FUEL LINES

The proper installation of fuel lines is very important

Give special attention to the following requirements.

0

All

fuel line materials must meetthe requirementsof

both the USCG and the ABYC.

0

Solid fuel lines must be seamless annealed, double-

flared, and approved for marine installations.

0

Run fuel lines at the top level of tank to a point as

close to the engine as possible to reduce danger of

fuel siphoning should the line break.

areas. This reduces chance of vapor lock.

I

.

0

Keep fuel lines away from hot engine or exhaust

0

Any locked-in torsional stresses must be avoided in

the fuel line.

0

Install a flexiblefuel line meeting USCG requirement

33CFR183.558, and stamped

“USCG

TYPE

A”

between the solid fuel line and engine to absorb

vibration. The line length must be sufficient to pre-

vent binding or stretching due to generator set

movement.

,

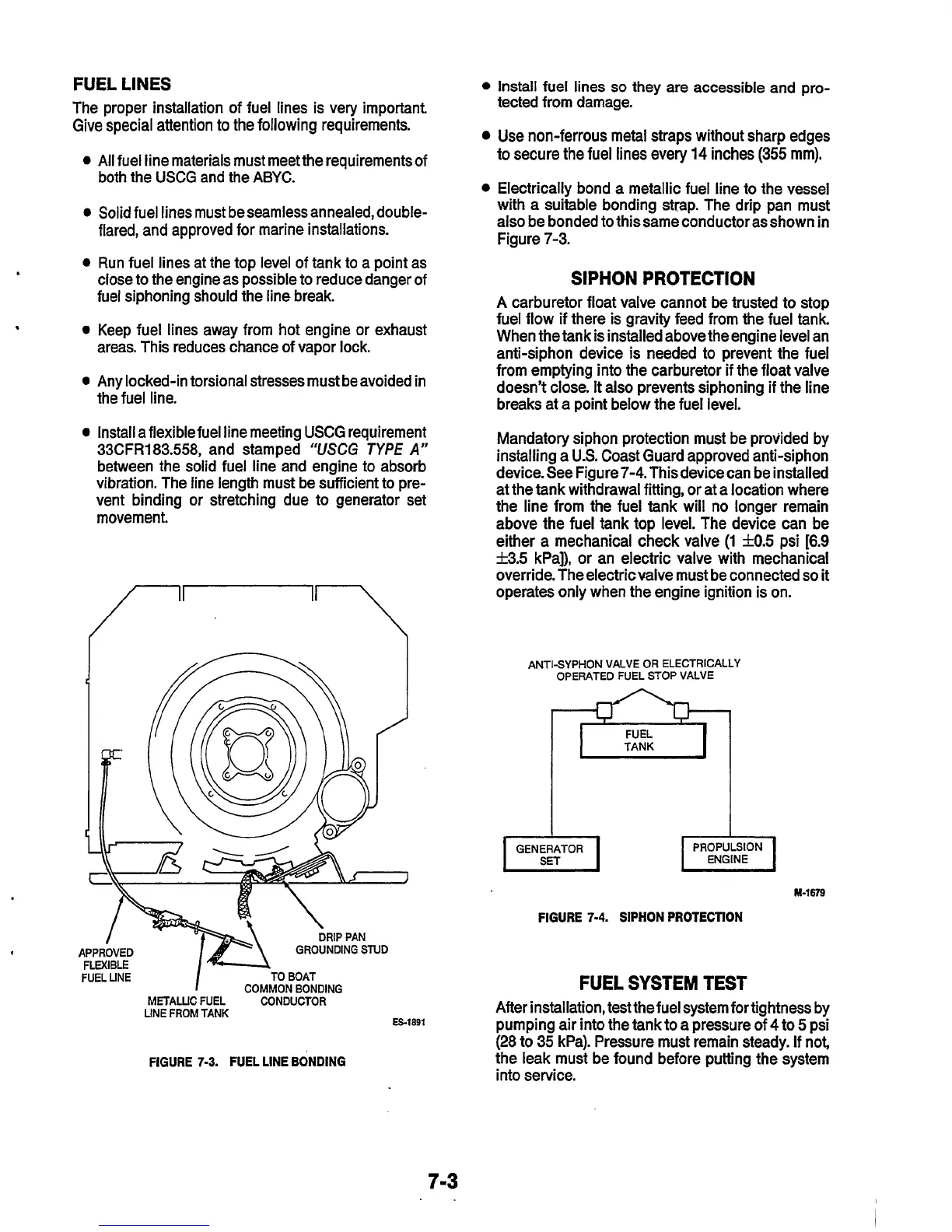

FUEL LINE

I

TO

BOAT

I

COMMON BONDING

METALLIC

FUEL

CONDUCTOR

LINE FROM TANK

ES-1891

FIGURE 7-3. FUEL LINE BONDING

Install fuel lines

so

they

are

accessible and pro-

tected from damage.

Use non-ferrous metal straps without sharp edges

to secure the fuel lines every

14

inches

(355

mm).

Electrically bond a metallic fuel line to the vessel

with a suitable bonding strap. The drip pan must

also be bonded to thissame conductor asshown in

Figure 7-3.

