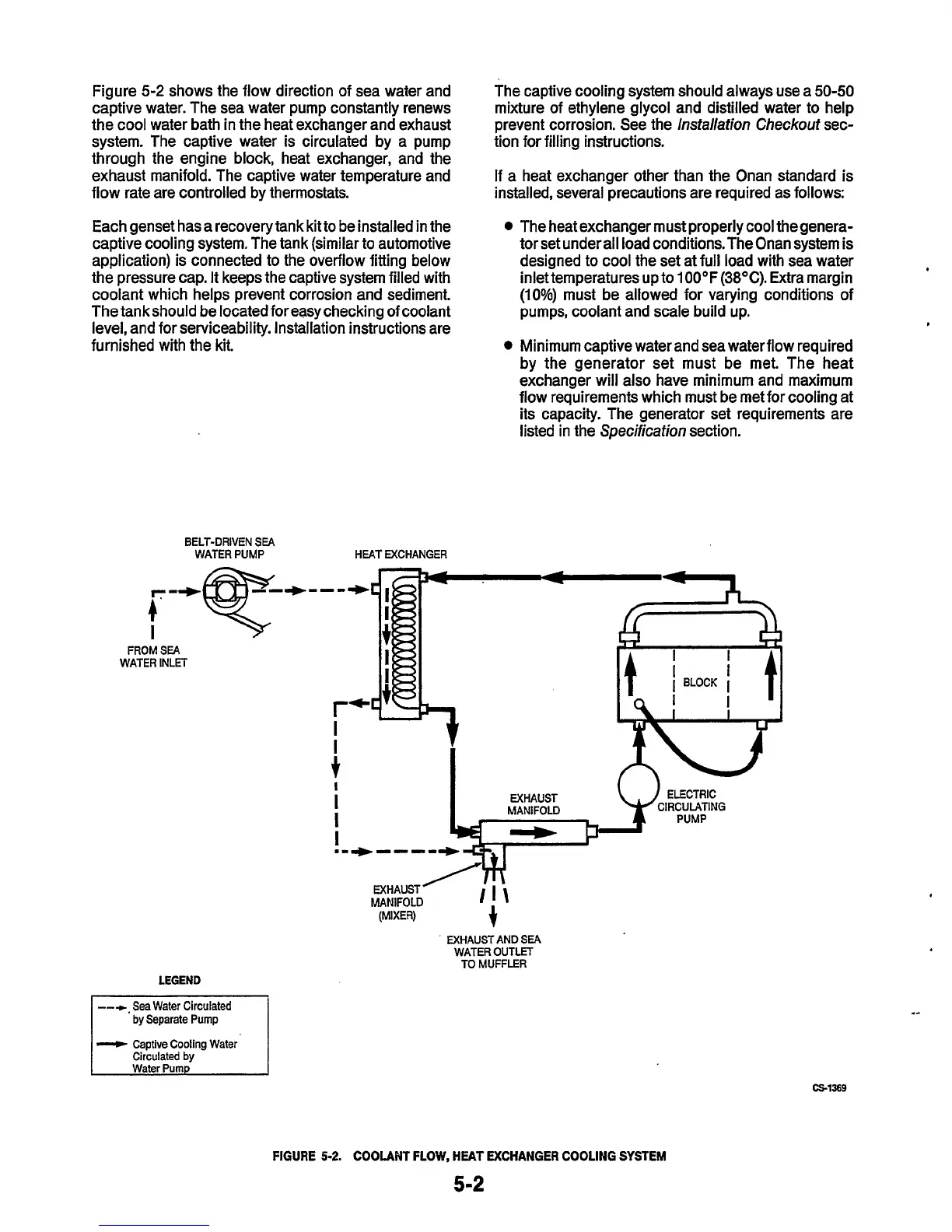

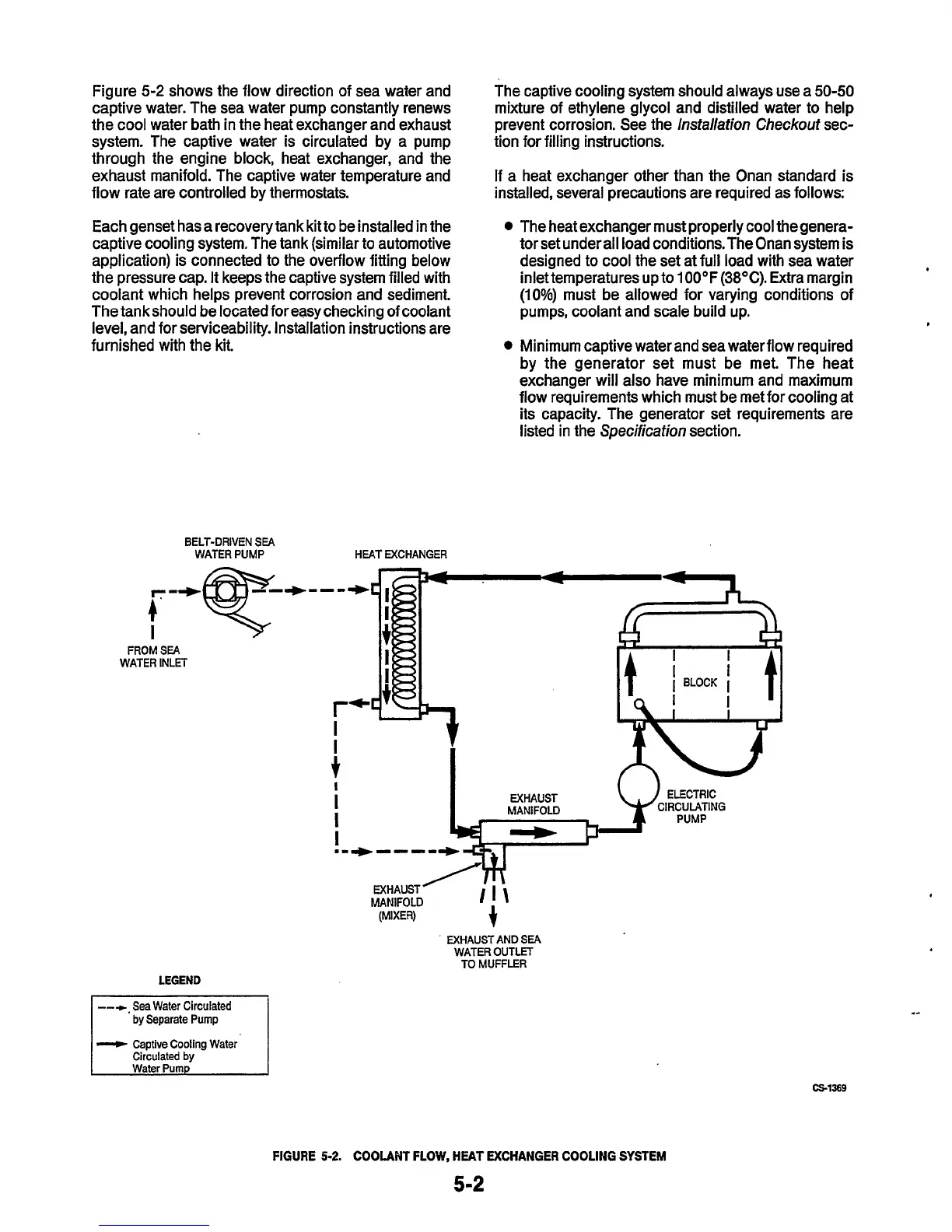

Figure

5-2

shows the flow direction of sea water and

captive water. The sea water pump constantly renews

the cool water bath in the heat exchanger and exhaust

system. The captive water is circulated by a pump

through the engine block, heat exchanger, and the

exhaust manifold. The captive water temperature and

flow rate are controlled

by

thermostats.

Each genset has a recoverytank kit to be installed in the

captive cooling system. The tank (similar to automotive

application) is connected to the overflow fitting below

the pressure cap. It keeps the captive system filled with

coolant which helps prevent corrosion and sediment.

The tankshould be locatedforeasychecking

of

coolant

level, and for serviceability. lnstallation instructions are

furnished with the kit.

BELT-DRIVEN

SEA

WATER PUMP HEAT EXCHANGER

r-

I

FROM

SEA

WATER INLET

The captive cooling system should always use a

50-50

mixture of ethylene glycol and distilled water to help

prevent corrosion. See the

lnstallation Checkout

sec-

tion for filling instructions.

If a heat exchanger other than the Onan standard is

installed, several precautions are required as follows:

The heat exchanger must properly cool thegenera-

tor set under all load conditions.The Onan system is

designed to cool the set at full load with sea water

inlet temperatures up

to

1

OOOF

(38OC).

Extra margin

(10%)

must be allowed for varying conditions of

pumps, coolant and scale build up.

Minimum captive water and sea water flow required

by the generator set must be met. The heat

exchanger will also have minimum and maximum

flow requirements which must be met for cooling at

its capacity. The generator set requirements are

listed in the

Specificafion

section.

r*

I

I

t

I

I

I

I

.-*----

t

MANIFOLD

(MIXER)

EXHAUST AND

SEA

WATER OUTLET

TO

MUFFLER

by Separate Pump

--P

Captive Cooling Water

Circulated by

cs1369

....

FIGURE

5-2.

COOLANT

FLOW, HEAT EXCHANGER COOLING SYSTEM

5-2

Loading...

Loading...