12-28

12-4 Troubleshooting

OMNUC G5-series AC Servomotors and Servo Drives User’s Manual (with Built-in EtherCAT Communications)

12

Troubleshooting and Maintenance

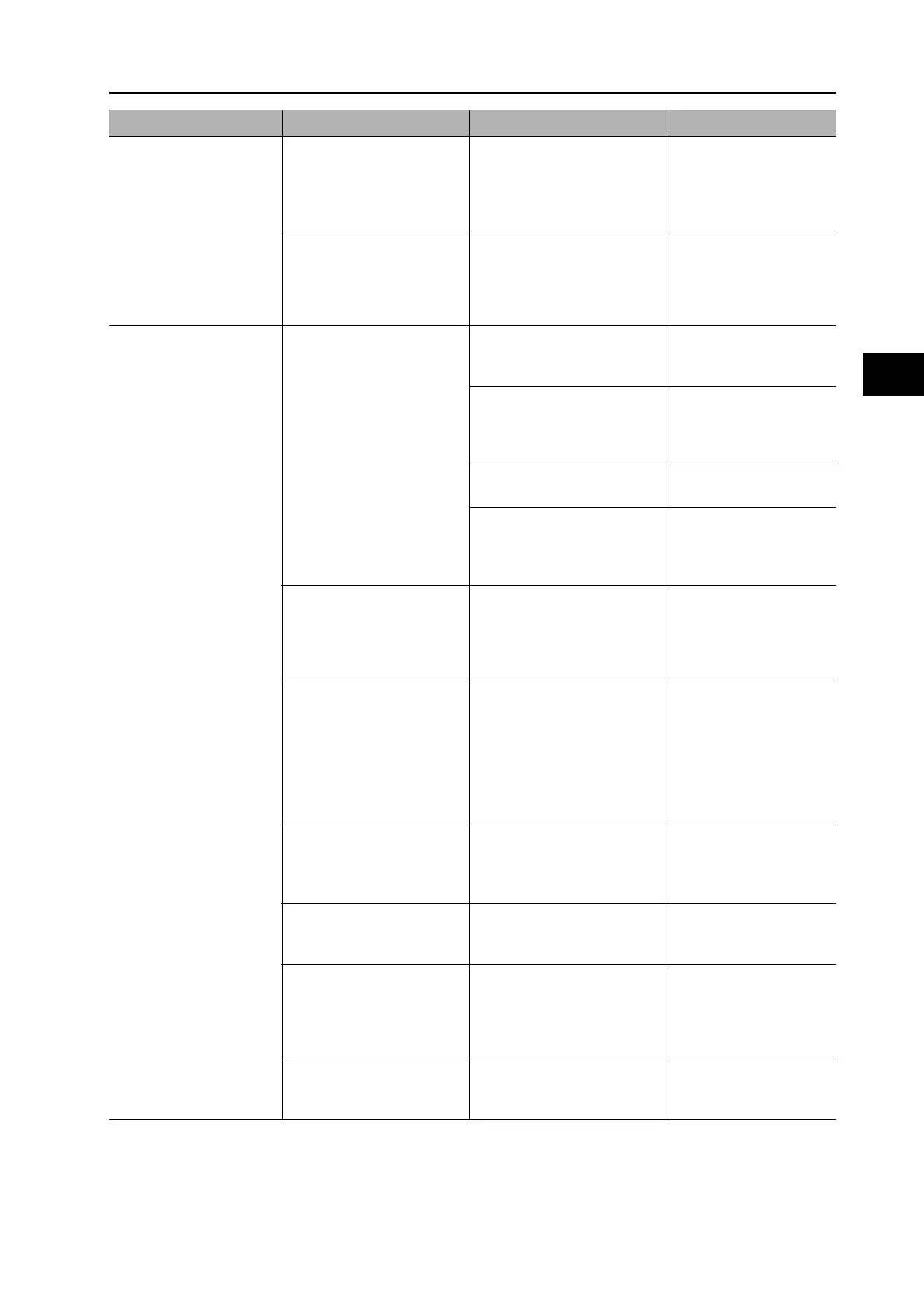

The Servomotor does not

stop or is hard to stop

even if the servo is turned

OFF while the

Servomotor is rotating.

The load inertia is too large. • Check the load inertia.

• Check the Servomotor

rotation speed.

• The dynamic brake

resistance is disconnected.

• Review the load inertia.

• Replace the

Servomotor and Servo

Drive with proper ones.

The dynamic brake is

disabled.

Check if the dynamic brake is

disabled or broken.

• Enable the dynamic

brake, if it is disabled.

• Replace the brake if it is

broken or if the resistor

is disconnected.

