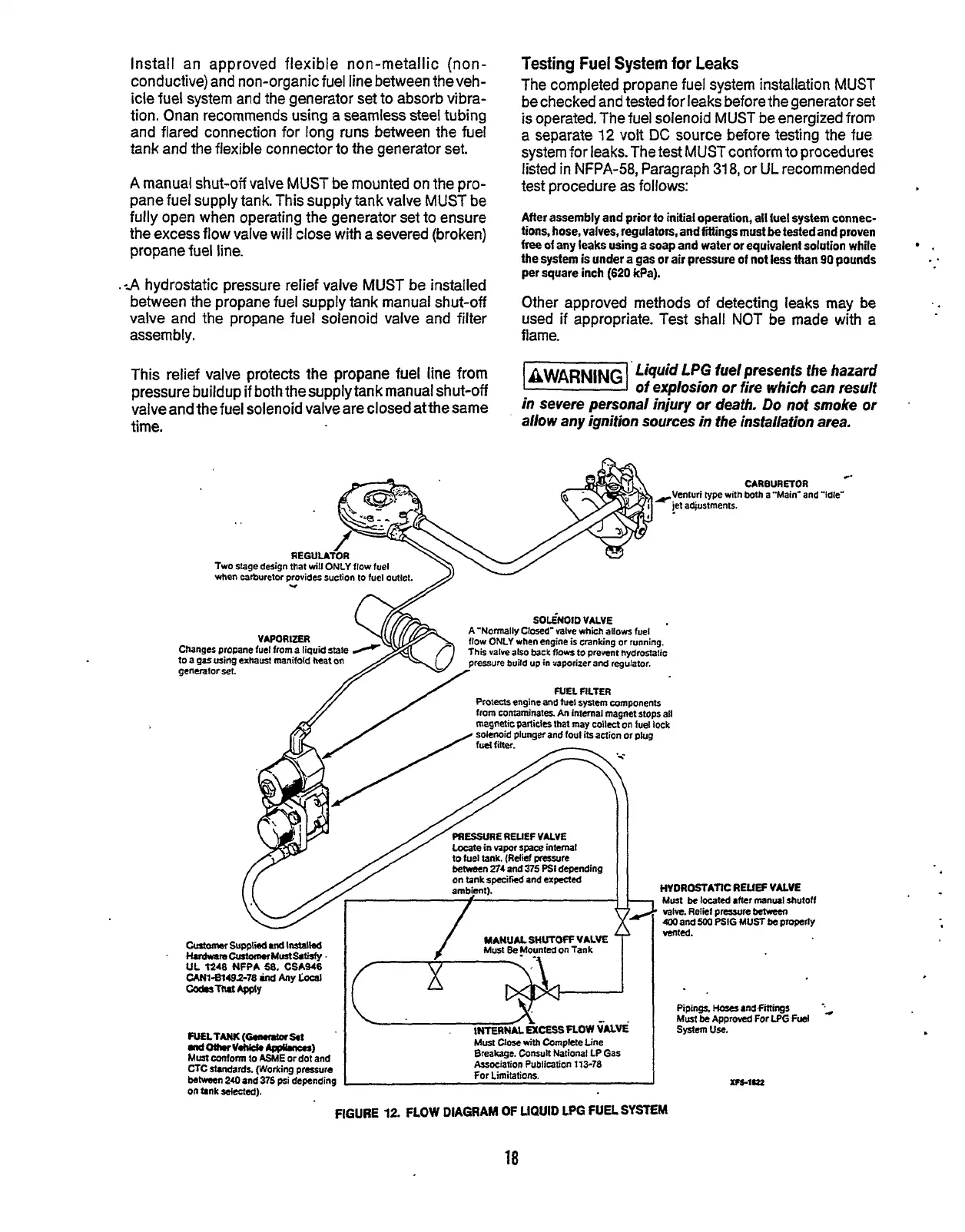

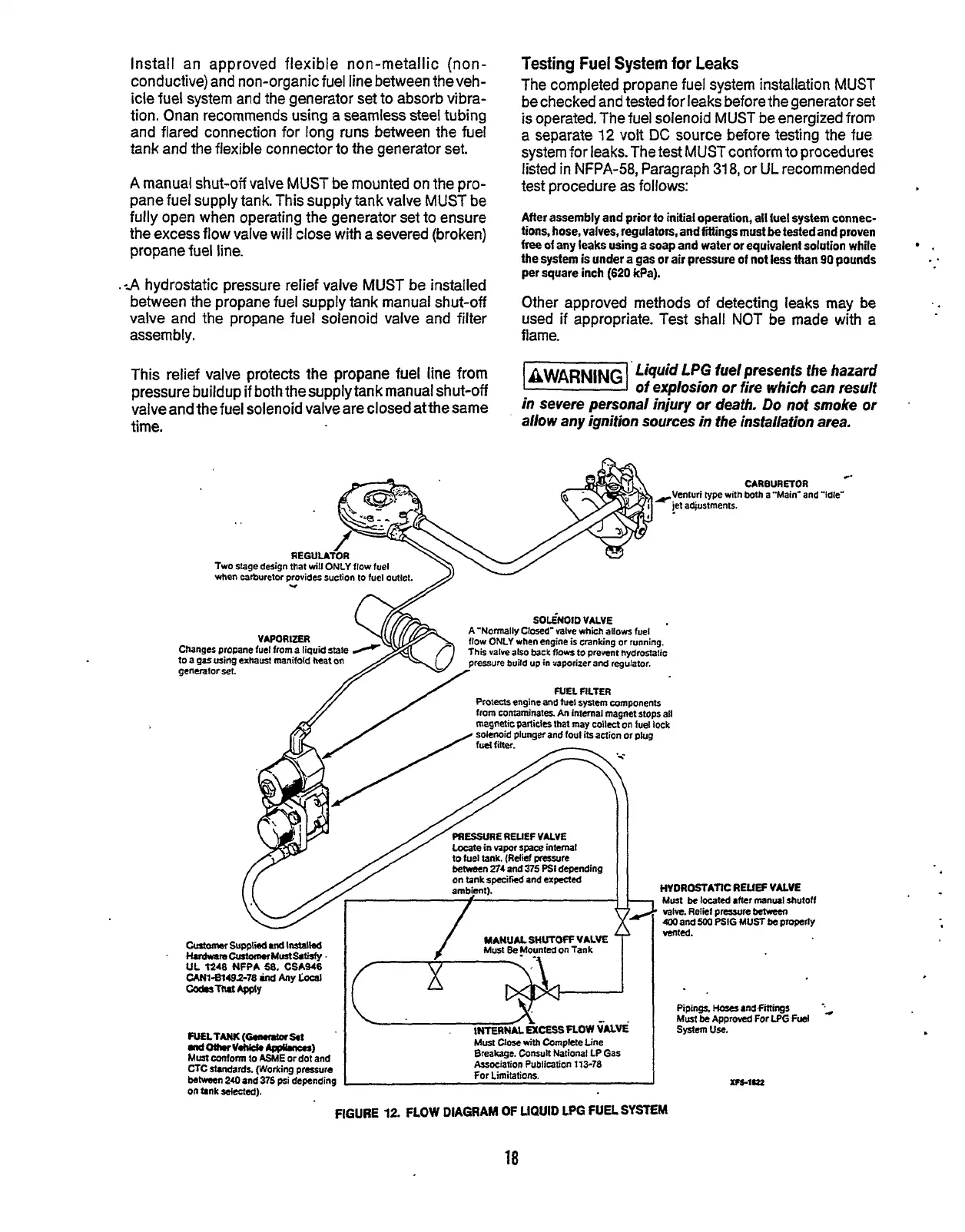

Install an approved flexible non-metallic (non-

conductive) and non-organic fuel line between theveh-

icle fuel system and the generator set to absorb vibra-

tion. Onan recommends using a seamless steel tubing

and flared connection

for

long runs between the fuel

tank and the flexible connector to the generator set.

aldotIurV~~)

Mu3

confonn

to

ASME

or dol and

CTC

slandards. (Working pressure

A

manual shut-0% valve MUST be mounted on the pro-

pane fuel supply tank. This supply tank valve

MUST

be

fully open when operating the generator set

to

ensure

the excess flow valve

will

close with a severed (broken)

propane fuel line.

Must

Close

with

Completeline

Breakage. Consult National

LP

Gas

Associalion Publication

113-78

For Limitations.

VblQZ

.-A

hydrostatic pressure relief valve MUST be installed

between the propane fuel supply tank manual shut-off

valve and the propane fuel solenoid valve and filter

assembly

.

This relief valve protects the propane fuel line from

pressure buildup if both the supply tank manual shut-off

valve and the fuel solenoid valve are closed at the same

time.

Testing

Fuel

System

for

Leaks

