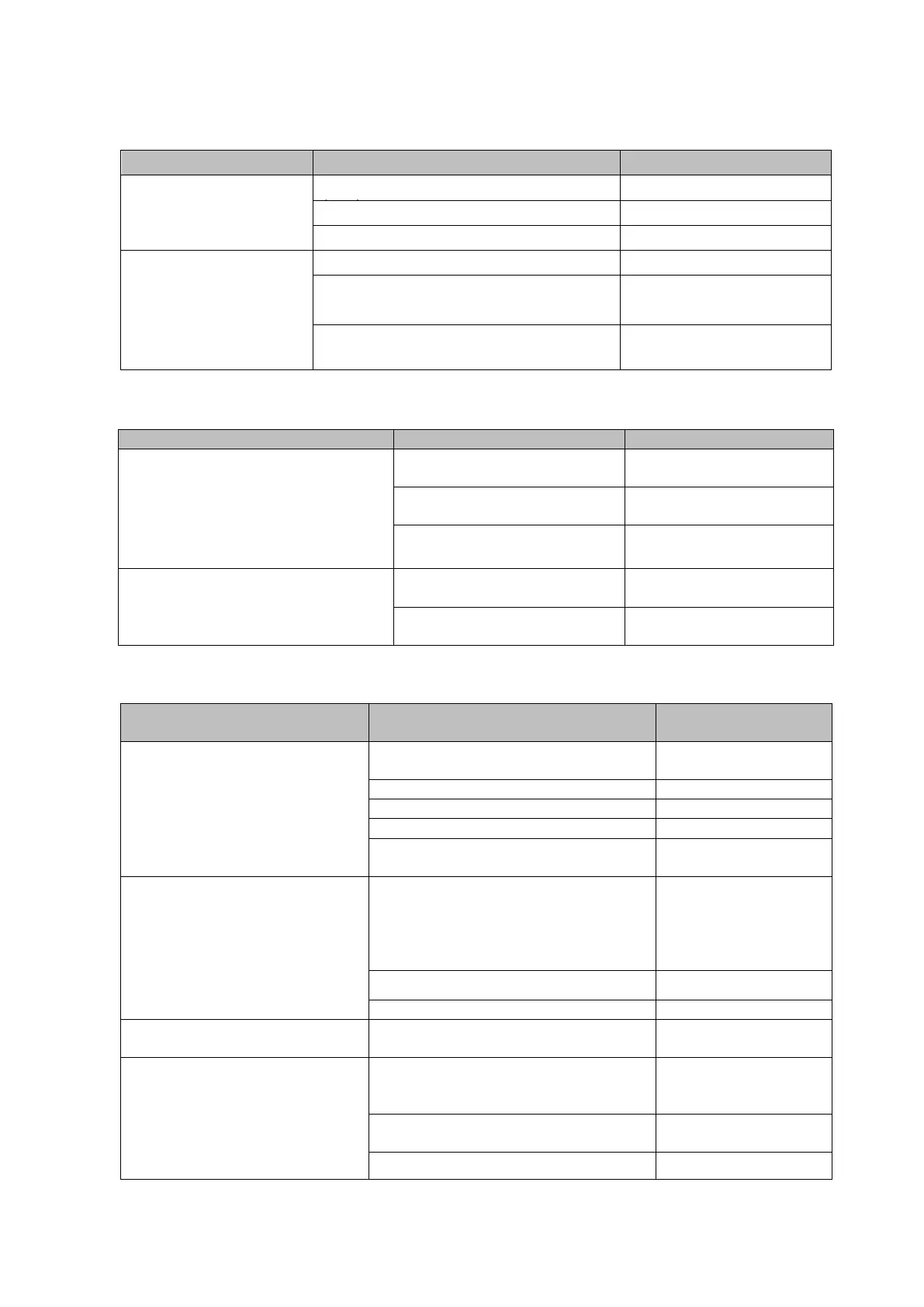

Brakes are not

sensitive enough.

There is grease or oil on brake

bands.

Brake bands are excessively worn.

The free stroke of brake is

excessive.

The free stroke is too small.

It’s too small of the clearance

between the brake bands.

The brake arm does not return.

Check whether the return

spring works.

Steering clutch slips (with heavy

loads, the sound of exhaust pipe isn’t

heavy, but the bulldozer gives a weak

traction force, when traveling slowly

or turning to one side without

controlling the steering system).

There is grease or oil on the

clutch disc.

The clutch disc is excessively

worn.

The steering free stroke is too

small

The steering will not disengage

completely.

The free stroke of steering is

excessive.

The free stroke of brake is too

small.

