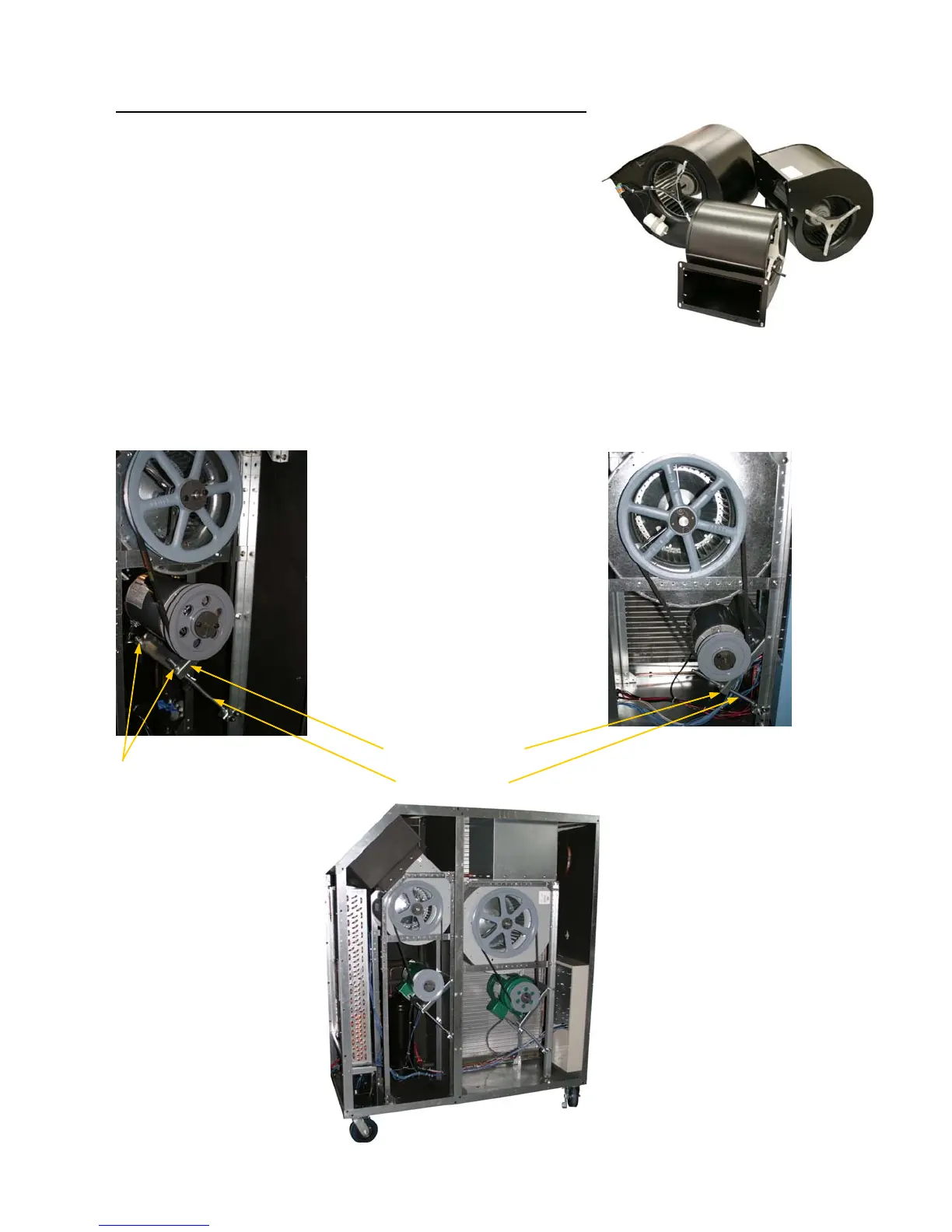

Each 1 and 1½ ton unit is equipped with a new technology external rotor,

forward curved, squirrel cage blower for the evaporator and condenser sec-

tions. The external rotor motor is totally enclosed, PSC, thermally protected,

2-speed, with sealed ball bearings, and dynamically balanced in 2 planes for

reduced noise/vibration levels. The blower wheel is bolted to the rotating

stator section, eliminating set screws. The double inlet design puts the motor

section in the center of the wheel, leaving both air inlets free of any motor

obstruction and in the air stream for cool efficient operation, unlike standard

direct drive blowers. No oiling or mechanical servicing is required.

