D4N

Wiring

Wiring

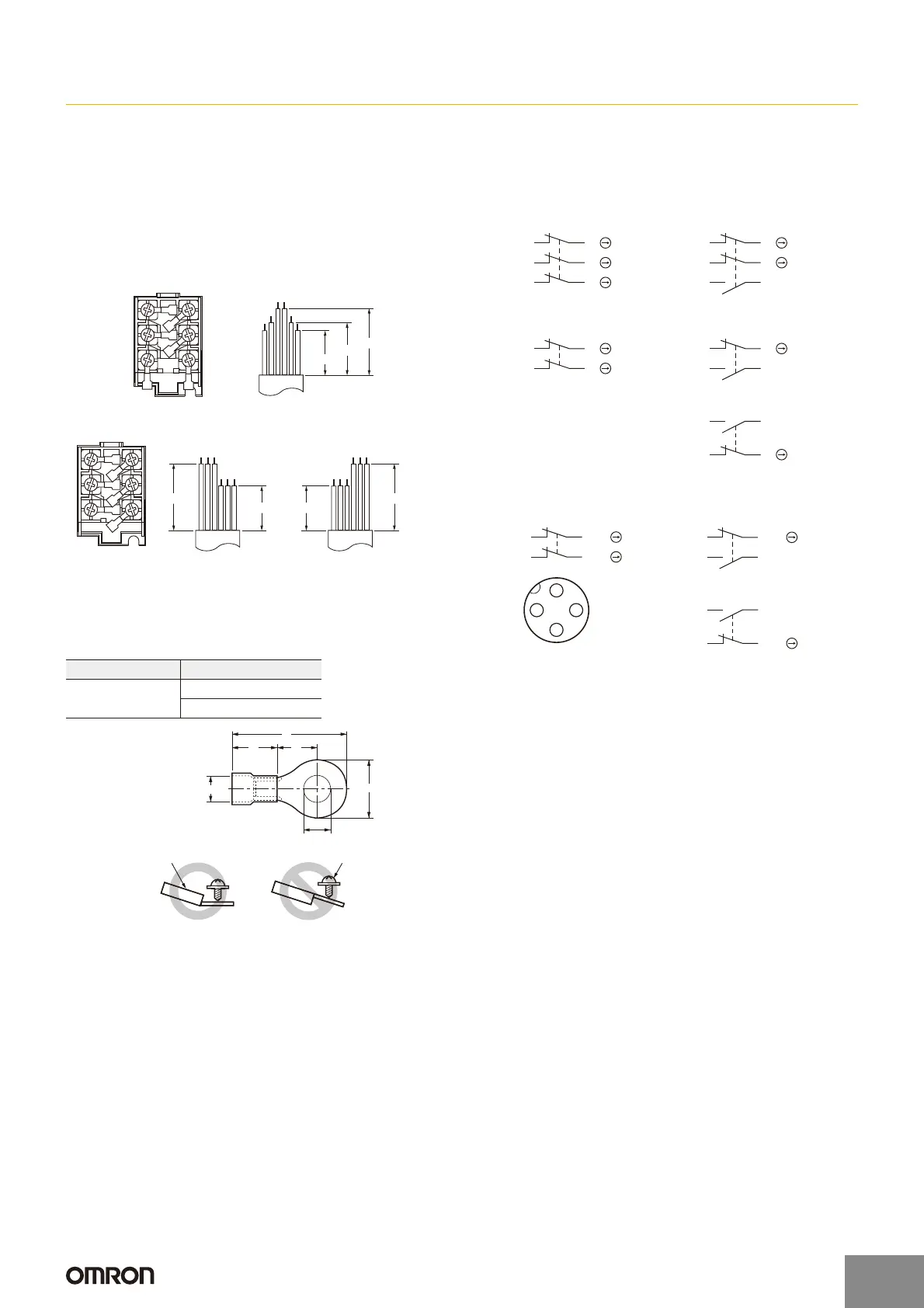

x When connecting to the terminals via insulating tube and M3.5

crimp terminals, arrange the crimp terminals as shown below so

that they do not rise up onto the case or the cover.

