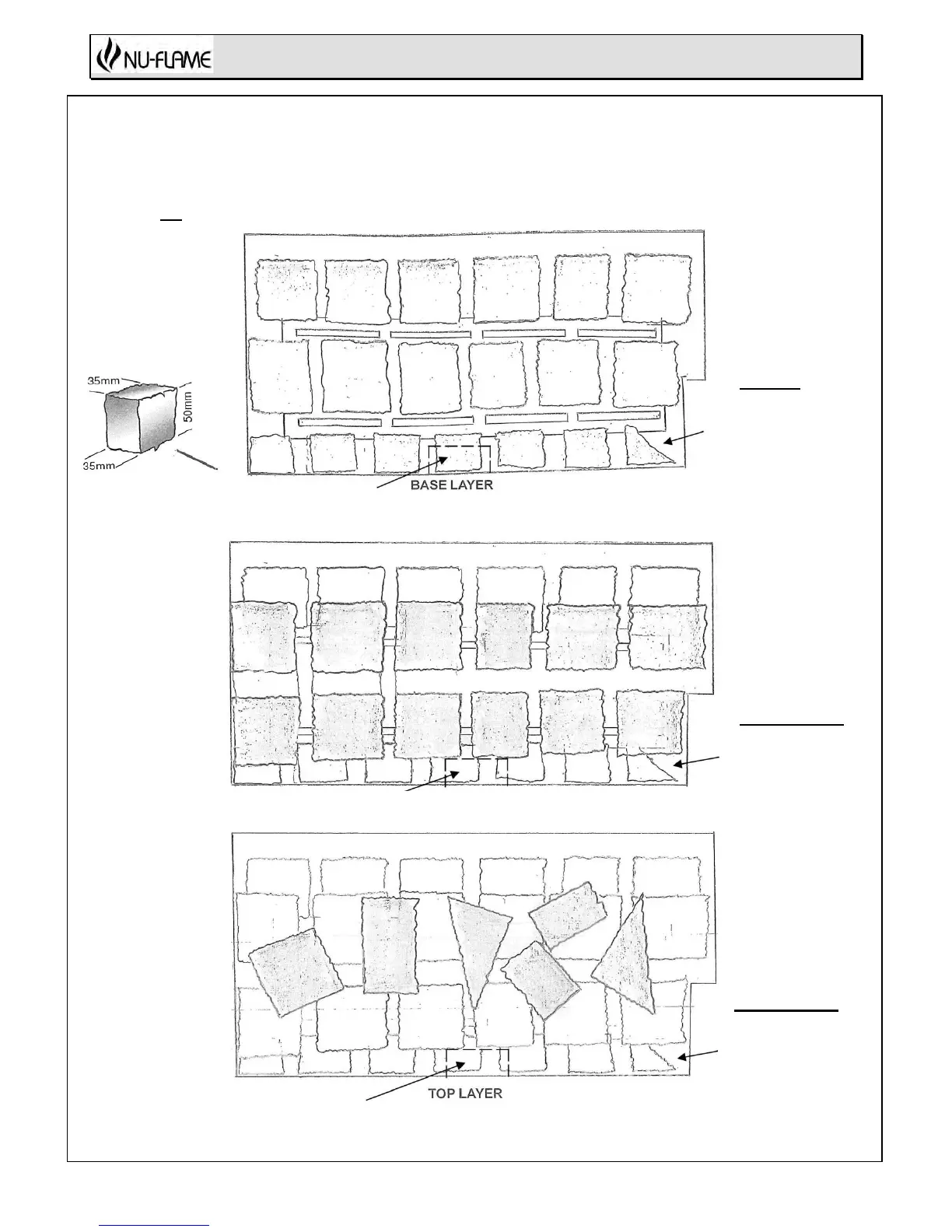

LAYOUT FOR SIMULATED COALS

Due to the many pan sizes and shapes there is not an exact pattern and these coal layouts are intended as a guide to illustrate

the general principles. It is important to leave spaces of 15mm - 20mm between the simulated coals to ensure good secondary

aeration. Do not overload the fire as it will spoil the appearance of the fire and cause sooting. Do not put more than 3 layers of

simulated coals on any fire. The small simulated coals are laid along the front of the fire and the large simulated coals above and

behind, as shown on the typical layout. Depending on the size of the fire it might not be necessary to use all the simulated coals

supplied. Do not add further simulated coal.