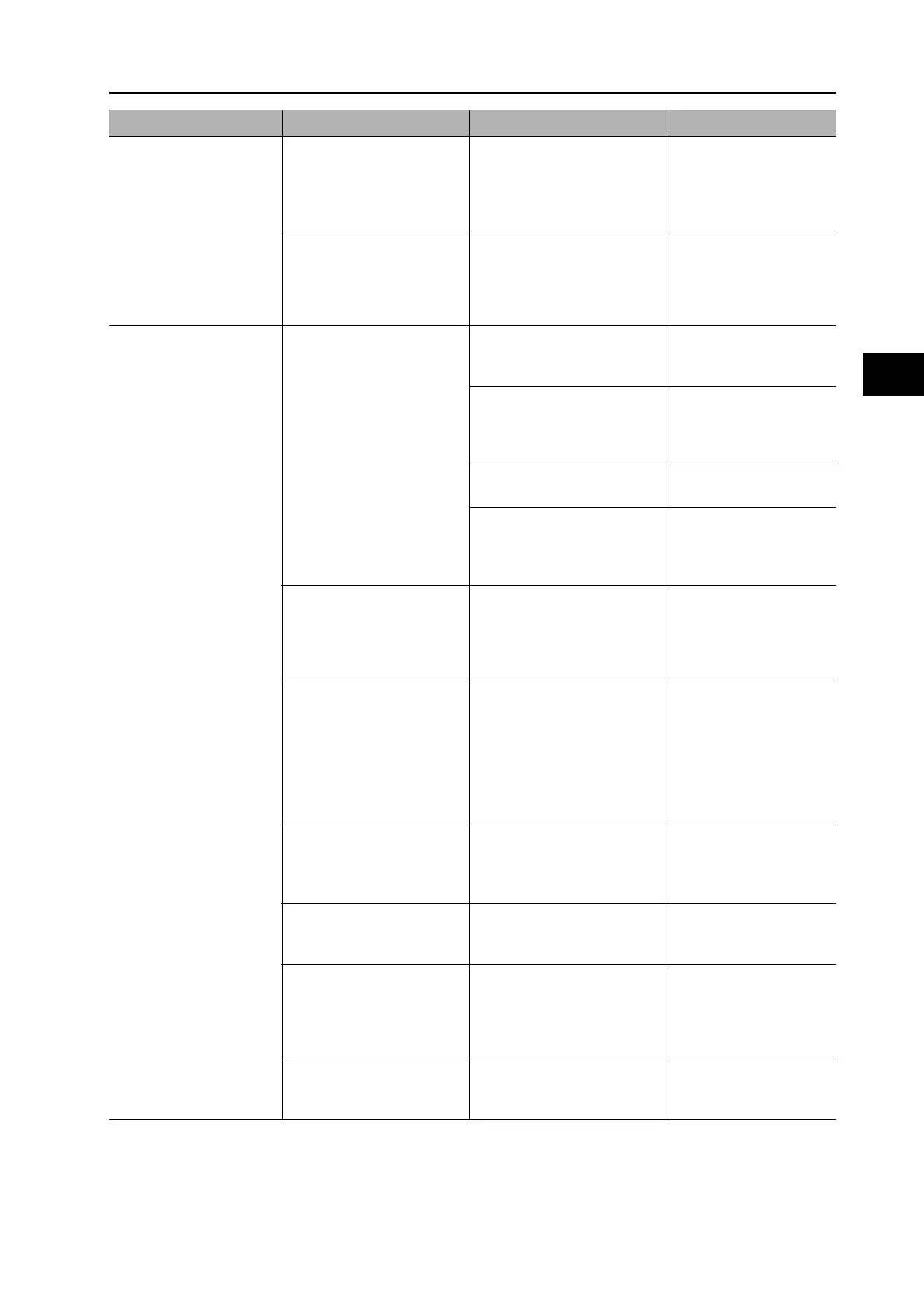

The Servomotor or the

load generates abnormal

noise or vibration.

Vibration occurs due to

improper mechanical

installation.

Check to see if the

Servomotor's mounting

screws are loose.

Retighten the mounting

screws.

Check the load for

eccentricity.

Eliminate the

eccentricity. It results in

torque fluctuation and

noise.

Check to see if the coupling

with the load is unbalanced.

Balance the rotation.

Check to see if the decelerator

is generating any abnormal

noise.

Check the decelerator

specifications. Check the

decelerator for

malfunctions.

Vibration occurs due to low

mechanical rigidity.

Check to see if the vibration

frequency is 100 Hz or lower.

If the frequency is 100 Hz

or lower, set the correct

damping frequency for

the damping filter to

eliminate the vibration.

Vibration occurs due to

machine resonance.

Check to see if the resonance

frequency is high or low.

If the resonance

frequency is high, set the

adaptive filter to eliminate

the resonance.

Alternatively, measure

the resonance frequency

and set Notch Filter 1 and

2.

There is a problem with the

bearings.

Check for noise or vibration

around the bearings.

Check to see if the

bearings are mounted

properly, and adjust them

if necessary.

The gain is wrong. − Check if manual tuning

can achieve proper

adjustment.

The Speed Feedback Filter

Time Constant 1 (3103 hex)

is wrong.

Check the set value of object

3103 hex. Normally set 0.

Return the setting to the

default value of 0.

Alternatively, set a large

value and operate the

Servomotor.

The Torque Command Filter

Time Constant 1 (3104 hex)

does not match the load.

Review the set value of object

3104 hex.

Set a larger value for

object 3104 hex to

eliminate the vibration.

Symptom Probable cause Items to check Measures

Loading...

Loading...