OFITE, 11302 Steeplecrest Dr., Houston, TX 77065 USA / Tel: 832-320-7300 / Fax: 713-880-9886 / www.ote.com 13

Procedure:

1. Choose the certied calibration uid using the temperature-viscosity chart

supplied with the calibration uid to cover the viscosity range of interest.

Make sure the lot number on the chart matches the lot number on the

uid container. Each lot of standard uid is individually certied. The

viscosity will normally vary slightly from lot to lot.

2. Clean and dry the viscometer bob, sleeve, and cup. Place the viscometer

and the calibration uid side-by-side on the counter top in a room

with a reasonably constant temperature (variation of less than 5°F ±

2.5°F). Allow the viscometer and the uid to stand at least two hours to

equilibrate.

3. Operate the viscometer in air for two to four minutes to loosen up the

bearings and gears. Observe the rotor sleeve for excessive wobbling and

replace if necessary.

4. Fill the cup to the scribed line with calibration uid and place it on the

viscometer stage. Move the stage upward until the uid level is to the ll

line on the sleeve.

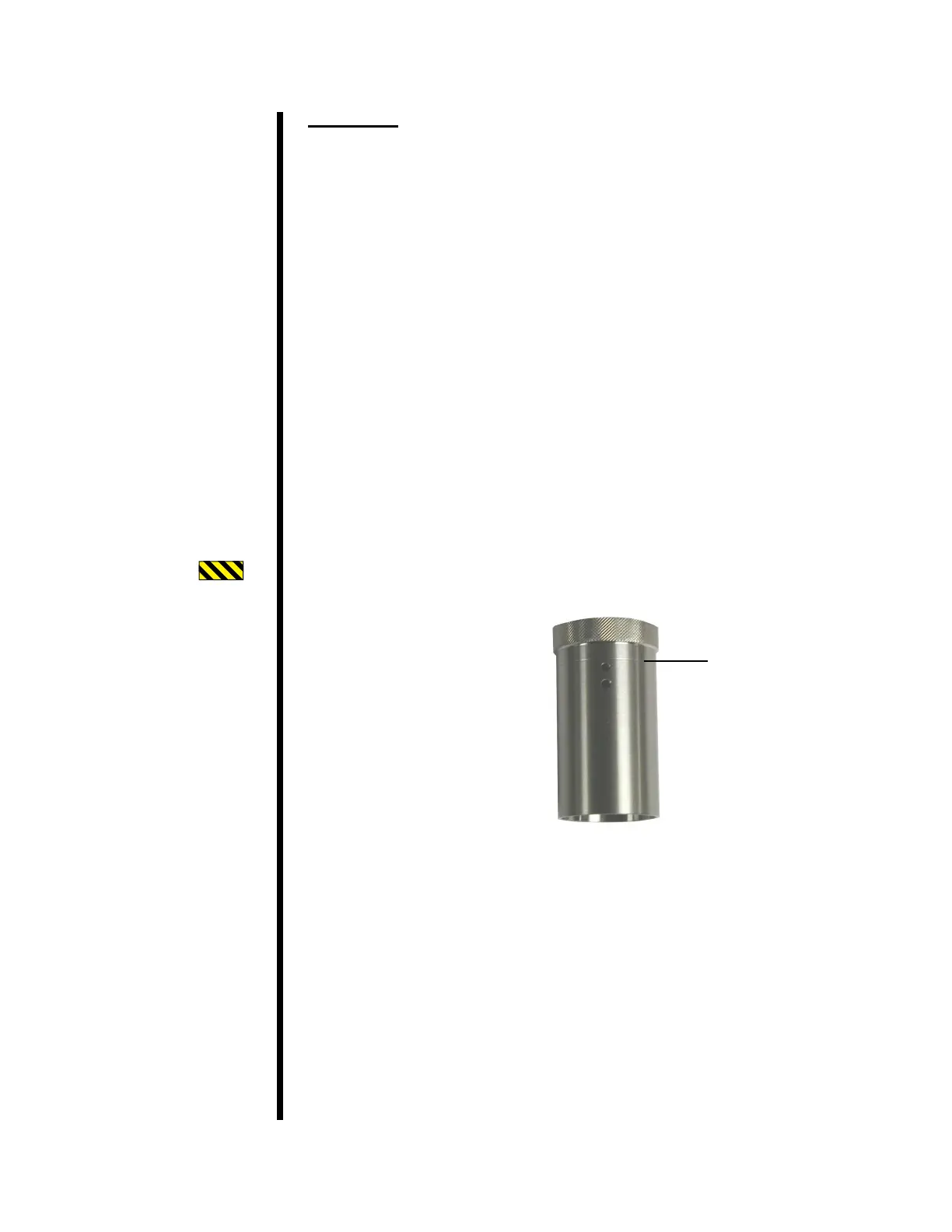

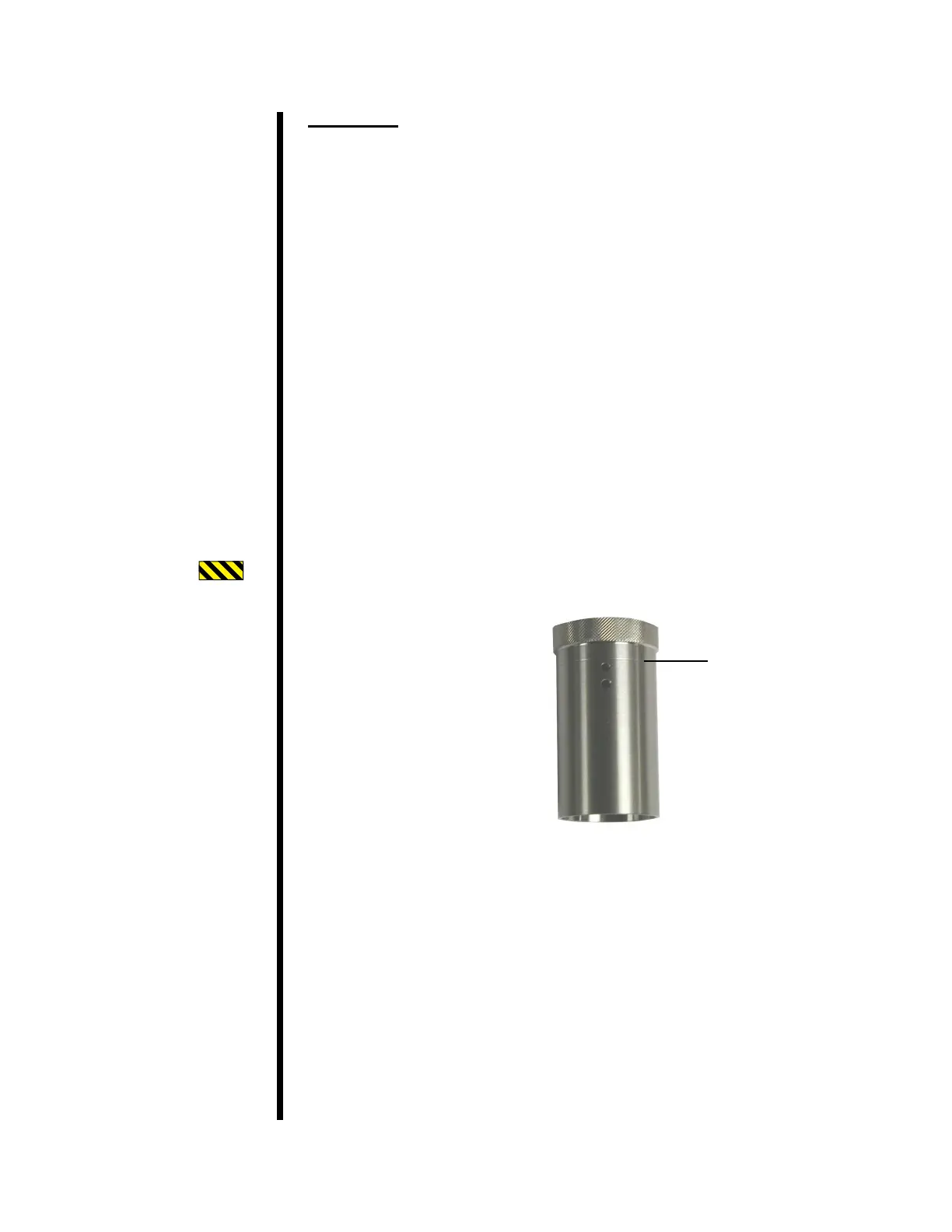

Never immerse the sleeve in uids above the ll line.

Fill Line

Viscometer Sleeve

5. Place a thermometer capable of ± 0.2°F (0.1°C) into the uid and hold

or tape it in place to prevent breakage. Operate the viscometer at a low

speed setting until the thermometer reading becomes stable to within ±

0.2°F (0.1°C) per 30 seconds. Note and record the temperature reading.

6. Once the temperature has stabilized, operate the viscometer at 600 RPM

and then at 300 RPM. Note and record the dial readings to the nearest

0.5 dial unit.

Loading...

Loading...