9

Program

9.1.1. Outline of Processing

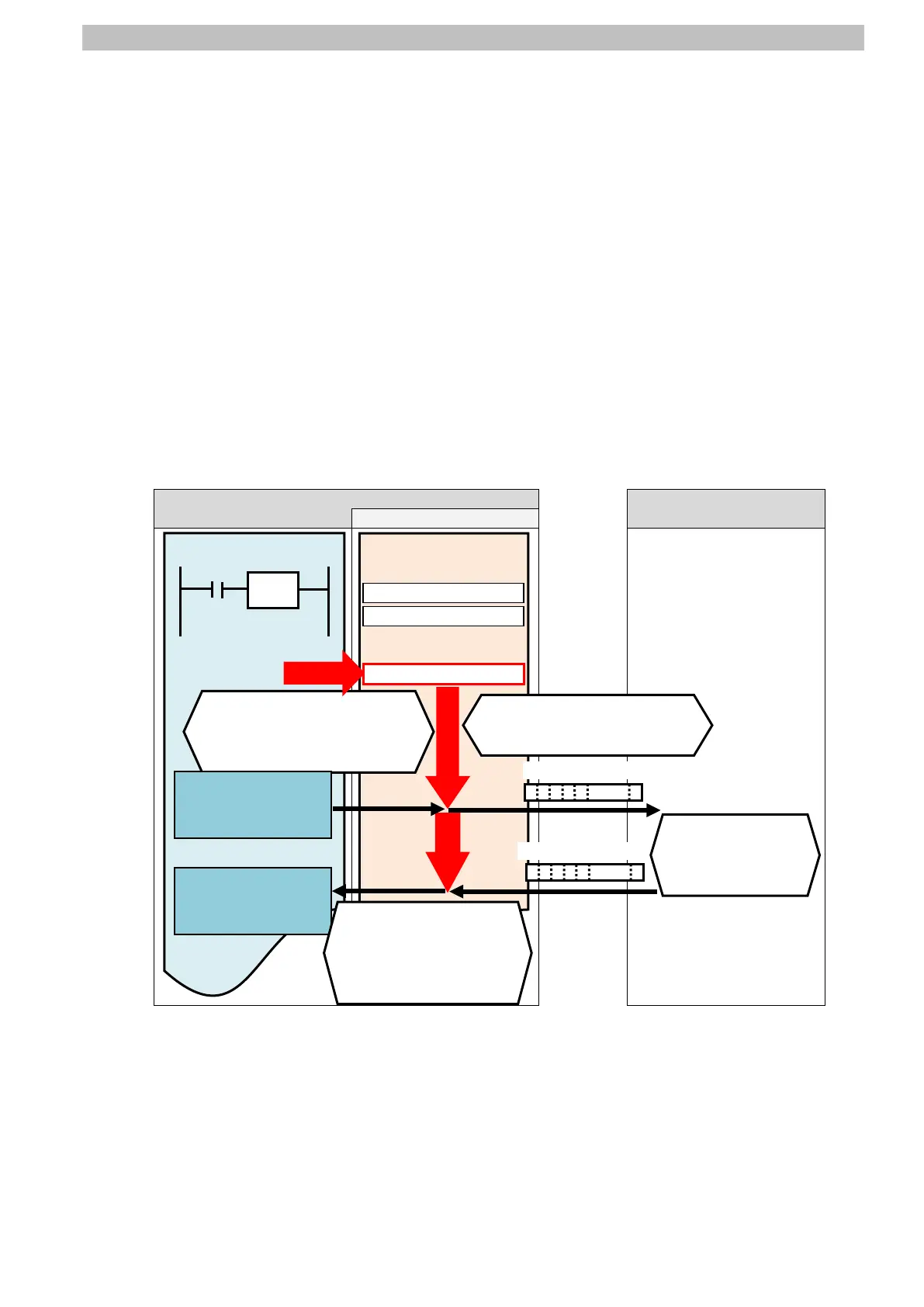

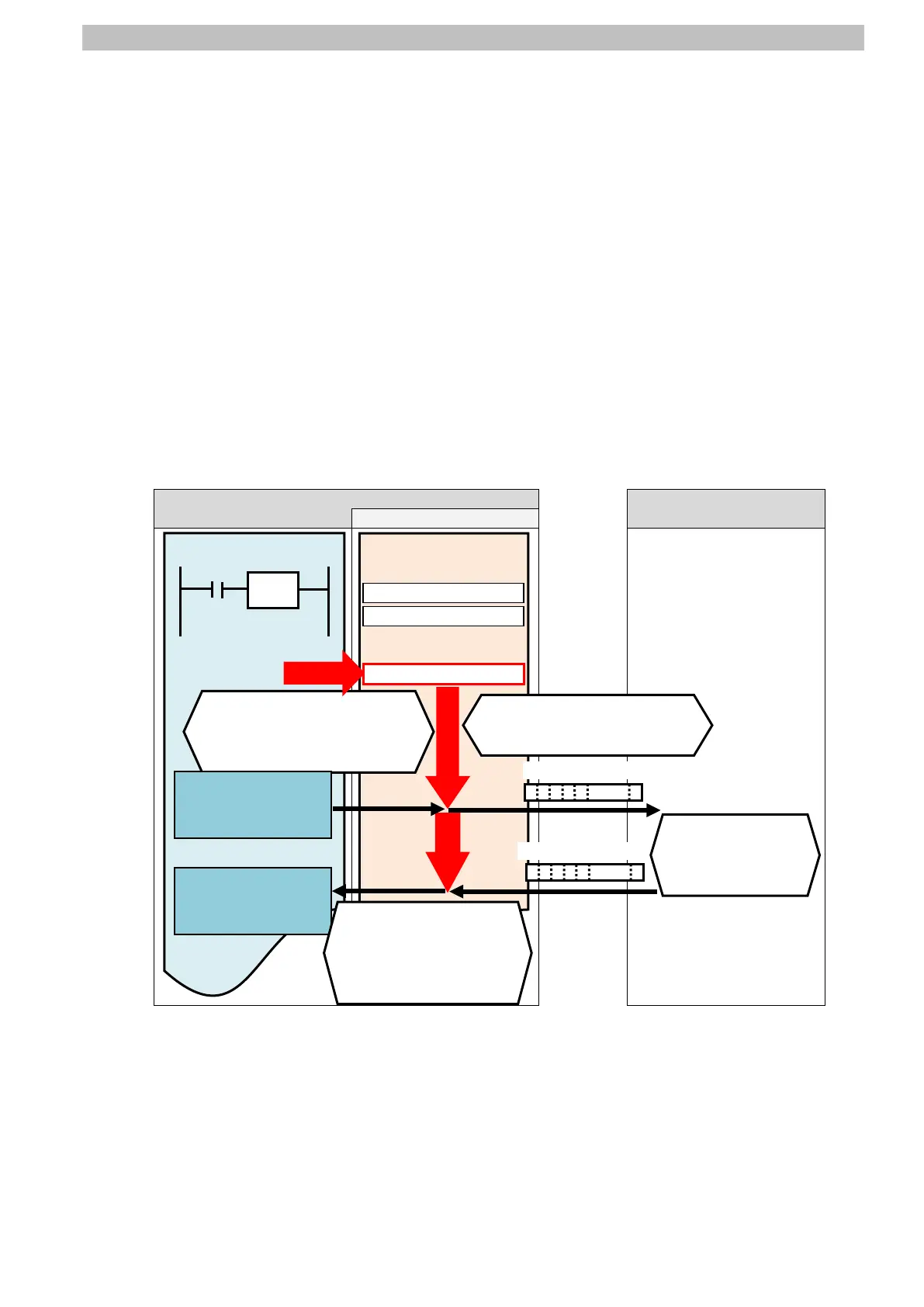

The following figure shows the data flow from when PLC (SCU) issues command data to

Destination Device using serial communications until PLC receives response data from

Destination Device.

(1)The ladder program specifies the communications sequence No. 900 and executes the

PMCR instruction.

(2) The PLC receives the response data from Sensor Controller according to receive

messages defined by the communications sequence No. 900 and stores them in the

response data storage area.

(3)The Sensor Controller executes the command by receiving the command data from PLC,

and returns response data to PLC.

(4)The PLC receives the response data from Sensor Controller according to the receive

messages defined by the communications sequence No. 900, and stores them in the

response data storage area.

RS-232C Sensor Controller

Ladder program

data.

5501 onwards

Response data

response data and

stores them in the

specified memory.

instruction.

(Specifying the sequence No.

command and

returns the

5020 onwards

Send data

Loading...

Loading...