12-27

12-4 Troubleshooting

OMNUC G5-series AC Servomotors and Servo Drives User’s Manual (with Built-in EtherCAT Communications)

12

Troubleshooting and Maintenance

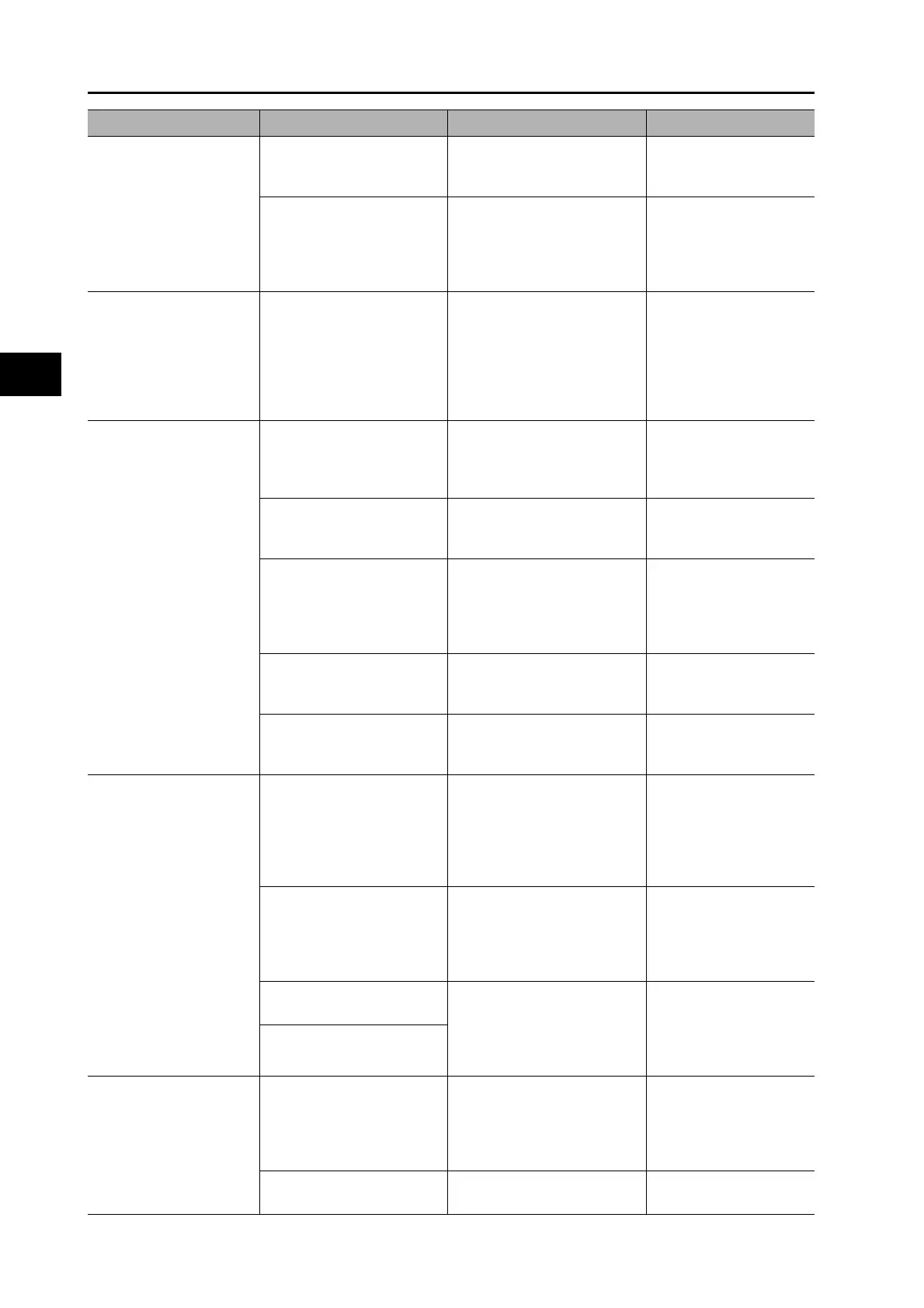

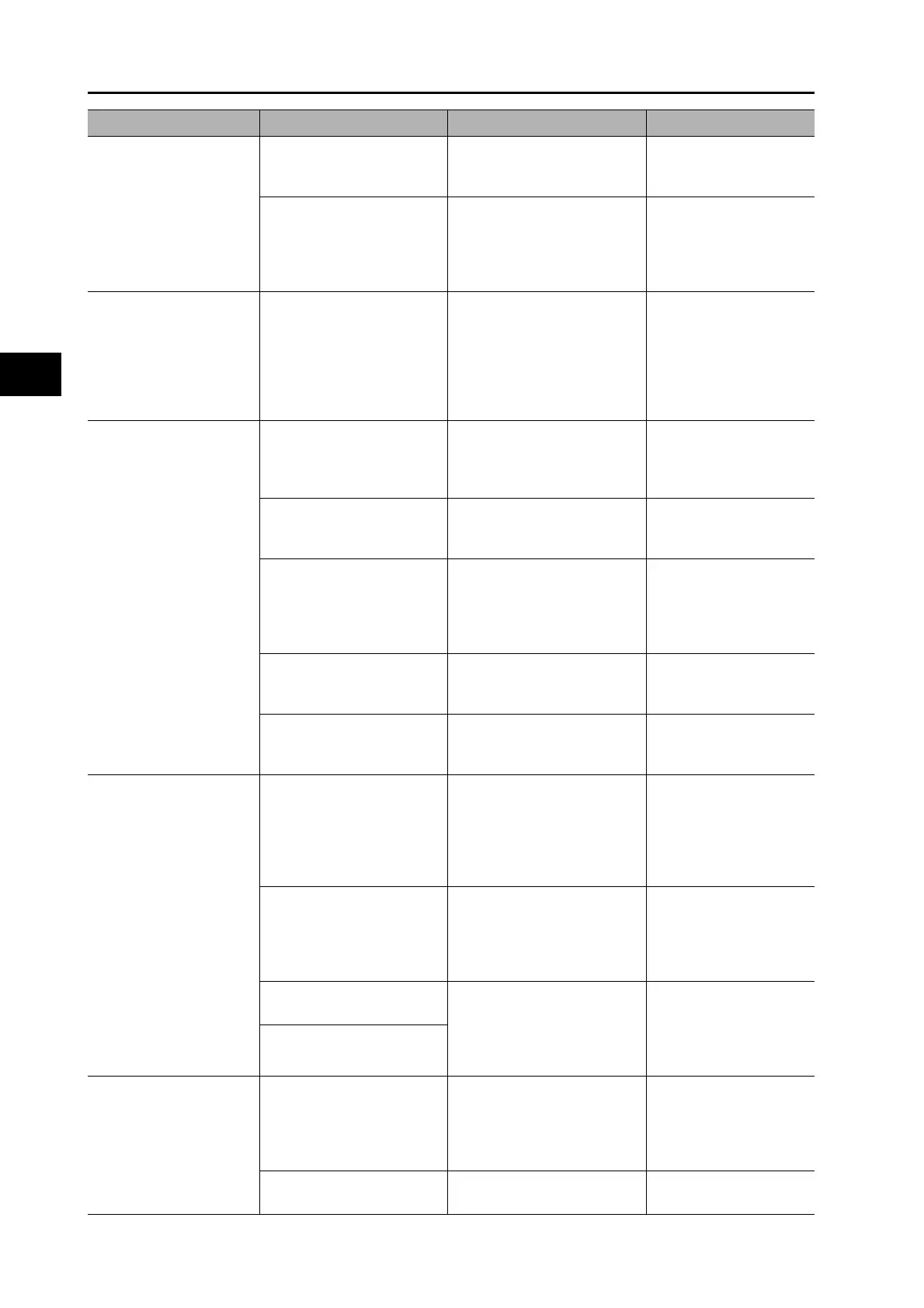

The Servomotor rotates in

the reverse direction from

the command.

The value set in the Rotation

Direction Switching (3000

hex) is incorrect.

Check the set value of object

3000 hex.

Change the set value of

object 3000 hex.

The command given by the

host controller is incorrect.

• The size of the absolute

command is set incorrect.

• The polarity of an

incremental command is set

incorrect.

• Check the actual and

target values.

• Check the rotation

direction.

The holding brake does

not work.

Power is supplied to the

holding brake.

Check to see if power is

supplied to the holding brake.

• Check the brake

interlock output (BKIR)

signal and the relay

circuit.

• Check to see if the

holding brake is worn

down.

Motor rotation is unstable. The Servomotor power

cable or encoder cable is

wired incorrectly.

Check the wiring of the

Servomotor power cable's

phases U, V, and W and check

the encoder cable's wiring.

Wire correctly.

Low rigidity is causing

vibration.

Measure the vibration

frequency of the load.

Enable the damping

control. Set the damping

filter frequency.

The load's moment of inertia

exceeds the Servo Drive's

allowable value.

Calculate the load inertia. • Check if manual tuning

can achieve proper

adjustment.

• Increase the

Servomotor capacity.

Loose joint and/or large