For the alternative central pilot cut out positions the centre coal must be dispensed with to ensure the pilot cut out is clear. It should be used instead of the pilot coal which

should then be discarded. Do not cover any part of the gas outlet slots with the base layer of simulated coals.

SECOND LAYER

For the alternative central pilot cut out position the centre coal must be dispensed with to ensure the pilot cut out is clear. It should be used instead of the pilot coal which

should then be discarded.

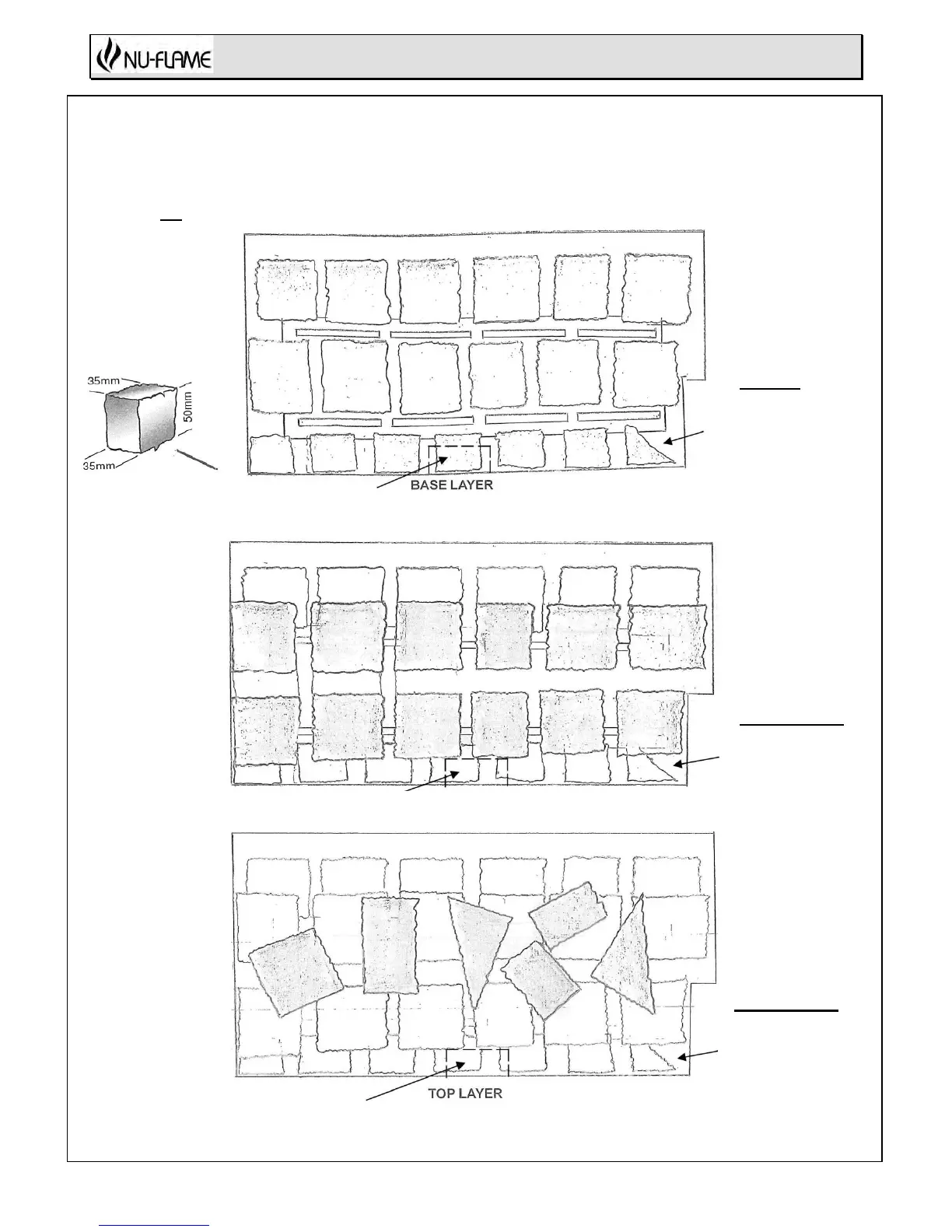

For the alternative central pilot cut out position the centre coal must be dispensed with to ensure the pilot cut out is cle ar. It should be used instead of the pilot coal which

should then be discarded.

The dressing coal set gives a random look to the top layer but it is important to keep at least a 20mm gap between these coals.

Loading...

Loading...