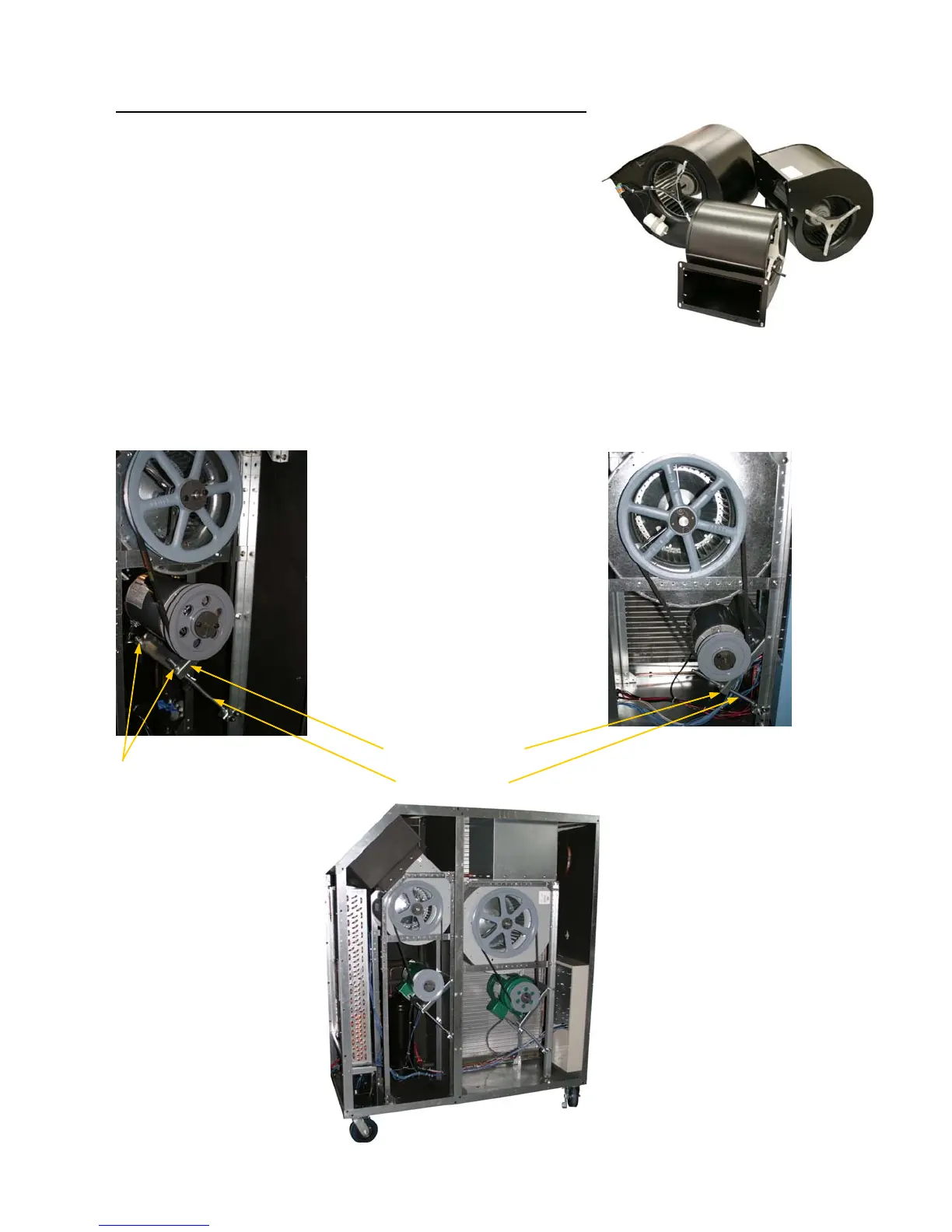

MAC60/90 models utilize belt drive blowers/motors which provide the increased air flow at very moderate noise

levels. All motor pulleys are keyed to the shaft and secured with tapered style bushings. Blower pulleys are secured

with tapered bushings, eliminating the need for set screws.

The motors are solidly bolted to the motor mounting plate. Adjustment and belt tension are easily set by raising or

lowering the plate and tightening the adjustment bolts.

Motor mounting plate

Adjustment rods

Belt adjustment/replacement is easy. Just

loosen the nuts on the top and bottom of

the motor plate, roll off the old belt...roll

on the new one… tighten the bolts to ap-

ply tension to the belt and motor plate.

Lock nuts on top and bottom

of motor mounting plate

MAC60 condenser blower

MAC60 evaporator blower

Inside view of MAC90

showing the arrangement of

internal components.

Loading...

Loading...