clearance with the machine

Check the joint with the

machine.

Remove the joint

looseness with the

machine.

The load and gain do not

match.

Check the response

waveforms for speed and

torque.

Adjust the speed loop

gain to stabilize the

rotation.

The Servomotor is

overheating.

The ambient temperature is

too high.

Check to see if the ambient

temperature around the

Servomotor is over 40°C.

• Lower the ambient

temperature around the

Servomotor to 40°C or

less. (Use a fan or air

conditioner.)

• Lower the load ratio.

The heat radiation condition

for the Servomotor is

inappropriate.

• Check to see if the specified

radiation conditions are

observed.

• For a Servomotor with a

brake, check the load ratio.

• Improve the radiation

conditions.

• Reduce the load.

• Improve ventilation.

The Servomotor is

overloaded.

Measure the torque on the

analog monitor on the front

panel or from the CX-Drive.

• Decrease the

acceleration and

deceleration rates.

• Lower the speed and

check the load.

The Servomotor vibrates

during rotation.

The machine position is

misaligned.

The coupling of the

Servomotor axis and the

machine is abnormal.

Check to see if the coupling of

the Servomotor and the

machine is misaligned.

• Tighten the coupling

again.

• Replace the coupling

with a coupling that has

no looseness.

The host controller gave a

deceleration stop command.

Check the control ladder

program in the host controller.

Review the control in the

host controller.

Symptom Probable cause Items to check Measures

Loading...

Loading...