SOLENOID

SOLENOID PLUNGER

SHIFTING

1

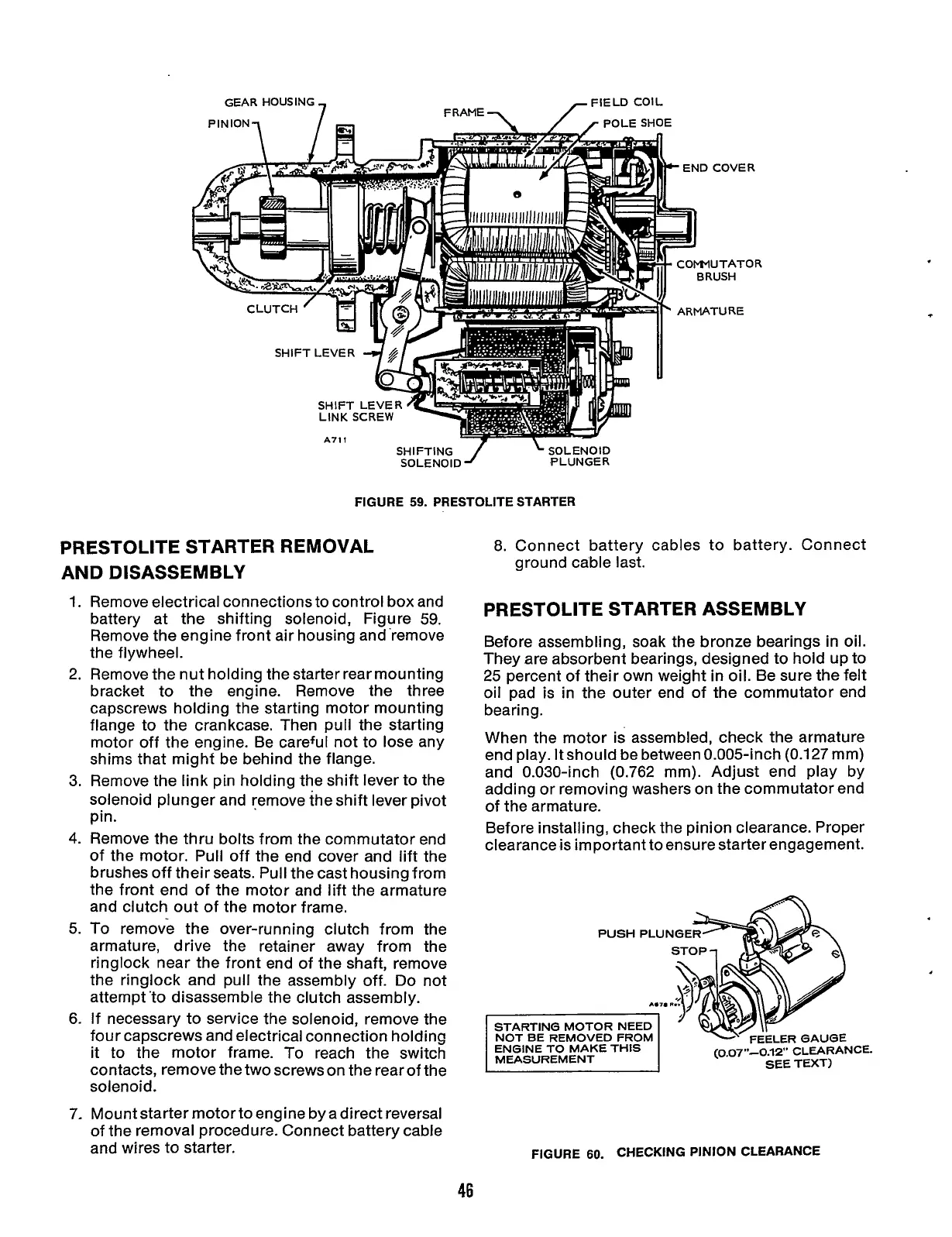

FIGURE

59.

PRESTOLITE STARTER

PRESTOLITE STARTER REMOVAL

AND DISASSEMBLY

8.

Connect battery cables to battery. Connect

ground cable last.

1.

2.

3.

4.

5.

6.

7.

Remove electrical connections to control box and

battery at the shifting solenoid, Figure

59.

Remove the engine front air housing and'remove

the flywheel.

Remove the nut holding the starter rear mounting

bracket to the engine. Remove the three

capscrews holding the starting motor mounting

flange to the crankcase. Then pull the starting

motor off the engine. Be careful not to lose any

shims that mighf be behind the flange.

Remove the link pin holding the shift lever to the

solenoid plunger and remove the shift lever pivot

pin.

Remove the thru bolts from the commutator end

of the motor. Pull off the end cover and lift the

brushes off their seats. Pull the cast housing from

the front end of the motor and lift the armature

and clutch out of the motor frame.

To

remove the over-running clutch from the

armature, drive the retainer away from the

ringlock near the front end of the shaft, remove

the ringlock and pull the assembly off.

