Keep fuel lines awayfrom hot

engine

or exhaust areas.

This

reduces chance

of

vaporlock. Install lines

so

that

they are accessible and protected from damage. Use

metal straps without sharp edges

to

secure them.

No

&ad

Half

Load

0.5

gal/hr

0.8

gal/hr

(1.9

I/hr)

(3.0

Vhr)

Flexible

line

must

be

long

enough to allow for set

movement

in

order to prevent

binding,

stretching

or

breaking.

PROPANE

(LPG)

FUEL

SYSTEM

(60

Hz

Only)

+-

Fuel

System

Provisions

'

.-

.

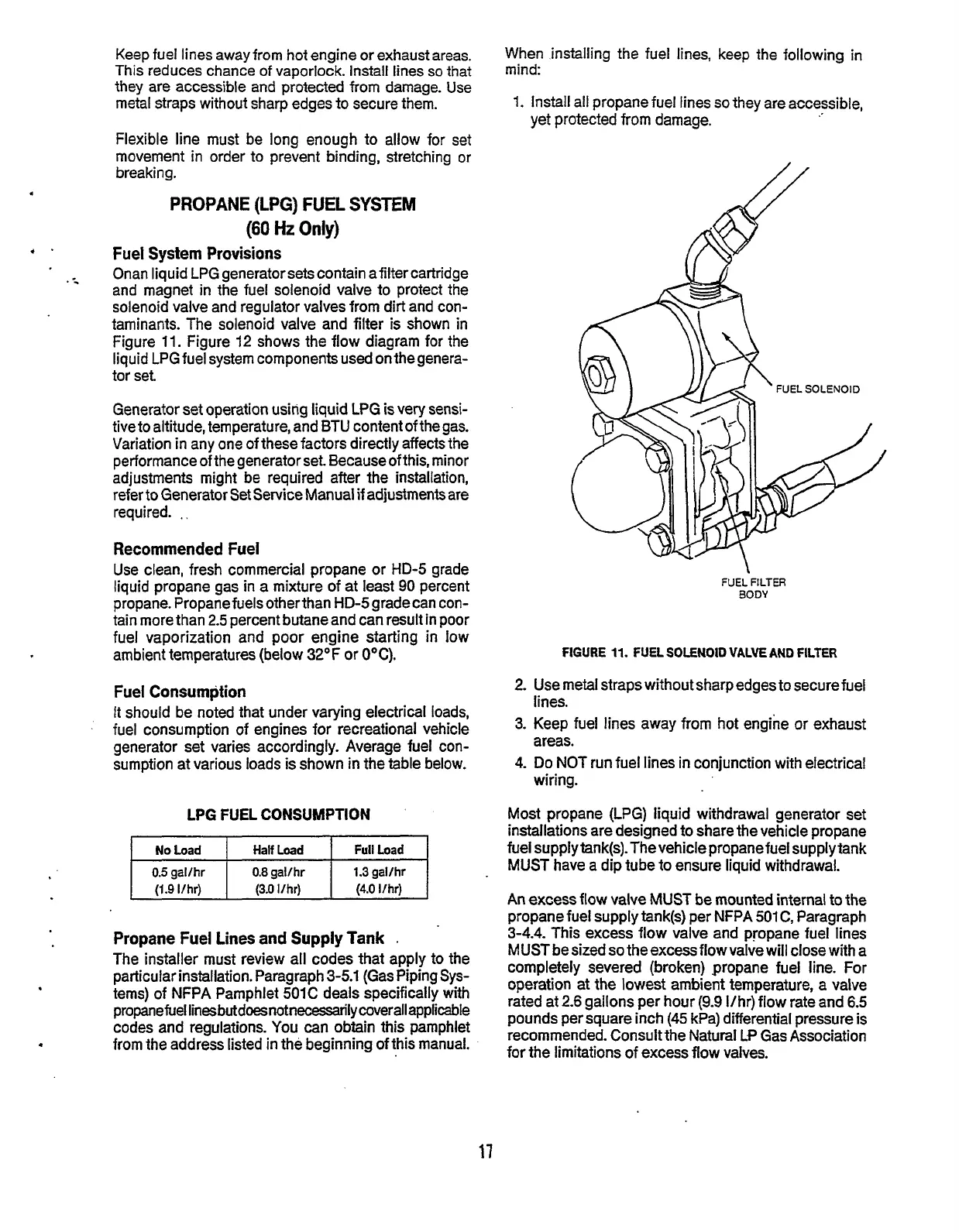

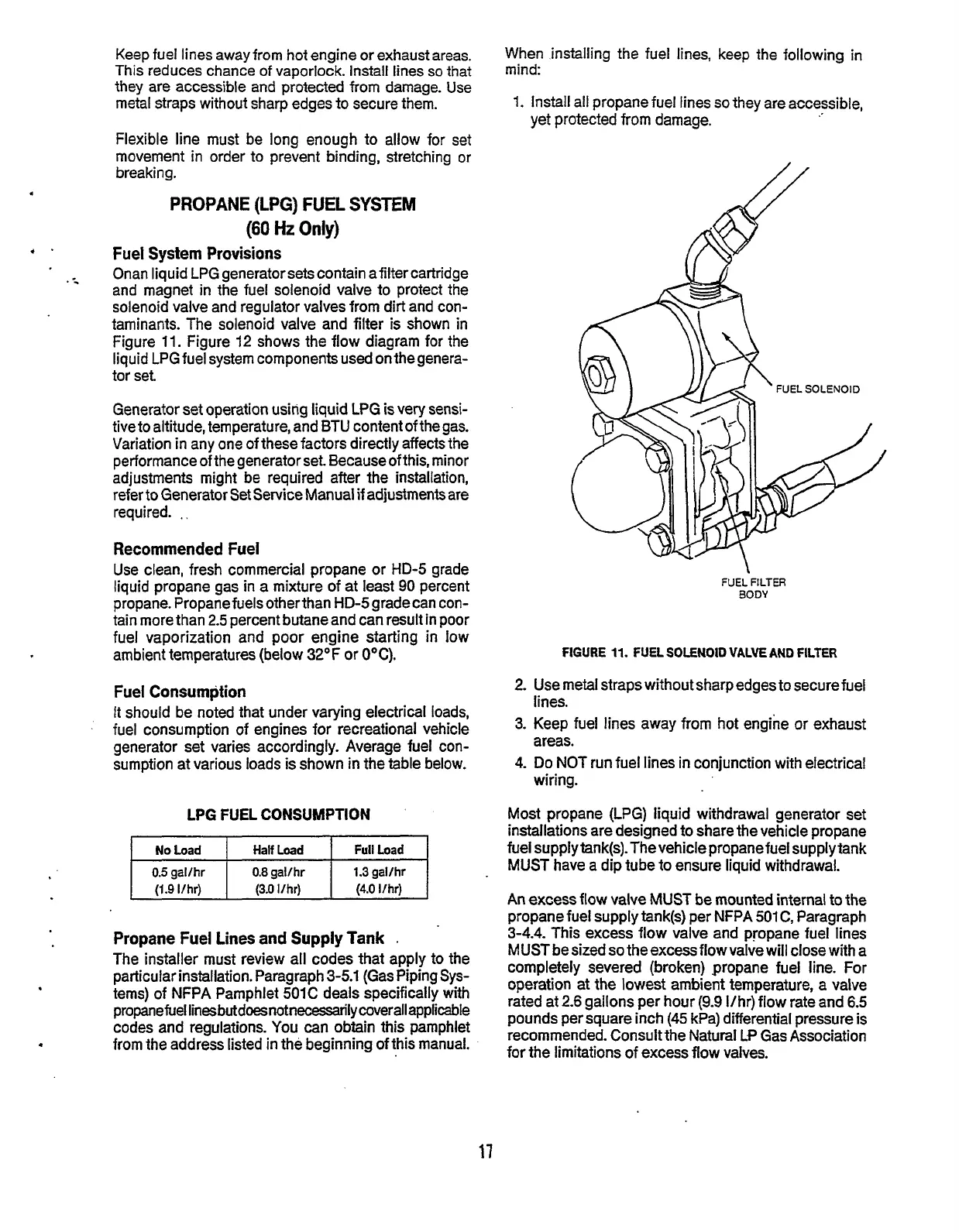

Onan

liquid

LPG

generator sets contain afiltercartridge

and magnet

in

the fuel solenoid valve to protect

the

solenoid valve and regulator valves from

dirt

and con-

taminants. The solenoid valve and

filter

is

shown

in

Figure

11.

Figure

12

shows the flow

diagram

for

the

liquid

LPG

fuel system components

used

on thegenera-

tor

set

Full

Load

1.3 gal/hr

(4.0

I/hr)

Generator set operation

using

liquid

LPG

is

very

sensi-

tive to altitude, temperature, and

BTU

content of

the

gas.

Variation

in

any one of these factors directly affects the

performance of the generator

set.

Because of

this,

minor

