Cascade Instructions │ Vmax I&O Manual

Labeling - Label all wires prior to disconnecting them when servicing controls. Wiring

errors can cause improper and dangerous operation. Failure to follow instructions may

result in property damage or personal injury.

Continuity - Before connecting the line voltage wiring, perform a continuity check

between all wires and ground to make sure that there are no electrical leaks that could

blow a fuse or damage electrical components. Also check the polarity of the line and

neutral wires. Line must measure 120VAC to ground; neutral must measure zero. Failure

to follow instructions may damage the unit.

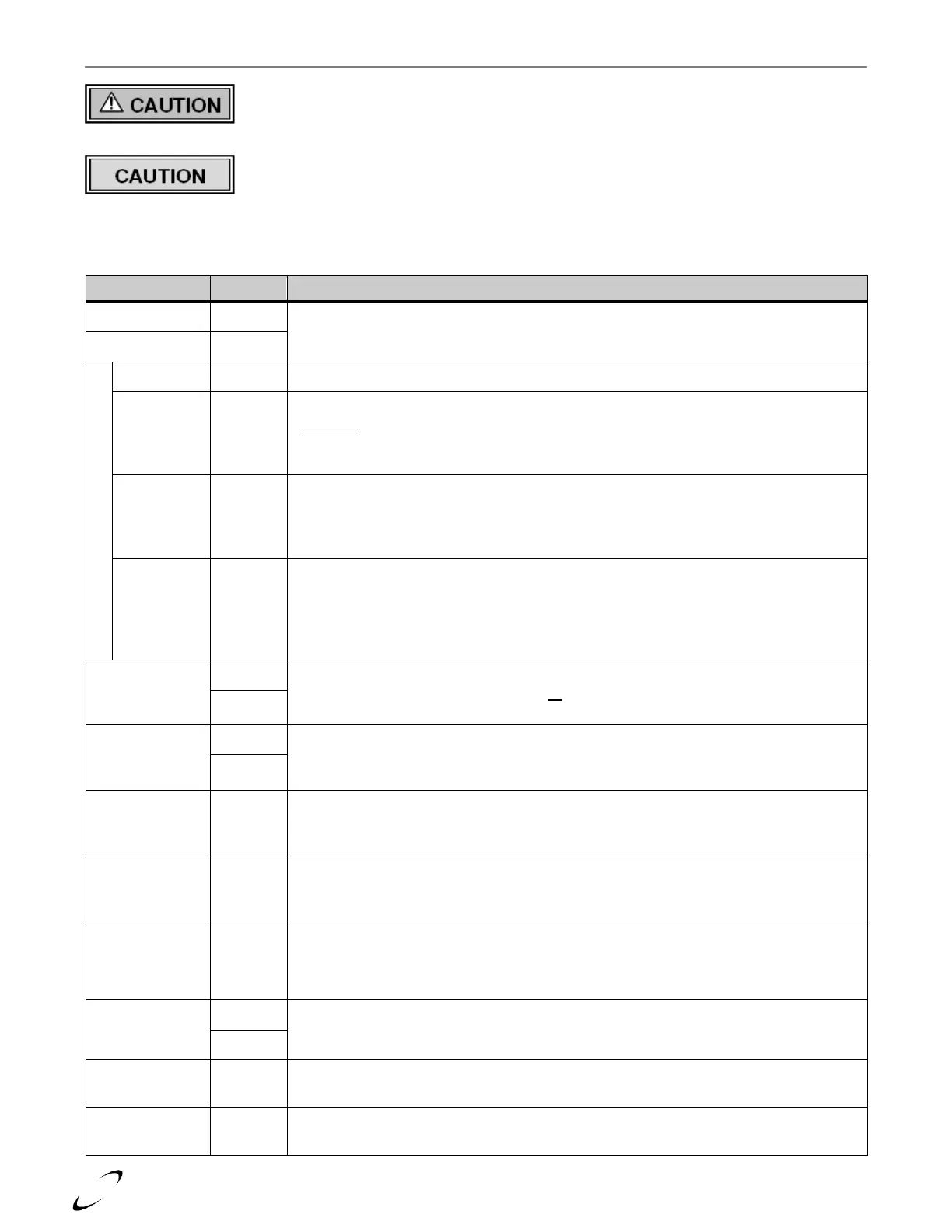

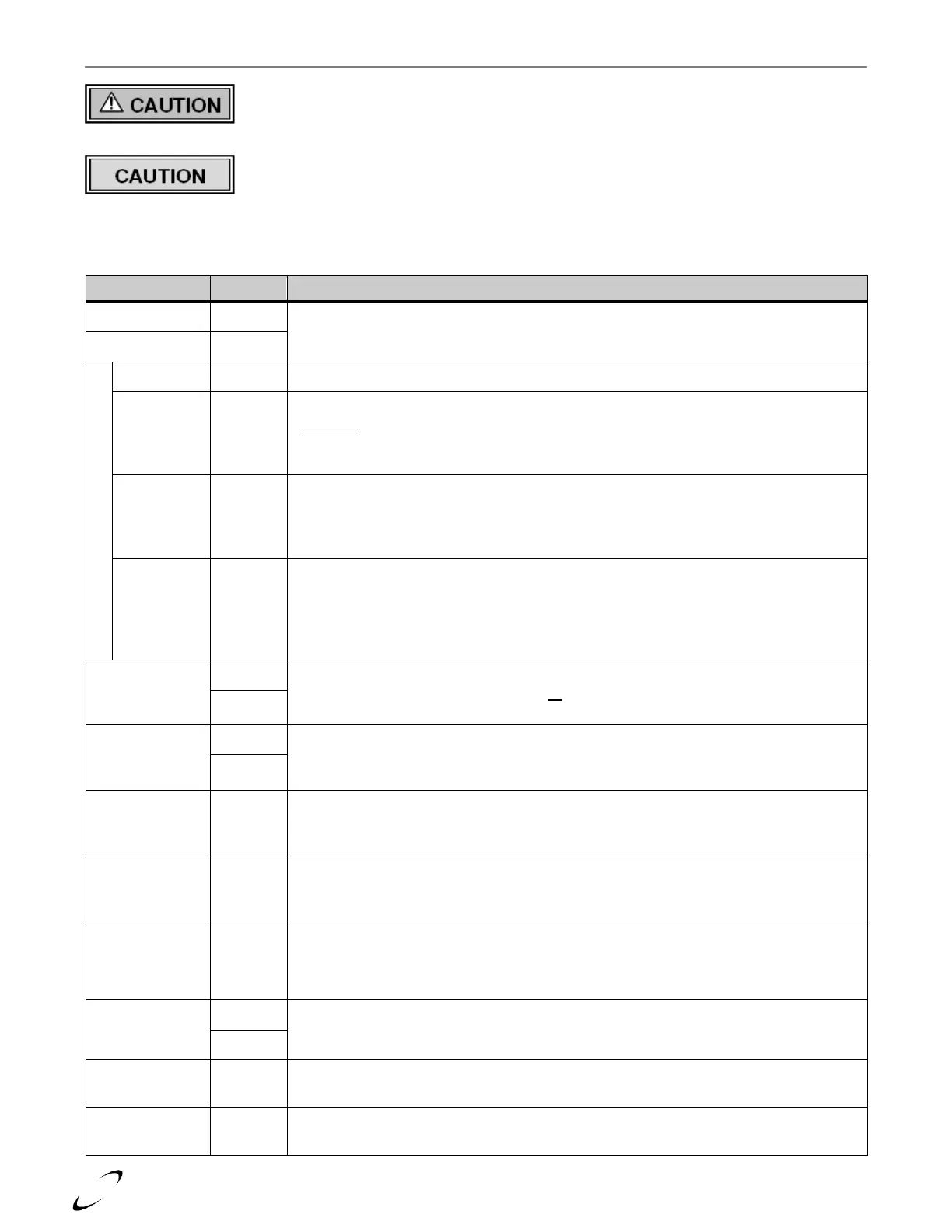

Table 12-1 Field Connections

Argus Link Communication – used to cascade up to 16 boilers, also for connection to

USB interface for PC-connection and BMS Modbus/Expansion Interface Module.

Sensor Common – Common port for field inputs SYSTEM, OUTDOOR and DHW.

System Temperature Sensor (Optional) – Wire to terminals 3 and 4 of the main boiler in

a cascade. Sensor would be installed on the system supply pipe feeding the Central

Heating system to allow accurate control of system temperature. Sensor is available from

NTI, p/n: 84010.

Outdoor Temperature Sensor – A wall mountable OD Sensor is included with each

boiler; connect to terminals 3 and 5. In a cascade, the OD Sensor only needs to be

connected to the main boiler. The use of the OD Sensor is required to allow the boiler

control to automatically infer the heat load of a central heating system.

Tank Thermostat / Sensor – Connect the contacts of a DHW Tank Thermostat, or leads