Do

not

attempt 'to disassemble the clutch assembly.

If necessary to service the solenoid, remove the

four capscrews and electrical connection holding

it to the motor frame.

To

reach the switch

contacts, remove the two screws on the rear of the

solenoid.

Mount starter motorto engine by a direct reversal

of

the removal procedure. Connect battery cable

and wires to starter.

PRESTOLITE STARTER ASSEMBLY

Before assembling, soak the bronze bearings in oil.

They are absorbent bearings, designed to hold

up

to

25 percent of their own weight

in

oil. Be sure the felt

oil pad is in the outer end of the commutator end

bearing.

When the motor is assembled, check the armature

end play. It should be between 0.005-inch (0.127 mm)

and 0.030-inch

(0.762

mm). Adjust end play by

adding or removing washers on the commutator end

of the armature.

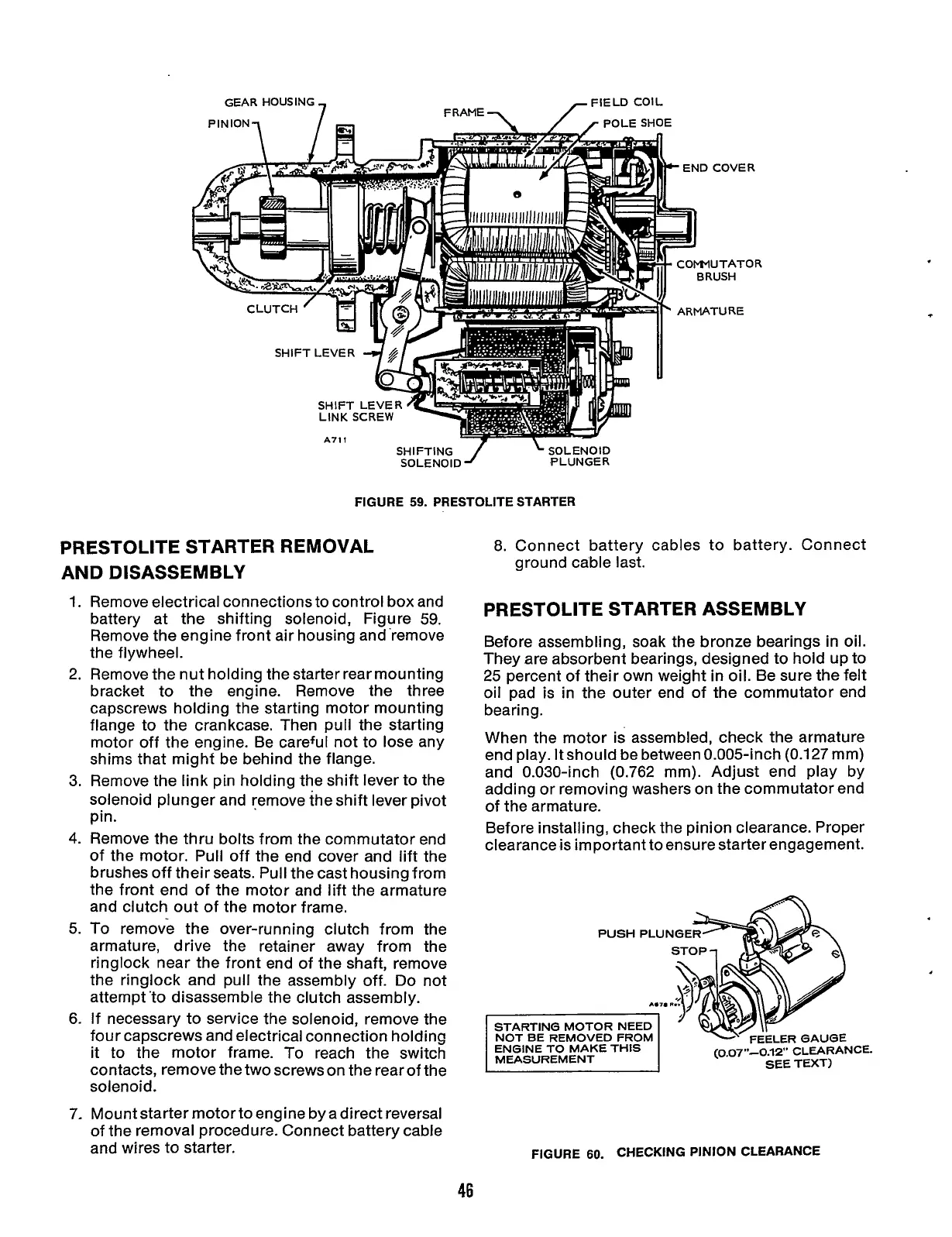

Before installing, check the pinion clearance. Proper

clearance is important to ensure starter engagement.

NOT BE REMOVED FROM

ENGINE TO MAKE

THIS

MEASUREMENT SEE TEXT)

(0.07~*-0.12"

CLEARANCE.

FIGURE

60.

CHECKING PINION CLEARANCE

46

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...