adjustments

might

be

required

after the installation,

refer to Generator Set Service

Manual

if

adjustmentsare

required.

.,

Recommended

Fuel

Use clean, fresh commercial propane or

HD-5

grade

liquid

propane gas

in

a

mixture

of

at

least

90

percent

propane. Propane

fuels

otherthan

HD-5

gradecan con-

tain more than

2.5

percent butane and can

result

in

poor

fuel vaporization

and

poor

engine

starting

in

low

ambient temperatures (below 32°F or

OOC).

Fuel Consumption

It

should

be

noted that under varying electrical loads,

fuel consumption of engines for recreational vehicle

generator set varies accordingly. Average fuel con-

sumption

at

various loads

is

shown

in

the table below.

LPG

FUEL

CONSUMPTION

Propane Fuel

Lines

and

Supply

Tank

.

The installer

must

review

all

codes that apply to the

particular installation. Paragraph

3-5.1

(Gas

Piping

Sys-

tems)

of

NFPA

Pamphlet

501C

deals specifically

with

propane fuel

linesbutdoesnotnecessady

coverall applicable

codes and regulations. You

can

obtain this

pamphlet

from

the

address

listed

in

the beginning of

this

manual.

When

installing

the fuel

lines,

keep the following

in

mind:

1.

Install all propane fuel

lines

so

they are accessible,

yet

protected

from

damage.

2.

3.

4.

FUEL

FILTER

BODY

FIGURE

11.

FUEL

SOLENOlO

VALVE

AND

FILTER

Use

metal

straps

withoutsharpedges to securefuel

lines.

Keep

fuel

lines

away from hot engine or exhaust

areas.

Do

NOT

run

fuel

lines

in

conjunction

with

electrical

wiring.

Most propane

(LPG)

liquid

withdrawal generator set

installations are designed to share the vehicle propane

fuel

supplytank(s).

The

vehicle

propane fuel

supply

tank

MUST

have a dip tube to

ensure

liquid

withdrawal.

An

excess

flow

valve

MUST

be

mounted internal

to

the

propane

fuel

supplytank(s)

per

NFPA

501

C,

Paragraph

3-4.4.

This

excess

flow

valve

and propane fuel lines

MUST be sized

so

the

excess

flow

valve

will

close

with

a

completely

severed

(broken) propane fuel line. For

operation at the lowest ambient temperature, a valve

rated at

2.6

gallons per hour

(9.9

Vhr)

flow rate and

6.5

pounds

per

square

inch

(45

kPa) differential

pressure

is

recommended. Consult the

Natural

LP Gas Association

for

the

limitations of excess

flow

valves.

17

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...