21

GB

COMPONENTS AND CONTROLS (PIC. 1)

OPERATING INSTRUCTIONS (PICS.2&3)

Keep guards in place and in good working order at all times to

avoidseriousaccidents.

Supportlargepanelsasshown in(Pic.2)tominimizetherisk

ofbladepinchingandkickback.Pic.3showsthewrongwayto

cut large pieces of wood, cutting in this way will cause serious

injurytotheoperator.

Whencutting, the saw should rest on the larger piece of the

materialandthesmallerpiececutoff.

Use a rip fence at all times, this will help to prevent side pressure

beingexertedonthebladeandwillalsogiveastraightercut.

GUARDING AGAINST KICK BACK (PIC.4)

Kick back occurs when the saw stalls rapidly and is driven back

towardstheoperator.Toavoidkickbackkeepbladessharpand

alwayssupportlargeworkpiecescorrectly.Releasetheswitch

immediatelyifbladebindsorifthecircularsawstalls.

Do not remove the saw from a work piece while the blade is

still moving. Never place your hands or fingers behind or in

frontofthesaw(Pic4).Ifkickbackoccurs,thesawcouldjump

backwardsoveryourhand,possiblycausingsevereinjury.

Alwayslowerguardwiththeretaininghandle.Beforecuttingbe

surethatthedepthandbeveladjustmentsaretight.

Use only the correct blades for your power tool with the correct

boresize.

Neverusedefectiveorincorrectbladewashersorbolts.

Avoidcuttingnailsbyinspectingtheworkpiece,removeallnails

fromtheworkpiecebeforecutting.

Operatewiththecorrecthandandworkpiecesupport.

WARNING!

It is important to support the work piece properly and to hold the

saw firmly to prevent loss of control which could cause personal

injury.

Pic.5illustratesthecorrecthandpositionstosupportofthesaw

safely.

Place the wider portion of the saw base on that part of the work

piece which is solidly supported, not on the section that will fall

offwhen thecutismade. If the workpieceisshort or small,

clampittoasuitablesupport.

DO NOT TRY TO HOLD SHORT PIECES BY HAND!

Pic.6illustratesthecorrectwaytocut offtheend ofa board.

Pic.7showsthewrongwaytocutofftheendofaboard.

Never attempt to saw with the Circular Saw held upside down

inavice(Pic.8)thisisextremelydangerousandcanleadtoa

seriousaccident.

Before setting the tool down after completing a cut, be sure

that the lower guard has closed and the blade has come to a

completestop.

ADJUSTMENTS (PICS. 9 TO 12)

DEPTH OF CUT AT 90° (PIC.9)

TheCircularSawhasanadjustabledepthofcut.Toadjustthe

depth of cut slacken the lever located on the side of the machine

(Pic.9).Measurethedepthrequiredfromthebaseplatetothe

highest point of the blade or use the depth gauge on the fixed

guard.(Pic.10).

ANGLE OF CUT 0-45° (PIC.11)

Locatedatthefrontofthemachineisthe0-45°lockinglever

(Pic.11). Slacken the lever and the base plate assembly will

rotate between 0-45°. Set the desired cutting angle by using

degree scale at the front of the machine and tighten the locking

lever.

Atthefrontofthebaseplatetherearetwonotchesmarked90°

and45°.Thesenotchesareaguidetoindicatethepositionof

thebladeinrelationtothecutbeingmadeinthematerial.

PARALLEL CUTTING (PIC.12)

This machine is supplied with a parallel cutting guide. This

cutting guide is fitted to the front of the machine and secured

withthelockingknob(Pic.12).

CHANGING THE BLADE (PICS. 13 TO 16)

CAUTION:AlwaysensurethattheCircularSawisdisconnected

from the mains supply before carrying out any maintenance or

adjustments.

The blade is extremely sharp and care must be observed when

handling.

Caution must be observed as the blade guard is spring loaded

and if released maycause an injury. Rotate the blade guard

into the fully open position and secure it in this position using a

screwdriverorpieceofwood.

Depress the spindle lock and using the supplied hex key,

unscrew the hex socket screw in a anti-clockwise direction.