of an approved DHW Tank Sensor (NTI p/n: 84632), to terminals 3 and 6. When using a

Thermostat, set DHW mode = 2 (menu setting 2-08). When using a Sensor, set DHW

mode = 1. A Tank Sensor is factory wired to terminals 3 and 6 on Vmax Plus models

(VM110P and VM153P). See Section 17.0 for more details.

24VAC Room Thermostat Input – Connect central heat demand switch (room

thermostats or zone control end switch), or “nighttime setback” / “time of day” switch to

terminals 7 and 8. Switch must be an isolated end switch.

120VAC Safety Limit Circuit (Factory jumpered) – wire the output contacts of any

optional external limit device (i.e. LWCO) in series with terminals 9 and 10. Note: if using

an external limit device, the factory jumper must be removed.

120VAC output to the DHW circulator; powered during a demand for DHW. Total load

of DHW PUMP and BOILER PUMP must not exceed 2.6Amps. Not applicable for Vmax

Plus models (VM110P and VM153P).

120VAC output to the Central Heating circulator; powered during a demand for Central

Heat. Total load of CH PUMP and BOILER PUMP must not exceed 2.6Amps. Note: the

VM110 internal pump is wired to this output.

120VAC output to the main boiler circulator; powered during all demands. Total load of

BOILER PUMP and CH PUMP (or DHW PUMP) must not exceed 2.6Amps. Note: the

internal pump of models VM110P, VM153 and VM153P is factory wired to this output.

Location for connecting neutral of the power supply and all circulators.

Location for connecting line voltage of the power supply. Note; most installation codes

require the installation of a service switch to break line voltage to the appliance.

Location for connecting earth ground and for grounding all circulators.

Loading...

Loading...