10-4

10-2 Realtime Autotuning

OMNUC G5-SERIES AC SERVOMOTOR AND SERVO DRIVE USER'S MANUAL

10

Adjustment Functions

Setting Realtime Autotuning

1. When setting realtime autotuning, turn the servo OFF.

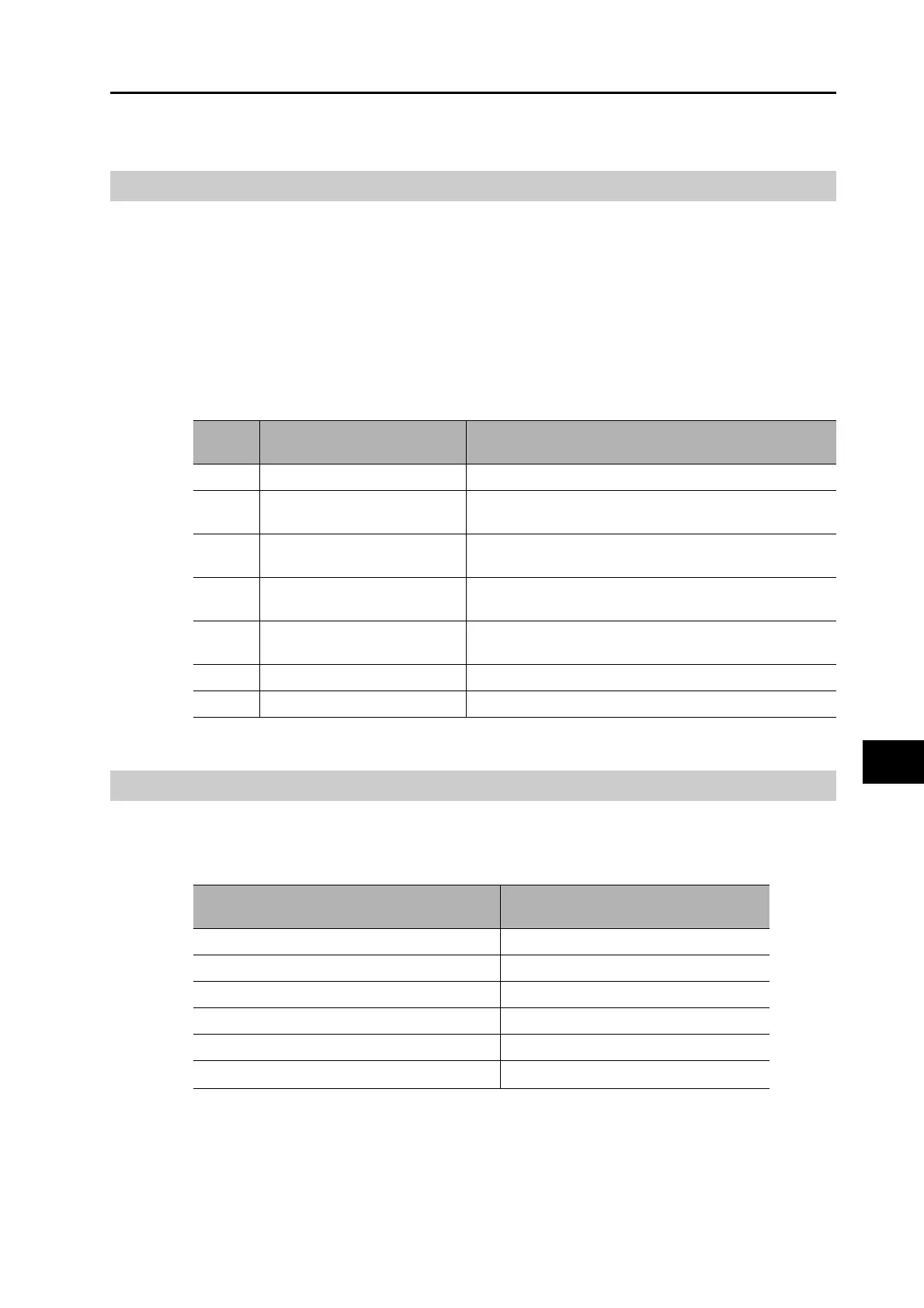

2. Set Realtime Autotuning Mode Selection (Pn002) depending on the load.

Normally, set the parameter to 1 or 2. When using a vertical axis, set the parameter to 3 or 4.

A setting of 5 is used in combination with a software tool. Do not set the parameter to 5 for

normal operation.

The gain switching function is enabled for set values 2 to 4. If Pn002 is set to 2 to 4, the

Switching Mode in Position Control (Pn115) must be set to 10 (Combination of command pulse

input and speed). The gain is switched according to this switching condition setting. Refer to

page "Gain Switching Setting for Each Control Mode" (P.6-30) for details on setting the

Switching Mode in Position Control (Pn115).