Applicable lead wire size: AWG20 to AWG18 (0.5 to 0.75 mm

2

).

Use lead wires of an appropriate length, as shown below. Not

doing so may result in excess length causing the cover to rise and

not fit properly.

One-conduit Type (3 Poles)

Two-conduit Type (3 Poles)

x Do not push crimp terminals into gaps in the case interior. Doing so

may cause damage or deformation of the case.

x Use crimp terminals not more than 0.5 mm in thickness. Otherwise,

they will interfere with other components inside the case.

[Reference] The crimp terminals shown below are not more than

0.5 mm thick.

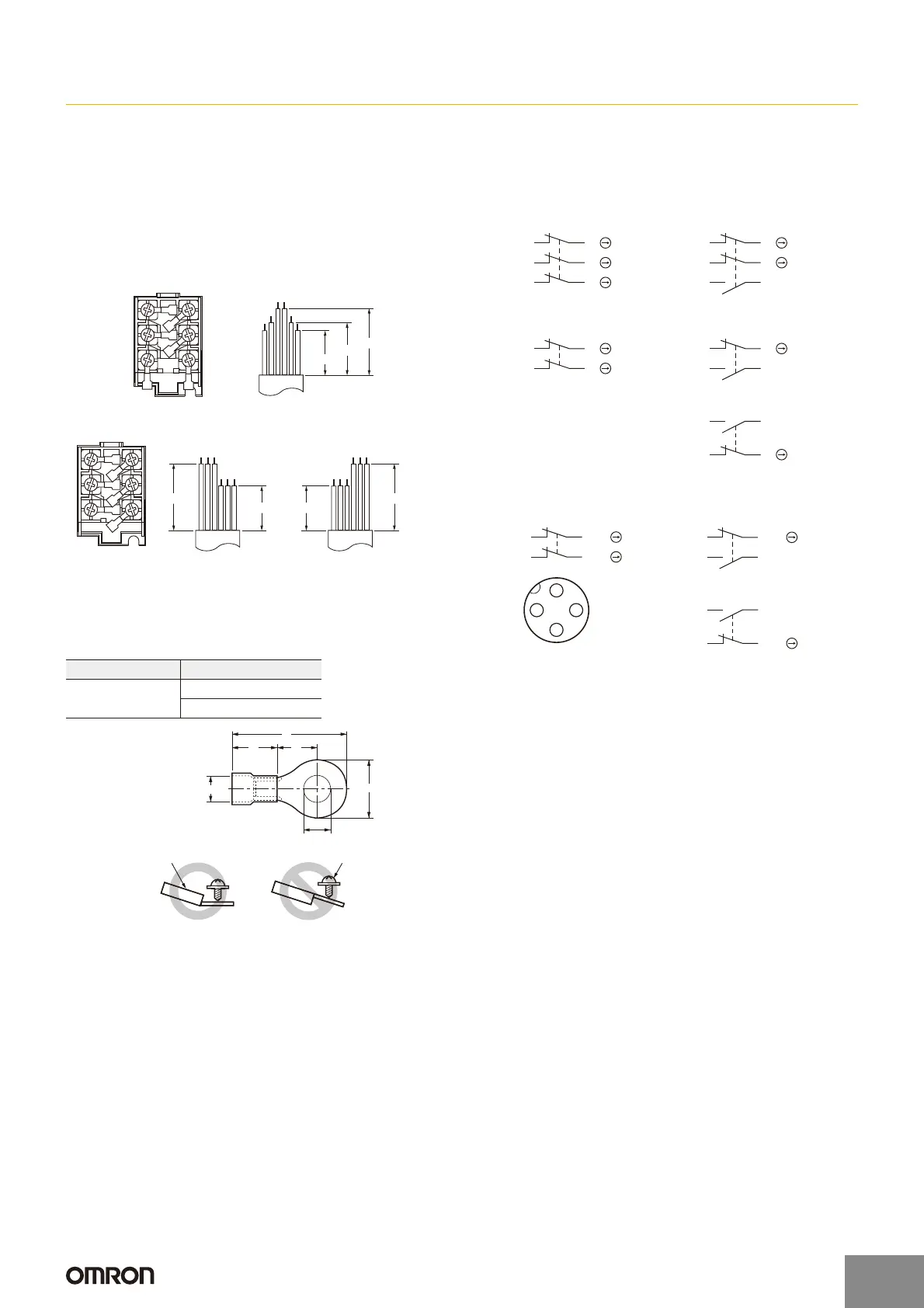

Contact Arrangement

x The contact arrangements are shown below.

Screw Terminal Type

Connector Type

x Applicable socket: XS2F (OMRON).

x Refer to the Connector Catalog for details on socket pin numbers

and lead wire colors.

Socket Tightening (Connector Type)

x Turn the socket connector screws by hand and tighten until no

space remains between the socket and the plug.

x Make sure that the socket connector is tightened securely.

Otherwise, the rated degree of protection (IP67) may not be

maintained and vibration may loosen the socket connector.

Conduit Opening

x Connect a recommended connector to the opening of the conduit

and tighten the connector to the specified torque. The case may be

damaged if an excessive tightening torque is applied.

x When using 1/2-14NPT, wind sealing tape around the joint

between the connector and conduit opening so that the enclosure

will conform to IP67.

x Use a cable with a suitable diameter for the connector.

x Attach and tighten a conduit cap to the unused conduit opening

when wiring. Tighten the conduit cap to the specified torque. The

