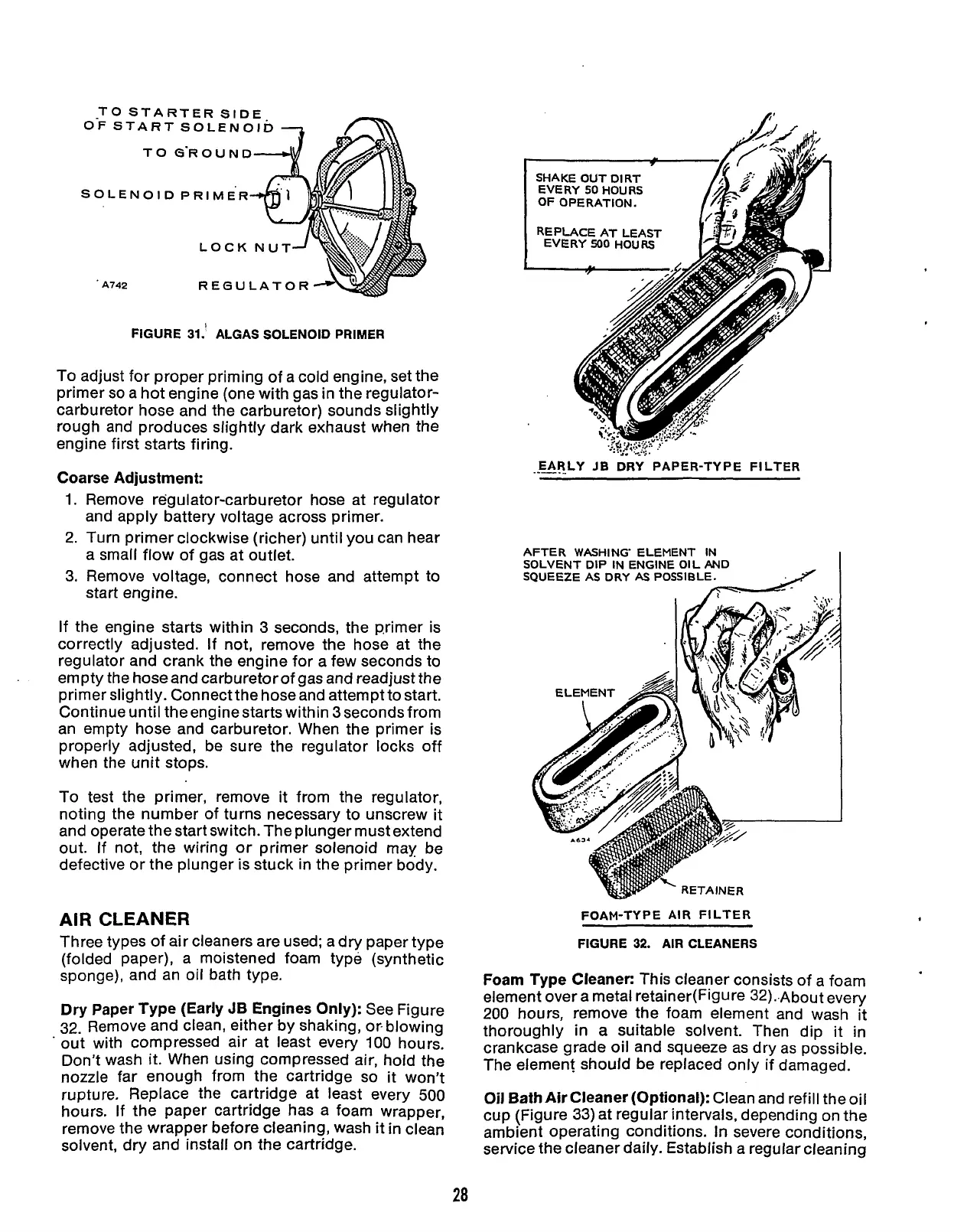

TO STARTER SIDE

OF

START

SOLENOI~

TO G‘ROUND

SOLENOID PRIMER

’

A742

REGULATOR

FIGURE

31.’

ALGAS SOLENOID PRIMER

To

adjust for proper priming of a cold engine, set the

primer

so

a hot engine (one with gas in the regulator-

carburetor hose and the carburetor) sounds slightly

rough and produces slightly dark exhaust when the

engine first starts firing.

Coarse Adjustment:

1.

Remove regulator-carburetor hose at regulator

2.

Turn primer clockwise (richer) until you can hear

3. Remove voltage, connect hose and attempt to

If the engine starts within 3 seconds, the p.rimer is

correctly adjusted.

If

not, remove the hose at the

regulator and crank the engine for a few seconds to

empty the hoseand carburetorof gas and readjust the

primer slightly. Connect the hose and attempt to start.

Continue until the enginestarts within 3 secondsfrom

an empty hose and carburetor. When the primer is

properly adjusted, be sure the regulator locks off

when the unit stops.

and apply battery voltage across primer.

a small flow of gas at outlet.

start engine.

.

To

test the primer, remove it from the regulator,

noting the number of turns necessary to unscrew

it

and operate the start switch. The plunger must extend

out. If not, the wiring or primer solenoid may be

defective or the plunger is stuck in the primer body.