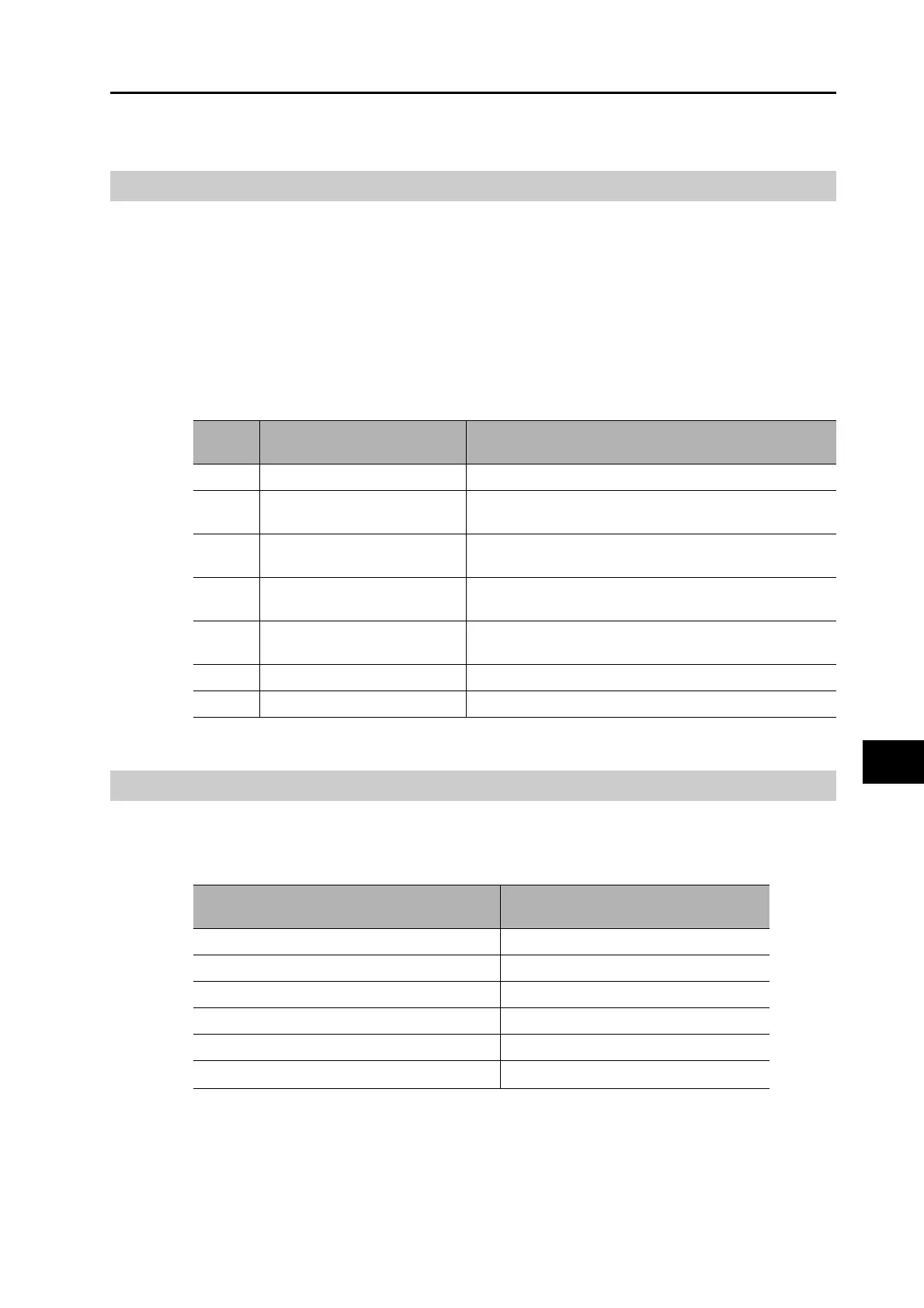

Setting Machine Rigidity

1. Set the Realtime Autotuning Machine Rigidity Selection (Pn003) according to the

table below.

Start from the lower machine rigidity number and check the operation.

2. Turn the servo ON and operate the machine with a normal pattern.

To increase responsiveness, increase the machine rigidity number, and check the response.

If vibration occurs, enable the adaptive filter and operate. If already enabled, lower the machine

rigidity number.

The adaptive filter can be left enabled even when disabling realtime autotuning after completing

adjustments. Even if the adaptive filter is disabled, the set values of notch filters 3 and 4 will be maintained.

Set

value

Realtime autotuning Description

0 Disabled Realtime autotuning is disabled.

1

Focus on stability (default

setting)

No unbalanced load, friction compensation, or gain

switching.

2 Focus on position control

Used when unbalanced load and friction are small. Gain

switching is set.

3 Vertical axis

Used when an unbalanced load is present, such as a

vertical axis.

4

Friction compensation and

vertical axis

Used when a vertical axis or other unbalanced load is

present and when friction is large.

5 Load characteristic estimation Used only for estimating load characteristics.

6 Customization Used to customize the Realtime Autotuning Mode.

Machine configuration and drive method

Realtime Autotuning

Machine Rigidity Selection (Pn003)

Ball screw direct coupling 12 to 24

Ball screw and timing belt 8 to 20

Timing belt 4 to 16

Gears, rack and pinion drives 4 to 16

Other machines with low rigidity 1 to 8

Stacker cranes Perform manual tuning.

Loading...

Loading...