The completed propane fuel system installation MUST

be checked and tested for leaks before the generator set

is operated. The fuel solenoid MUST be energized from

a separate

12

volt

DC

source before testing the fue

system for leaks. The test

MUST

conform to procedure:

listed in

NFPA-58,

Paragraph

318,

or

UL recommended

test procedure as follows:

After assembly and prior

lo

initial operation,

all

iuel

system

connec-

tions, hose, valves, regulators,and fittings must

be

testedand proven

free

of

any leaks using a soap and water

or

equivalent solution while

the system

is

under

a

gas

or

air

pressure

of

not

less

than

90

pounds

per square inch

(620

kPa).

Other approved methods of detecting leaks

may

be

used if appropriate. Test shall

NOT

be made with a

flame.

.

..

Liquid

LPG

fuel presents

fhe

hazard

EiSSiEI

'

of

explosion

or

fire which can result

in severe personal injury

or

deafh.

Do

not smoke

or

allow any ignition sources in the installation area.

CARBURETOR

*l/enluri

lype

with

bolh

a "Main" and

!et adjustments.

when

carburetor provides suclion

Io

fuel

outlet.

"

C.

I

'Idle-

.w

FIGURE

12

FLOW

DIAGRAM

OF

UQUID

LPG

FUEL

SYSTEM

18

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...