(Pic.13-14)

CAUTION: The hex socket screw is a normal right hand

thread.

Removethehexsocketscrewandtheretainingflangenoting

whichwayroundtheretainingflangeisfitted(Pic.14).Youcan

nowremovetheblade.

NOTE: Donotdisposeofthebladeinhouse-holdwaste,recycle

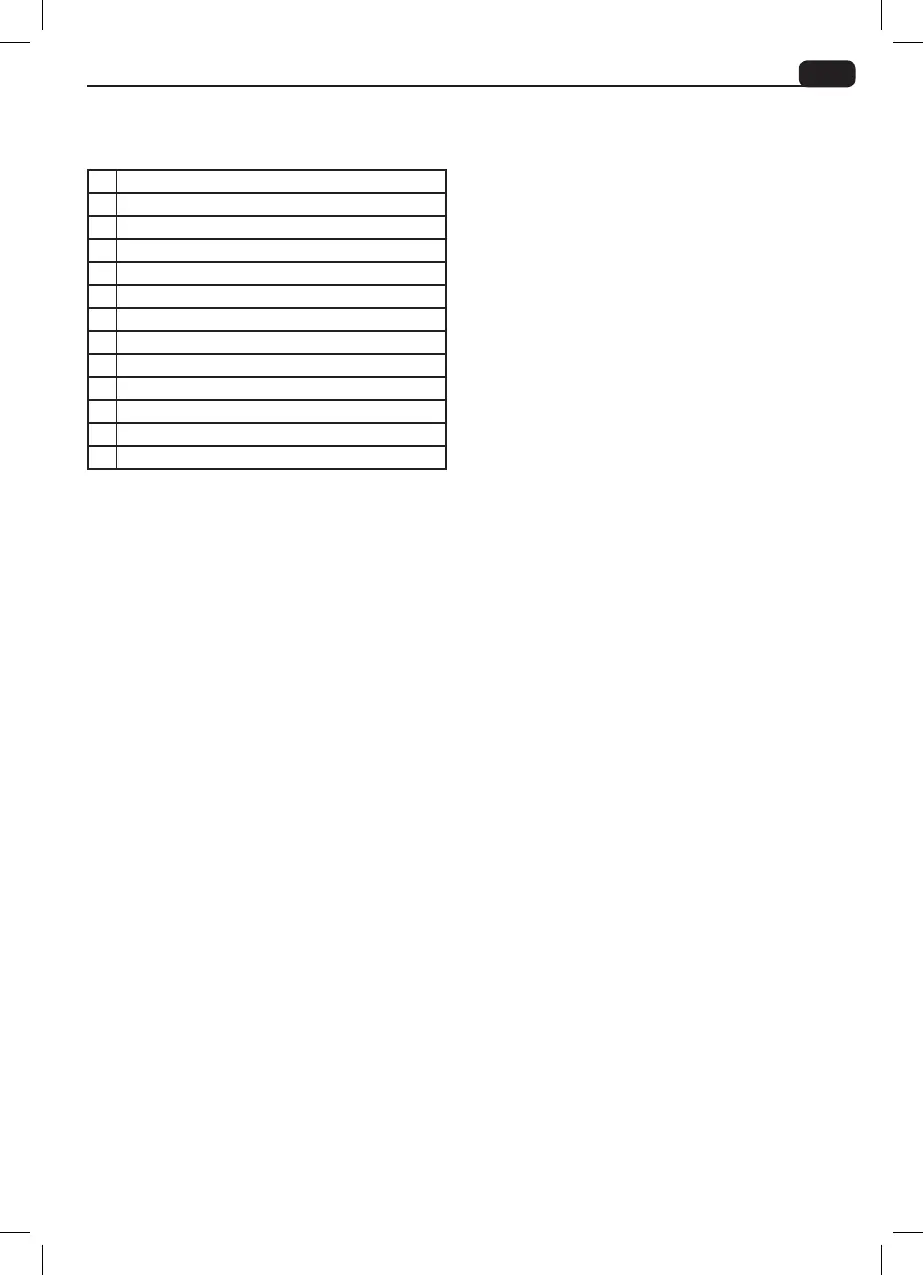

