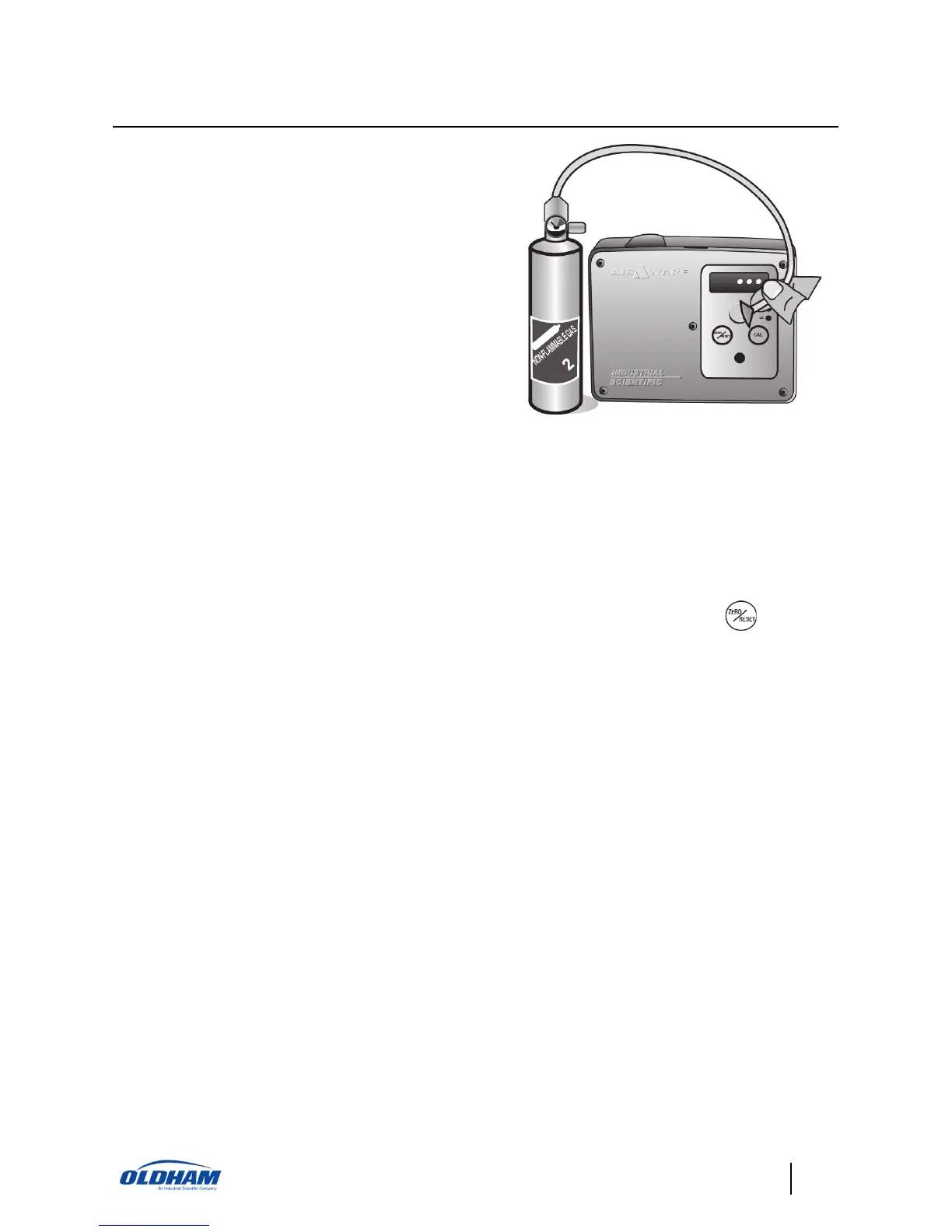

Zeroing an AirAware is the act of setting

the instrument to read either 000 ppm or

00.0 ppm (20.9 for oxygen) in a

gas/hazard-free environment. The

atmosphere must be clean and free from

the target gas during the zeroing process.

If through ventilation and other measures

it is impossible to entirely remove the

target gas from your facility, bottled

“zero” gas should be applied to the

instrument.

Connect the zero gas bottle, regulator,

and tubing to the calibration adapter.

Connect adapter to sensor opening and

open regulator. Allow zero gas to flow for

a minimum of 2 minutes.

007

With the “zero” gas still flowing to the sensor, press and hold the

key for

a total of 10 seconds. During the first 5 seconds the normal screen is still

displayed. During the next 5 seconds, the text or numeric display flashes once

per second. If the key is still held after the full 10 seconds the word “ZERO” is

displayed.

A flashing decimal point on the lower right corner of the display will appear for 3 minutes after start-up,

calibration, bump, or programming. This is an indicator that the 4-20 mA signal is locked at 3 mA and that all

alarm functions are disabled. Once this flashing indicator clears, all functions will return to normal.

Release the key and the zeroing process begins. At the end of the zero process,

the word "PASS" or "FAIL" is displayed for 5 seconds along with a .25

second audible beep, after which time the unit reverts to the normal reading

screen. An oxygen sensor will always be zeroed to 20.9%, regardless of what

the span gas is set to, and no span reserve is shown for oxygen during zeroing.

If the unit displays "FAIL" try again ensuring the area is free of the target gas.

If the unit fails a second time the sensor may need to be replaced. Contact

Industrial Scientific Oldham Corporation for a replacement sensor; see page

24 for ordering information.

Loading...

Loading...