- 39 -

TOOL BREAKAGE

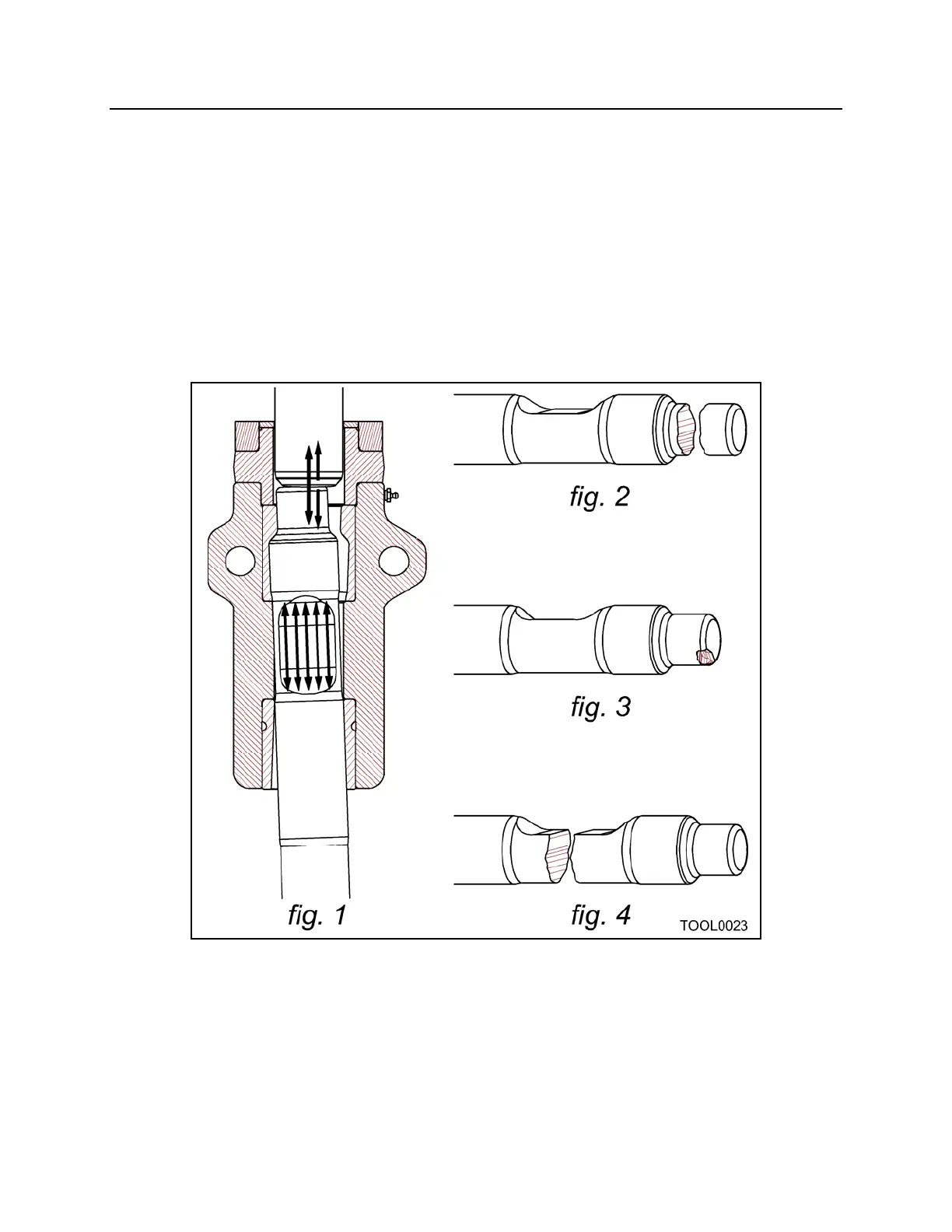

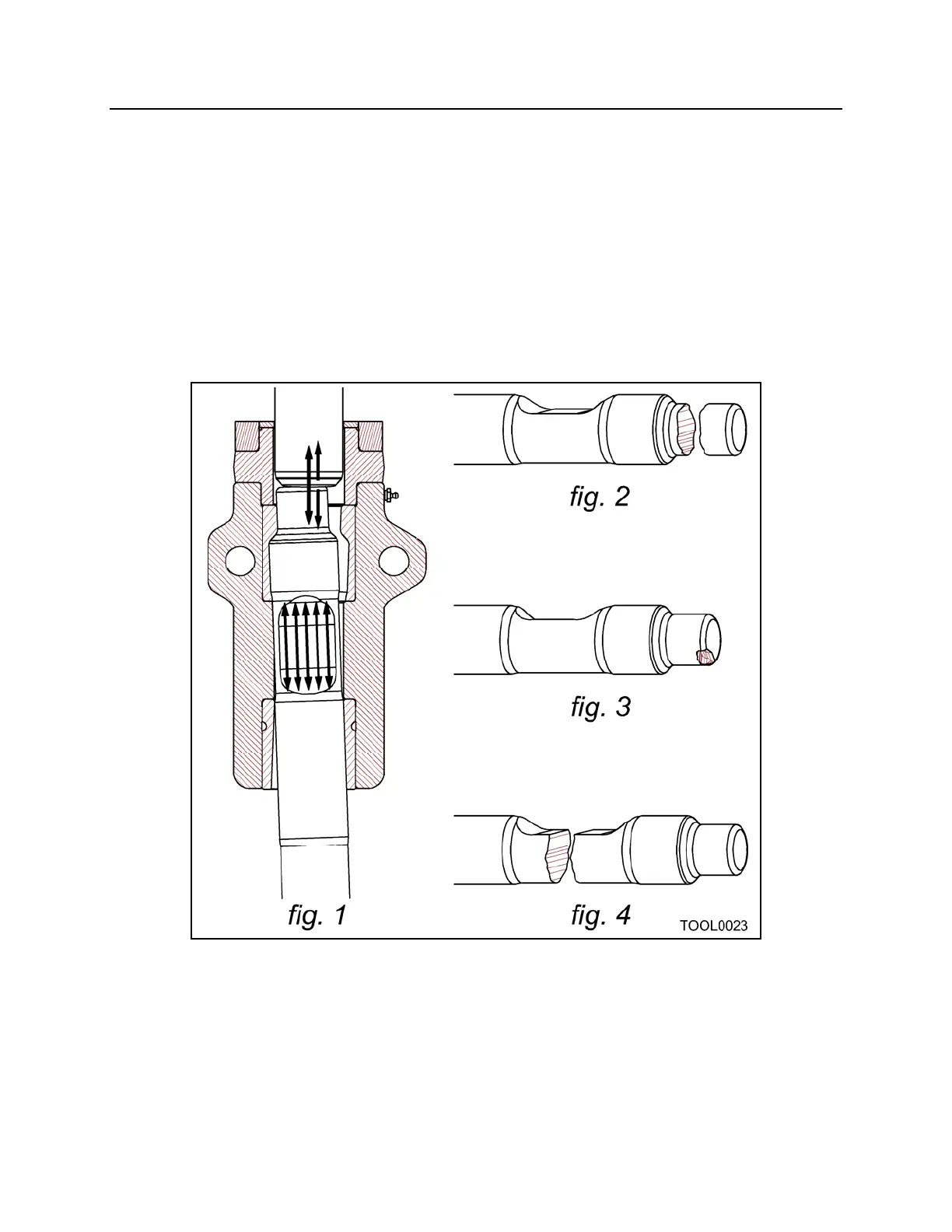

TOOL BREAKAGE DUE TO EXCESSIVE WEAR OF THE TOOL

HOLDER BUSHINGS

If the hydraulic hammer is used with tool holder bushings worn beyond specifications,

the tool will be at an excessive angle to the piston at the moment of impact. The entire

force of the piston is concentrated in a small area of the impact head of the tool (Fig. 1).

This results in the impact head being chipped or broken (Fig. 2 & 3). With the tool at an

angle, and in excessive side loading contact with the tool holder bushings, the shock

load traveling down the tool is unevenly concentrated (Fig. 1). This can result in the tool

breaking through the retaining pin slot (Fig. 4).

Loading...

Loading...