.

Section

7.

Fuel

System

GENERAL

Fuel leakage in boats presents fire

-1

and explosion hazards that can

result in severe personal injury

or

death.

For

this rea-

son,

it is important that the material, design, consfruc-

tion and installation of all fuel system components

meet the highest possible standards. Use only pro-

ducts specified

for

marine application.

Make sure all fuel lines are properly supported and

connections tightened securely. Use an approved pipe

joint compound acceptable for use with gasoline fuel at

all thread fittings.

Fuel distribution lines must have as few connections as

practicable, and be protected against mechanical injury

and vibration. In all fuel system installations, cleanliness

is very important. Take precautions to prevent the

entrance of moisture, dirt or contaminants of any kind

during installation.

If

possible, avoid the use of fuels composed of blends of

gasoline and alcohol. Methanol notably can cause cor-

rosion of metals and damage to plastic and rubber.

Some blended fuels may have cosolvents in them to

prevent damage, but the suitability of these fuels is not

fully known at thistime. Fuel containing alcohol can also

cause external paint damage

if

spilled during refueling.

Some states require the use of labels on pumps to indi-

cate alcohol content If unsure, ask the fuel station

operator.

INSTALLATION

Any flexible fuel line installed between the fuel tank and

the generator set must meet USCG requirement

33CFR183.558 and be stamped

“USCG

TYPEA”.

There

cannot be an electrical connection between the hose

end fittings. A bad ground in the cranking circuit will

cause a wire reinforced hose to become hot and ignite

the fuel during cranking. If a metallic fuel line is run into

the generator set compartment, a length of flexible hose

meeting the above specifications must be installed to

absorb vibration from the generator set.

Ignition

of

fuel can cause fire and

severe personal injury or death. Be

sure any flexible fuel line used between the fuel tank

and the generator

set

meets

USCG

requirement

33CFR183.558

and

is

stamped

“USCG

TYPE

A”.

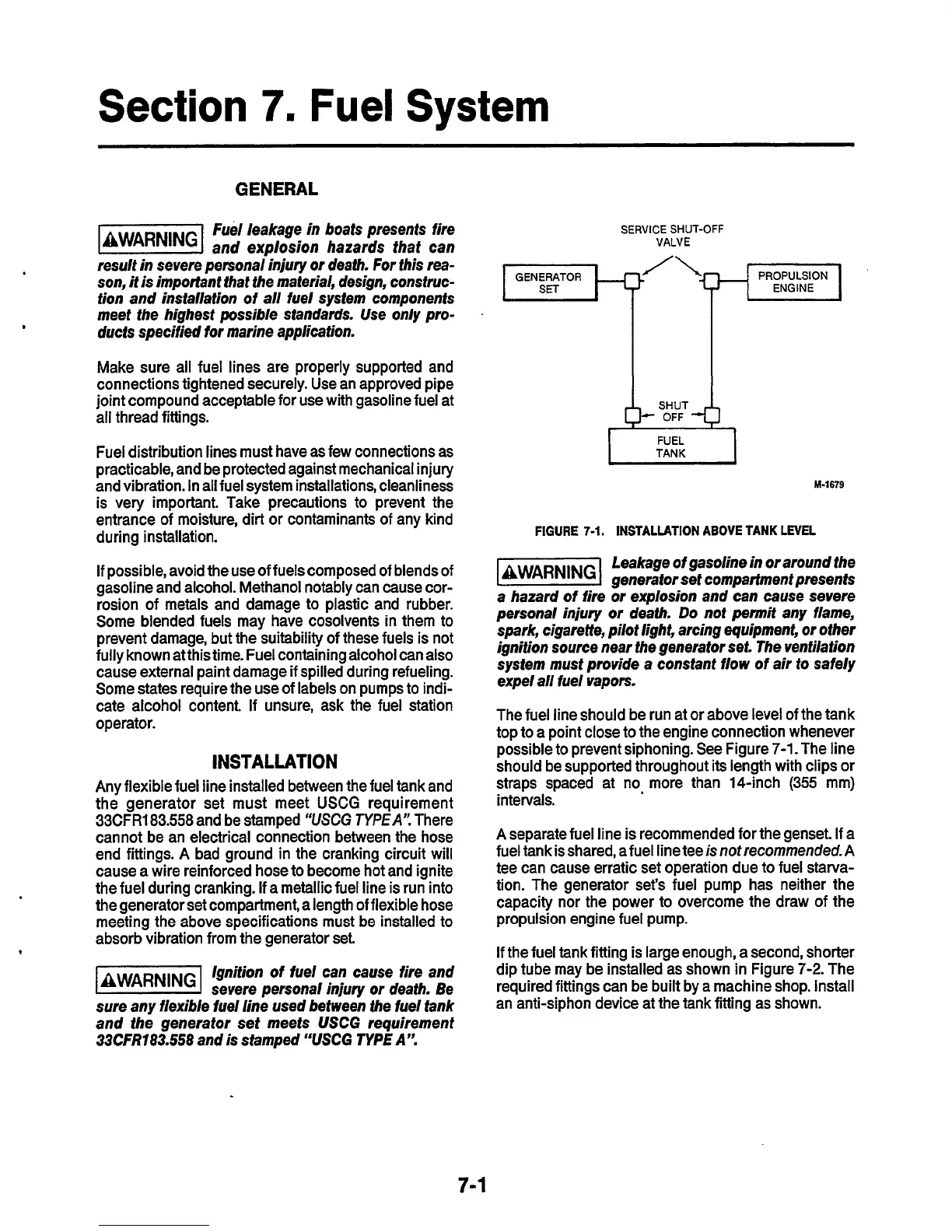

SERVICE

SHUT-OFF

VALVE

PROPULSION

ENGINE

GENERATOR

FUEL

TANK

FIGURE

7-1.

I

I

M-1679

INSTALLATION ABOVE TANK LEVEL

Leakage

of

gasoline in

or

around the

generator

set compartment presents

a hazard

of

fire

or

explosion and can cause severe

personal injury

or

death.

Do

not

permit

any flame,

spark, cigarette, pilot light, arcing equipment,

or

other

ignition source near fhe generator set. The ventilation

system must provide a constant flow

of

air

to

safely

expel all fuel vapors.

The fuel line should be run at

or

above level of the tank

top to a point close to the engine connection whenever

possible to prevent siphoning. See Figure 7-1.The line

should be supported throughout its length with clips

or

straps spaced at no more than 14-inch (355 mm)

intervals.

A

separate fuel line is recommended for the genset. If a

fuel tank is shared, afuel linetee isnotrecommended-A

tee can cause erratic set operation due to fuel starva-

tion. The generator set’s fuel pump has neither the

capacity nor the power to overcome the draw of the

propulsion engine fuel pump.

If the fuel tank fitting is large enough, a second, shorter

dip tube may be installed as shown in Figure

7-2.

The

required fittings can be built by a machine shop. Install

an anti-siphon device at the tank fitting as shown.

Loading...

Loading...