E2AX sensors

E2A3 sensorsE2A3 sensors

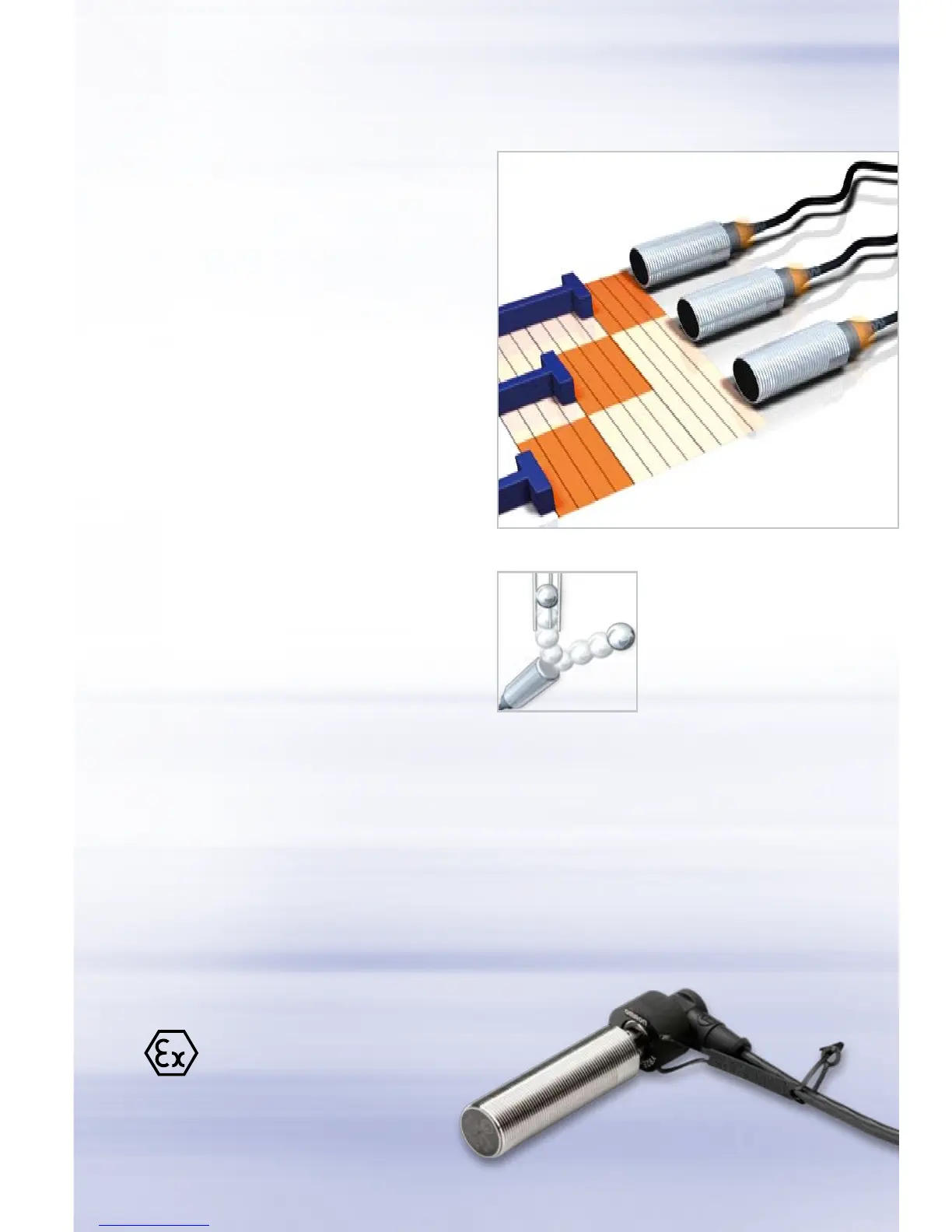

Triple sensing distance for enhanced reliability

Our E2A3 sensors offer sensing distances up to 3 times the

standard distance defined by CENELEC, greatly reducing the

likelihood of the sensing surface being struck and perhaps

damaged by moving machine parts. Thanks to the use of

optimised sensing circuitry and new sensor geometry, the

sensor is able to send a stop signal to the machine much

earlier than standard- or double-distance sensors without

any compromise to sensor performance.

E2AX sensors

Explosion protection in dusty environments

Intended for use in potentially explosive atmospheres

using substances from sawdust to flour, E2AX sensors meet

demanding regulatory requirements governing explosion

protection - including ATEX certification Group II category 3D

(94/9/EG Appendix VIII).

To minimise the possibility of ignition from exposed circuitry,

their robust, hermetic housings are designed to withstand

mechanical shock without fracture, and the sensors also

feature a special retaining bracket to prevent the cable being

detached during operation.

ATEX certification, which is done by an independent

notified body, relates not just to the products but also to

the production facility which must provide a regime of full

traceability in the event that a malfunction occurs leading

to an explosion.

E2AX

The Ball Drop Test is part of the

ATEX approval ensuring high

mechanical protection

of electronic parts.

Loading...

Loading...