conduit cap is provided with the Switch (2-conduit types).

Changing the Lever

The lever mounting screws can be used to set the lever position to

any position in a 360q angle at 7.5q increments. Grooves are incised

on the lever and rotary shaft that engage to prevent the lever from

slipping against the rotary shaft. The screws on adjustable roller lever

models can also loosened to change the length of the lever.

Remove the screws from the front of the lever before mounting the

lever in reverse (front/back), and set the level so that operation will be

completed before exceeding a range of 180q on the horizontal.

Manufacturer Type

J.S.T. Mfg. Co.

FN0.5-3.7 (F Type)

N0.5-3.7 (Straight Type)

2221

3433

12

11

A

A

C

E

B

D

F

C

E

B

D

F

28 mm

Tolerance ±2 mm

33 mm

42 mm

2221

3433

12

11

A

C

E

B

D

F

ACE

BDF

28 mm

Tolerance ±2 mm

Left hand

42 mm

ACE

BDF

28 mm

Tolerance ±2 mm

Right hand

42 mm

L

l F

B

D dia.

dz dia.

Correct Incorrect

Terminal screw

Crimp terminal

t: 0.5 mm

dz dia.: 3.7 mm

D dia.: 2.9 mm

B: 6.6 mm

L: 19 mm

F: 7.7 mm

I: 8.0 mm

14

32

13

31

D4N-@D@@ (3NC)

11

21

12

22

31 32

D4N-@B@@ (2NC)

D4N-@2@@ (2NC (SNAP))

11

31

12

32

D4N-@C@@ (2NC/1NO)

D4N-@F@@ (2NC/1NO (MBB))

D4N-@A@@ (1NC/1NO)

D4N-@E@@ (1NC/1NO (MBB))

33 34

11

21

12

22

11

33

12

34

D4N-@1@@ (1NC/1NO (SNAP))

14 (4)

32 (2)

(3) 13

(1) 31

1

3

24

Pin No. (Terminal No.)

D4N-9B@@ (2NC)

D4N-92@@ (2NC (SNAP))

D4N-9A@@ (1NC/1NO)

D4N-9E@@ (1NC/1NO (MBB))

(1) 11

(3) 31

12 (2)

32 (4)

(1) 11

(3) 33

12 (2)

34 (4)

D4N-91@@ (1NC/1NO (SNAP))

http://www.ia.omron.com/

19

(c)Copyright OMRON Corporation 2007 All Rights Reserved.

Loading...

Loading...