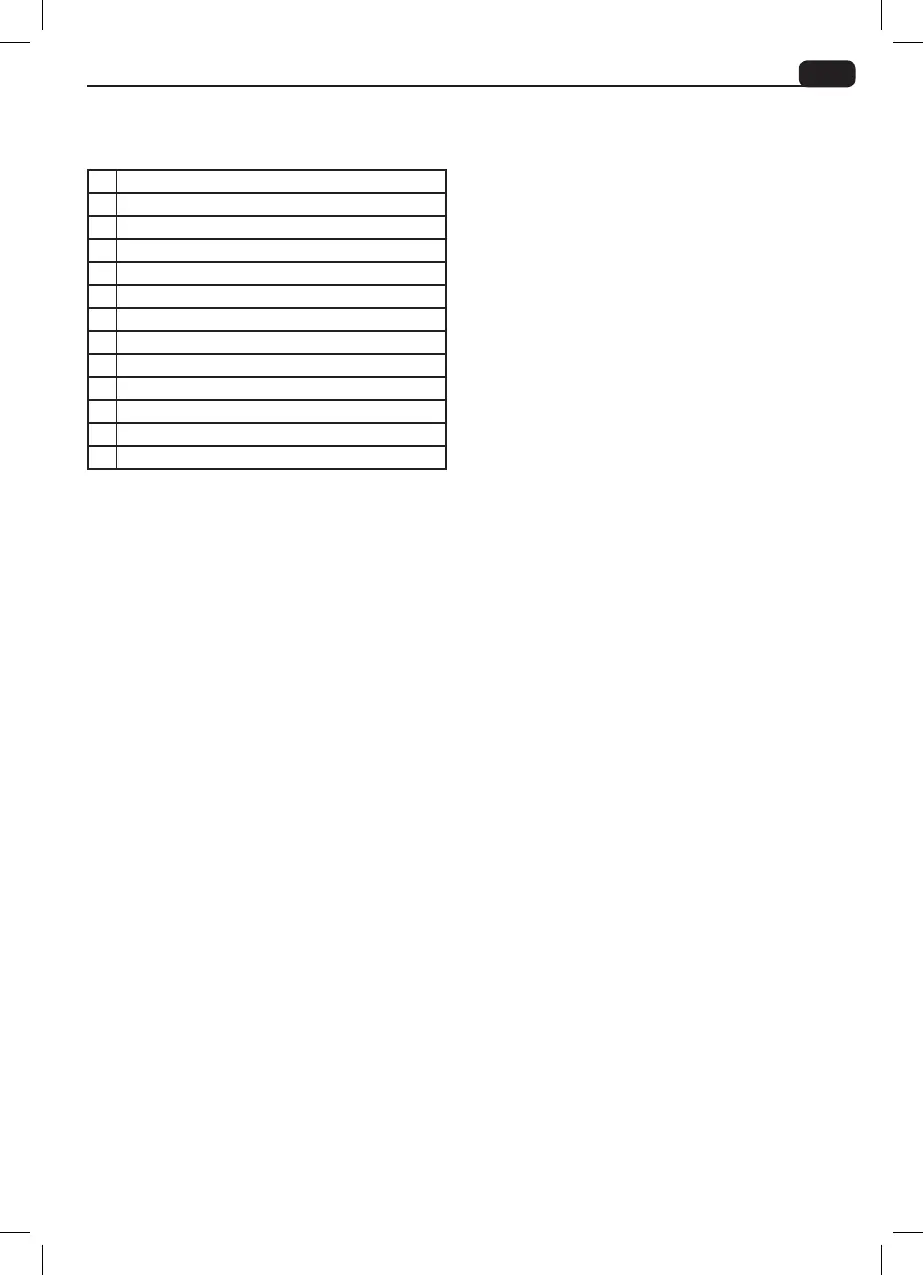

1 Hand grip incorporating on/off switch

2 Dust extraction outlet

3 Blade guard

4 Blade cover

5 Front hand grip

6 Power cable

7 Base plate locking knob

8 Tungsten carbide tipped blade

9 Blade bolt

10 Blade flange

11 Base plate

12 Blade spanner

13 Parallel guide

Loading...

Loading...