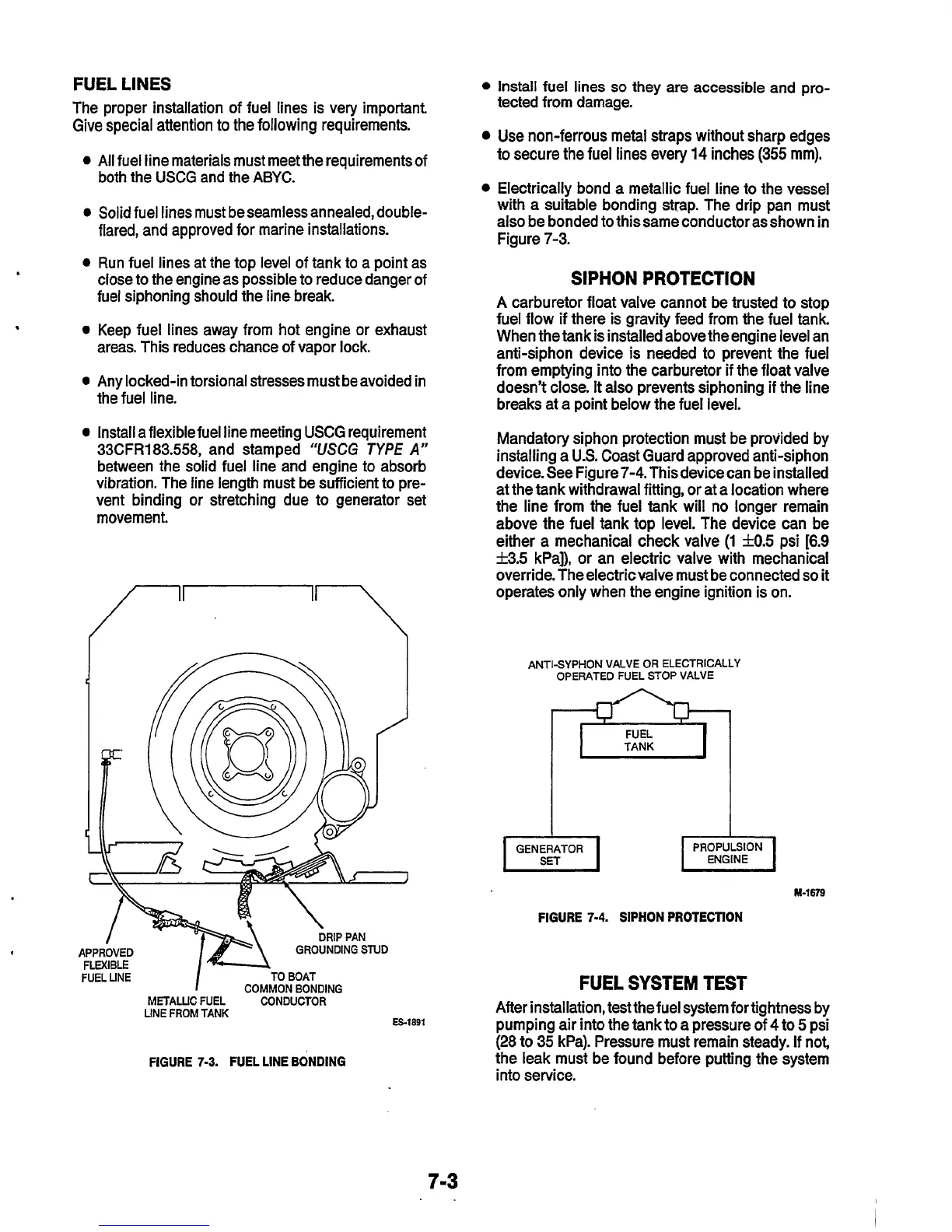

SIPHON

PROTECTION

A carburetor float valve cannot be trusted to stop

fuel flow if there is gravity feed from the fuel tank.

When the tank is installed above the engine level an

anti-siphon device is needed to prevent

the

fuel

from emptying into the carburetor if the float valve

doesn’t close.

It

also prevents siphoning if the line

breaks at a point below the fuel level.

Mandatory siphon protection must be provided by

installing a

U.S.

Coast Guard approved anti-siphon

device. See Figure

7-4.

This device can be installed

at the tank withdrawal fitting, or at a location where

the line from the fuel tank will no longer remain

above the fuel tank top level. The device can be

either a mechanical check valve

(1

f0.5

psi

[6.9

53.5

kPa]), or an electric valve with mechanical

override. The electricvalve must be connected

so

it

operates only when the engine ignition is on.

ANTISYPHON VALVE OR ELECTRICALLY

OPERATED FUEL STOP VALVE

M-1679

FIGURE

7-4.

SIPHON PROTECTION

FUEL SYSTEM TEST

After installation, test thefuel system fortightness by

pumping air into the tank to a pressure Of

4

to

5

psi

(28 to 35 kPa). Pressure must remain steady. If not,

the leak must be found before putting the system

into service.

7-3

Loading...

Loading...