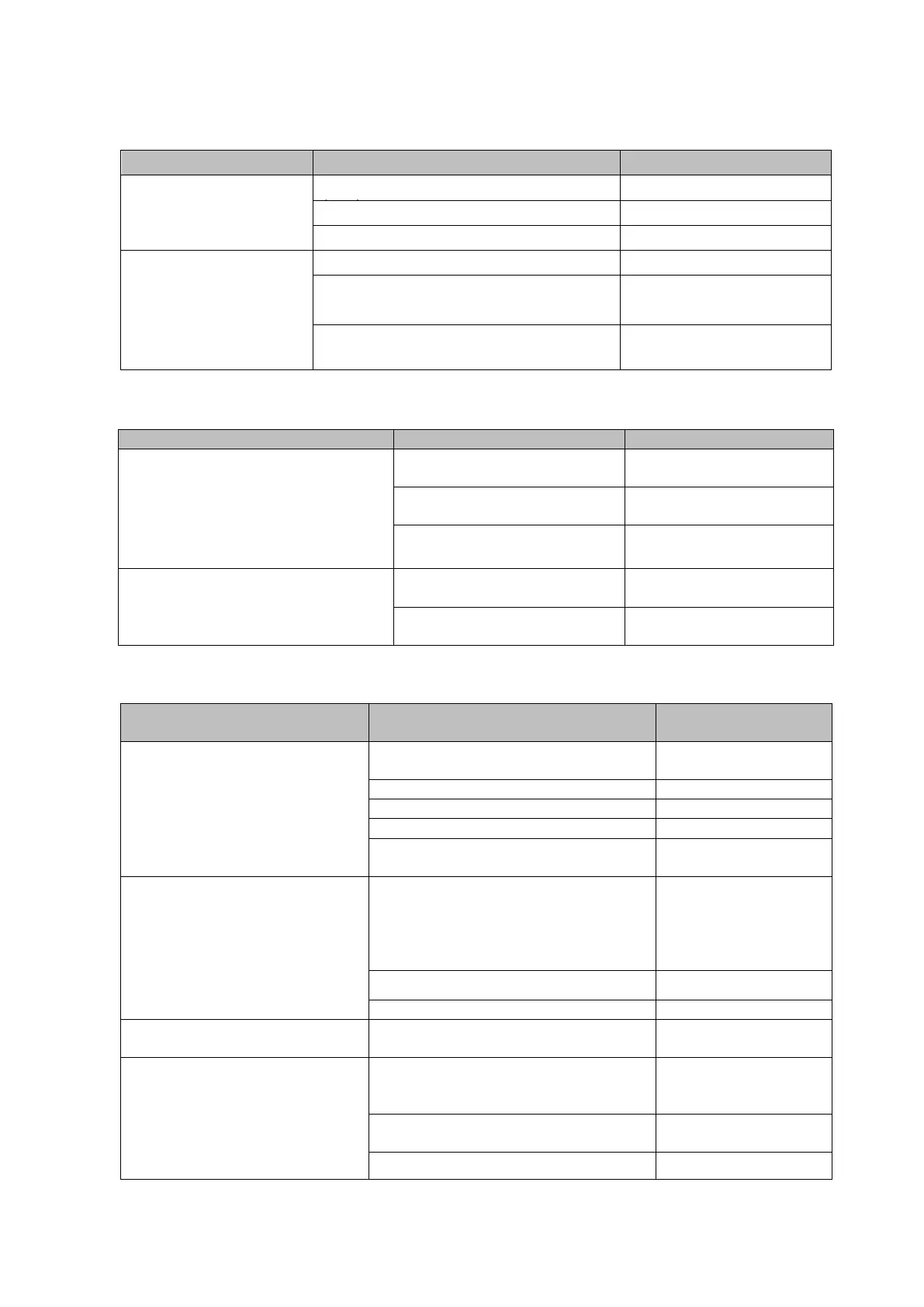

Load will not lift or lifts slowly.

There’s much air in the system.

Check the system for

leakage and repair.

Pressure is too low in the relief valve.

The cylinder sealing ring is damaged.

There is a serious leak inside the oil

pump.

Unable to lift without load.

There is no pressure of the system.

The hydraulic tank is short of oil. The

ring sealing of the joint is damaged or

it’s not torqued enough to tighten the

oil pump.

Supply oil according to

requirements.

Replace the ring or

retighten the pump.

The cylinder’s ring doesn’t work.

There’s a leak at the relief valve.

Unable to lower after lift.

Main control valve is blocked at the lift

position.

Blade or 3-point hitch system

vibrates during lift, lifts poorly, or

fails to lift.

It’s badly worn and poorly sealed

between the main control valve body

and the valve spool.

Cylinder is badly worn and the seal

ring is damaged.

Poor sealing in the relief valve.

Loading...

Loading...