AIR

CLEANER

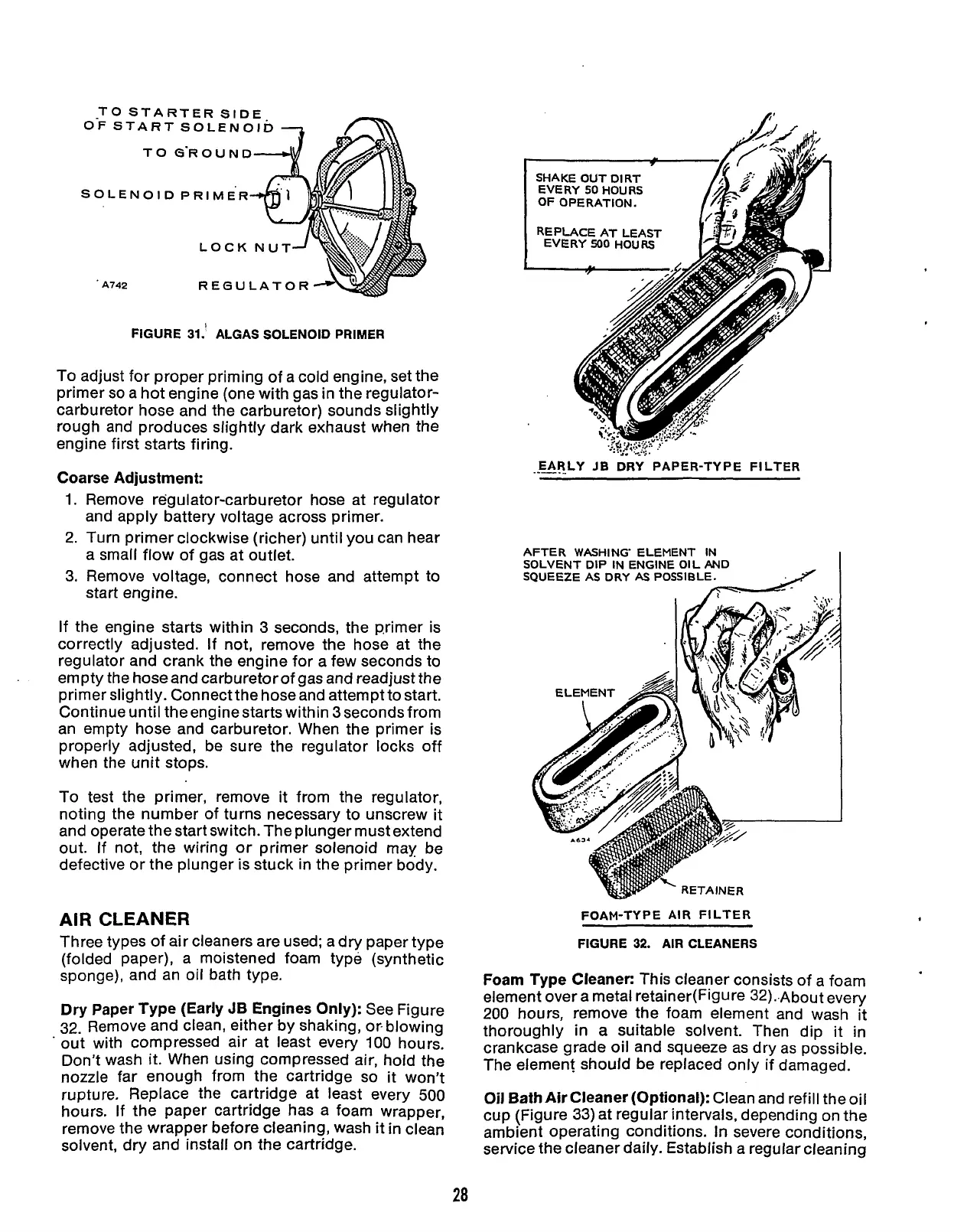

Three types of air cleaners are used; a dry paper type

(folded paper), a moistened foam type (synthetic

sponge), and an oil bath type.

Dry

Paper Type (Early

JB

Engines Only):

See Figure

32. Remove and clean, either by shaking,

or.

blowing

out with compressed air at least every

100

hours.

Don’t wash it. When using compressed air, hold the

nozzle far enough from the cartridge

so

it won’t

rupture, Replace the cartridge at least every 500

hours.

If

the paper cartridge has a foam wrapper,

remove the wrapper before cleaning, wash

it

in clean

solvent, dry and install on

the

cartridge.

EARLY

JB

DRY PAPER-TYPE FILTER

AFTER WASHING ELEMENT IN

SOLVENT DIP IN ENGINE

01

L AND

SQUEEZE

AS

DRY

AS

POSSIBLE

FOAM-TYPE

AIR

FILTER

FIGURE

32.

AIR

CLEANERS

Foam Type Cleaner:

This cleaner consists of a foam

element over a metal retainer(Figure 32)..About every

200 hours, remove the foam element and wash

it

thoroughly in

a

suitable solvent. Then dip

it

in

crankcase grade oil and squeeze as dry as possible.

The element should be replaced only if damaged.

Oil Bath Air Cleaner (Optional):

Clean and refill the oil

cup (Figure 33) at regular intervals, depending on the

ambient operating conditions.

In

severe conditions,

service the cleaner daily. Establish a regular cleaning

28

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...